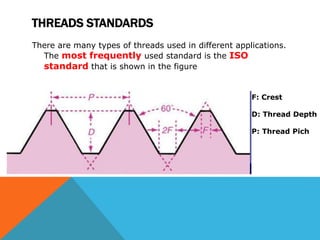

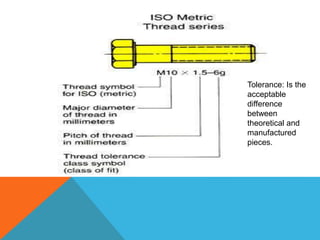

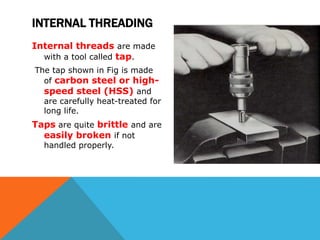

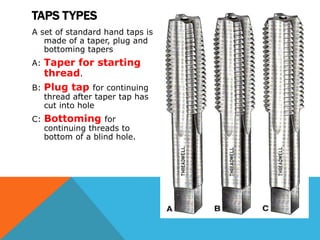

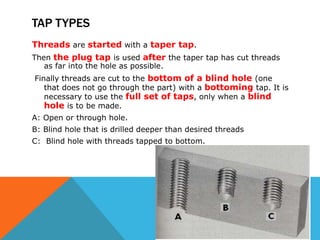

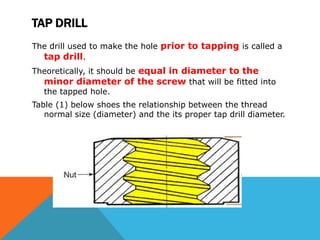

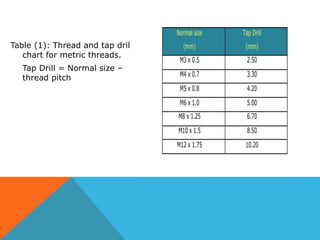

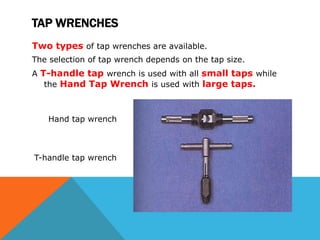

This document discusses tapping and threading processes. It aims to explain tapping, differentiate thread classes, identify tap types, and explain tapping procedures. The key points are: tapping is the process of cutting internal threads using taps, threads are spiral ridges on nuts and bolts specified by diameter and pitch, and different types of taps exist for starting, continuing, and finishing threads, including taper, plug, and bottoming taps. Safety precautions are outlined for hand tapping.