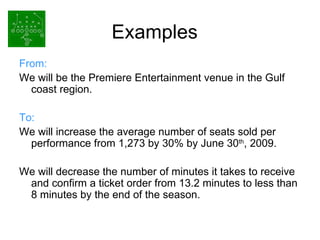

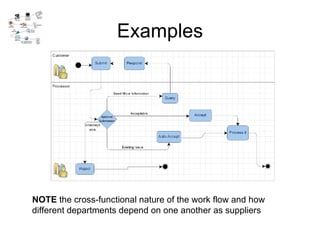

The document provides guidance on how organizations can survive economic downturns through quality improvement. It recommends listening to customer needs, establishing strategic objectives, mapping key processes, measuring performance metrics, identifying issues and their causes, prioritizing the most important problems, involving employees, eliminating waste from processes, standardizing procedures, and demonstrating the business case for quality improvement. Quality improvement is presented as a way for organizations to adapt, change, improve performance and competitiveness, and ensure long-term survival during difficult economic times.

![Thank you! Questions & Answers Mike Weekes President, Whataboutquality LLC Osprey, FL (941) 356 9434 Email: [email_address] On the web at: http://www.whataboutquality.com Blogging at: http://www.whataboutquality.wordpress.com/ ISBN 9780615272443](https://image.slidesharecdn.com/cdocumentsandsettingsabbuhdesktopharoondocssurvivethedownturnthroughquality050909-090613072939-phpapp02/85/Surviving-Downturn-Through-Quality-24-320.jpg)