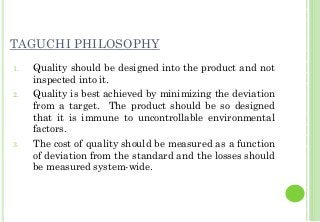

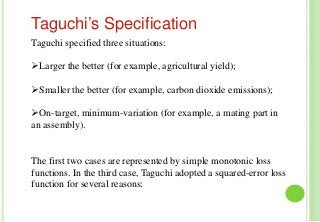

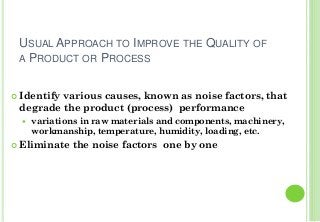

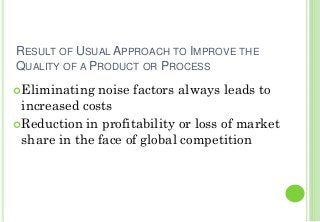

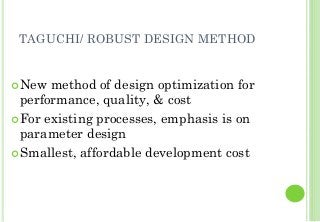

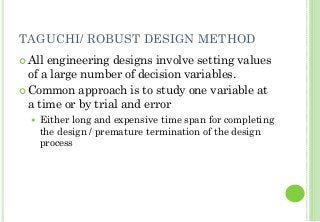

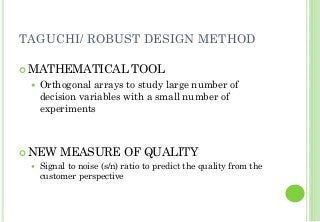

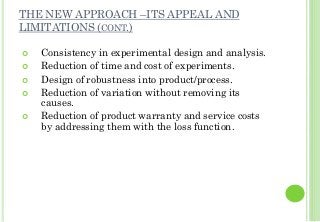

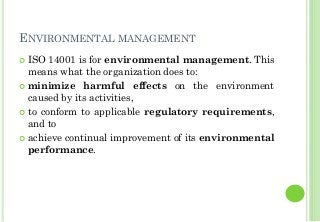

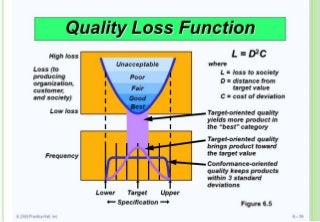

The document provides an overview of Taguchi Loss Function and Taguchi methodology. It discusses that Taguchi Loss Function is a graphical depiction developed by Genichi Taguchi to measure quality loss as the deviation from a target value. Loss is defined as a parabolic function of the deviation. Taguchi proposed measuring quality from a customer perspective using Signal to Noise Ratio. The methodology aims to design robustness using orthogonal arrays and reduce variation and costs.

![In Taguchi's view tolerance specifications are given by

engineers and not by customers; what the customer

experiences is 'loss'. This equation is true for a single

product; if 'loss' is to be calculated for multiple

products the loss function is given by

L = k[S2 + y – m)2],

where S2 is the 'variance of product size' and y is the

average product size.](https://image.slidesharecdn.com/qmstaguchi-171116133235/85/Qms-amp-taguchi-4-320.jpg?cb=1690468224)

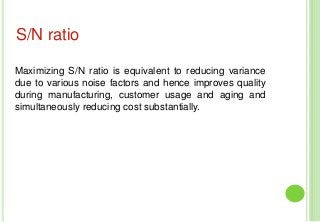

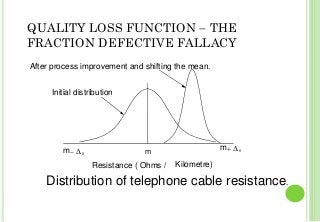

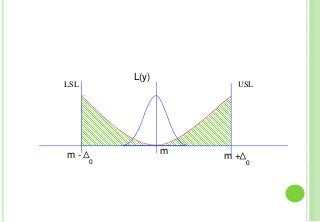

![Average quality loss

Q = k [( m - μ )2 + σ 2 ]

It consists of two components:

Shift of process average (μ) from the target

value (m)

Spread of the process (σ2)

S/N ratios are a log-modified form of Average

quality loss function](https://image.slidesharecdn.com/qmstaguchi-171116133235/85/Qms-amp-taguchi-9-320.jpg?cb=1690468224)