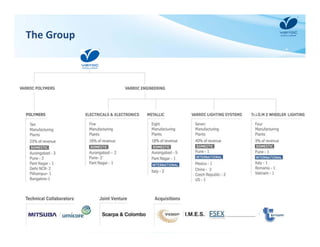

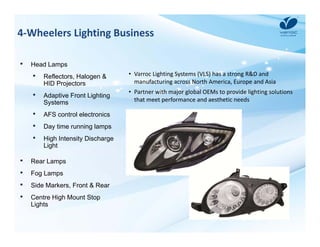

The document presents an overview of Varroc Group, a global provider of automotive components, detailing its core values, business segments, and manufacturing capabilities across polymers, electrical & electronics, and metallic businesses. It highlights the company's extensive investment in R&D and state-of-the-art facilities, along with a strong global footprint and support for major OEMs. Additionally, it describes the range of products offered, quality assurance measures, and advanced engineering infrastructure utilized in production.