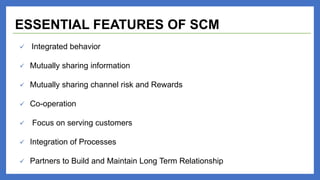

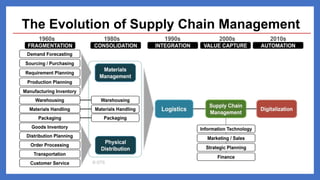

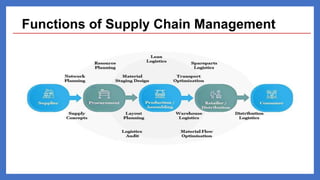

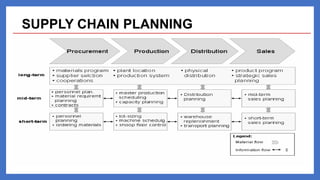

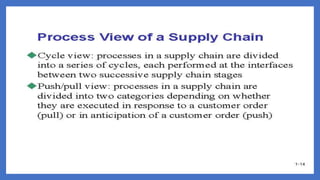

This document discusses supply chain management. It defines SCM and its objectives. It describes the evolution of SCM from material management to integrated supply chain management. It outlines the functions, decision phases, and strategic fit of SCM. It also discusses drivers and enablers of SCM performance, including qualitative and quantitative measures.