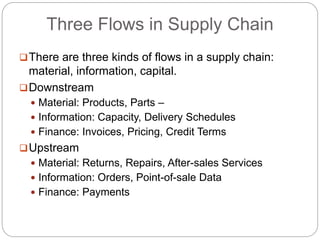

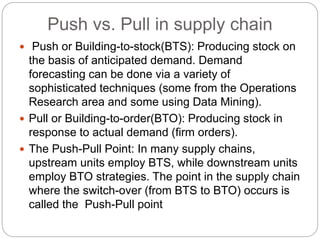

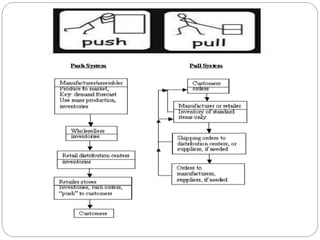

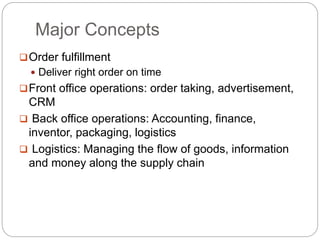

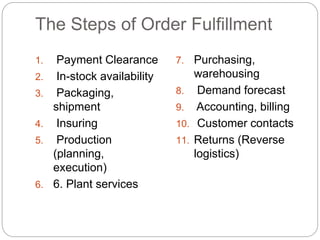

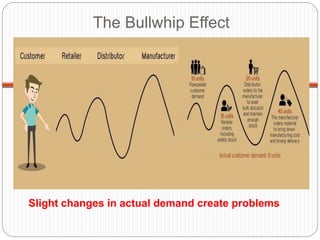

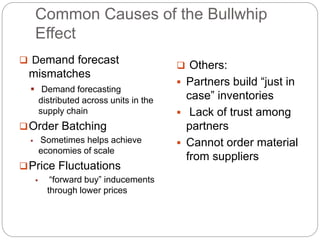

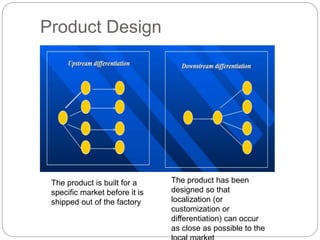

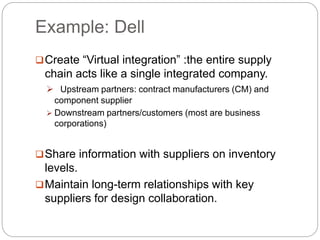

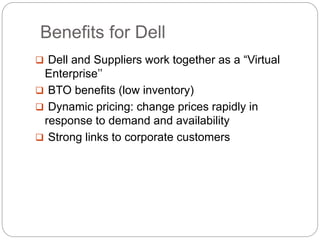

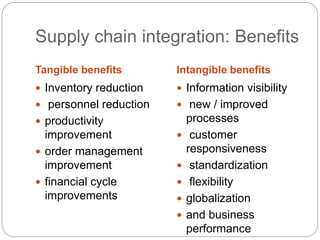

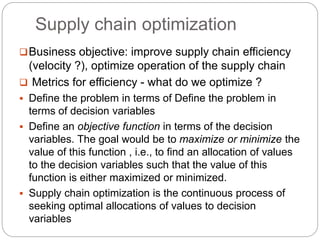

A supply chain encompasses all activities related to the flow and transformation of goods from raw materials to end users, involving material, information, and capital flows. It includes upstream and downstream operations, decision-making between push (building-to-stock) and pull (building-to-order) strategies, and requires effective logistics and integration of partners. Key benefits of supply chain management include reduced uncertainty, improved inventory levels, and enhanced customer service, while challenges involve complex networks and the bullwhip effect due to demand forecasting and coordination issues.