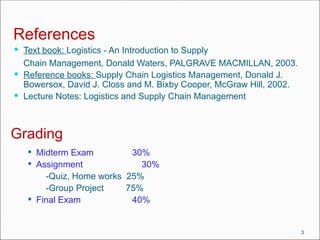

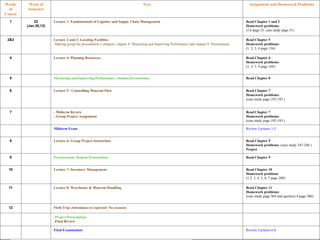

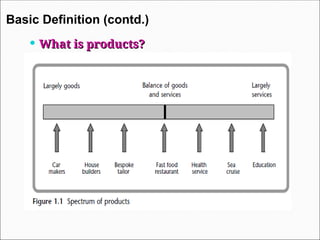

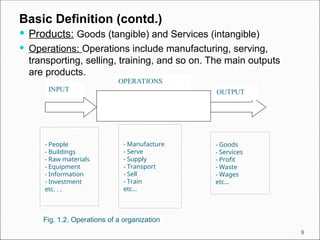

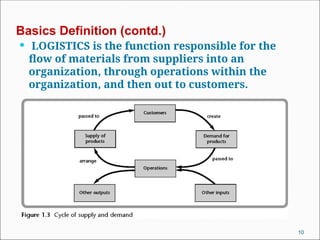

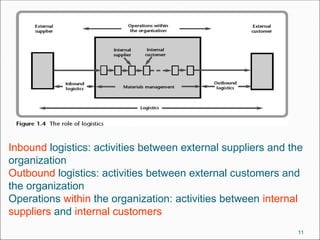

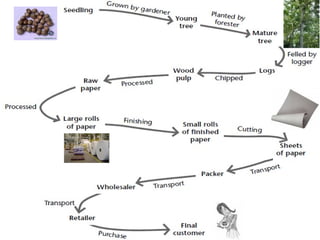

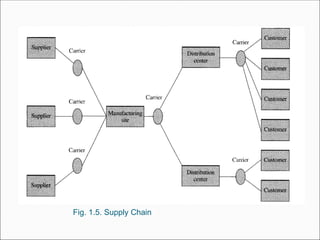

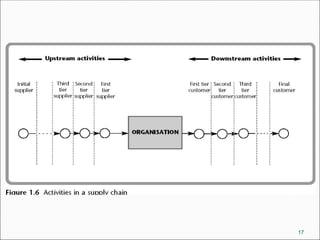

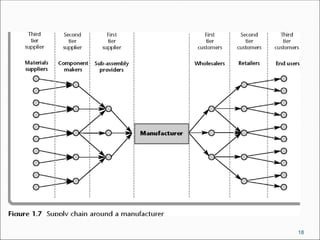

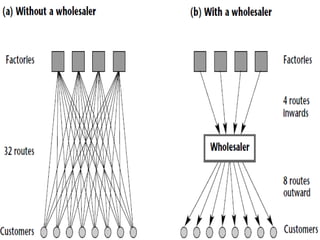

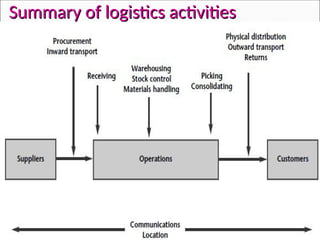

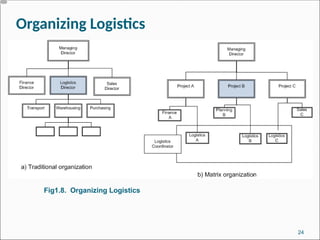

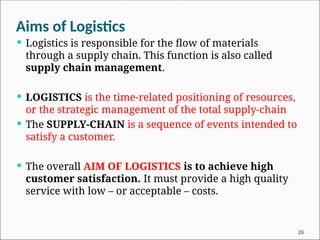

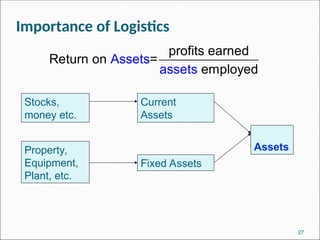

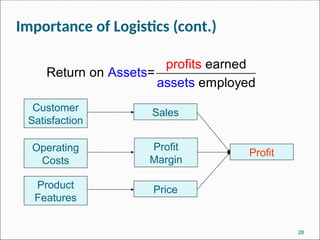

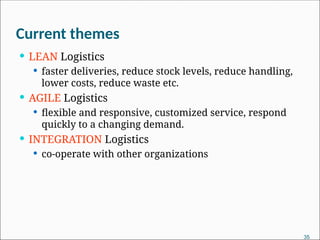

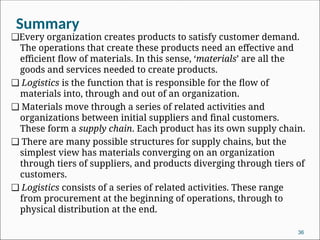

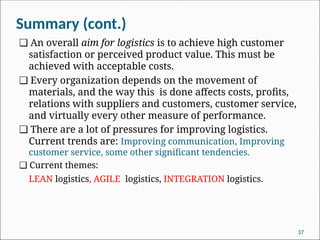

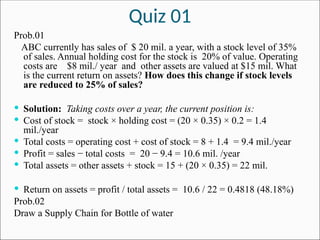

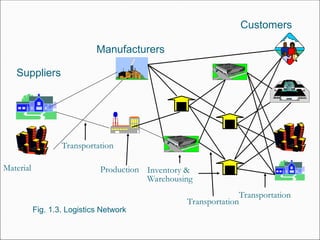

The document outlines the logistics and supply chain management course objectives, grading structure, schedule, and key learning points. It emphasizes understanding logistics definitions, supply chain roles, and efficient material flow management, as well as the importance of customer satisfaction in logistics. The course also includes a group project, various homework assignments, and references to textbooks and additional materials.