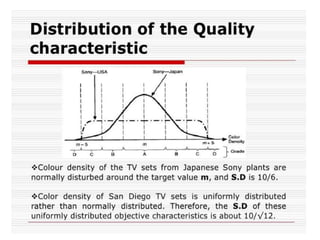

The document provides an overview of the Taguchi Method, developed by Dr. Genichi Taguchi, which focuses on improving product quality and reducing costs through robust design and experimentation. It emphasizes designing quality into products rather than relying on inspection and highlights its application across various fields, including manufacturing and environmental sciences. Despite some criticisms regarding its efficiency, the Taguchi Method has been recognized for its simplicity and effectiveness in optimizing processes and enhancing product reliability.