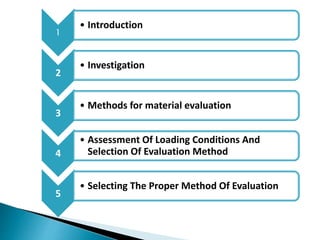

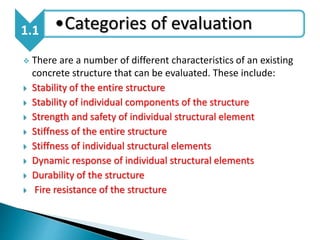

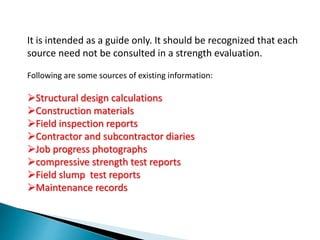

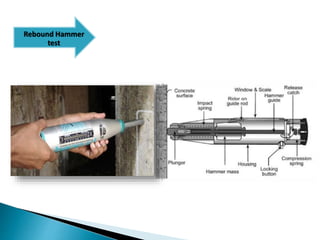

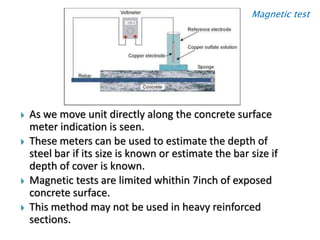

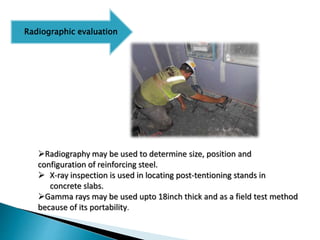

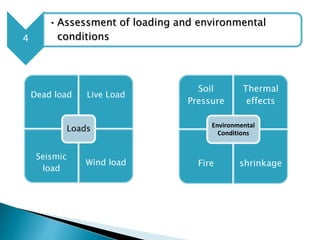

This document discusses methods for evaluating the strength of existing concrete structures. It describes preliminary investigation which includes reviewing existing information and conducting a condition survey. Various in-place nondestructive testing methods are discussed for evaluating concrete properties, such as rebound hammer, pulse velocity, and sounding tests. Reinforcing steel can be located using magnetic or radiographic tests. The document also covers assessing loading conditions and selecting evaluation methods, such as using analysis alone, analysis with in-place load testing, or analysis with small-scale model testing.