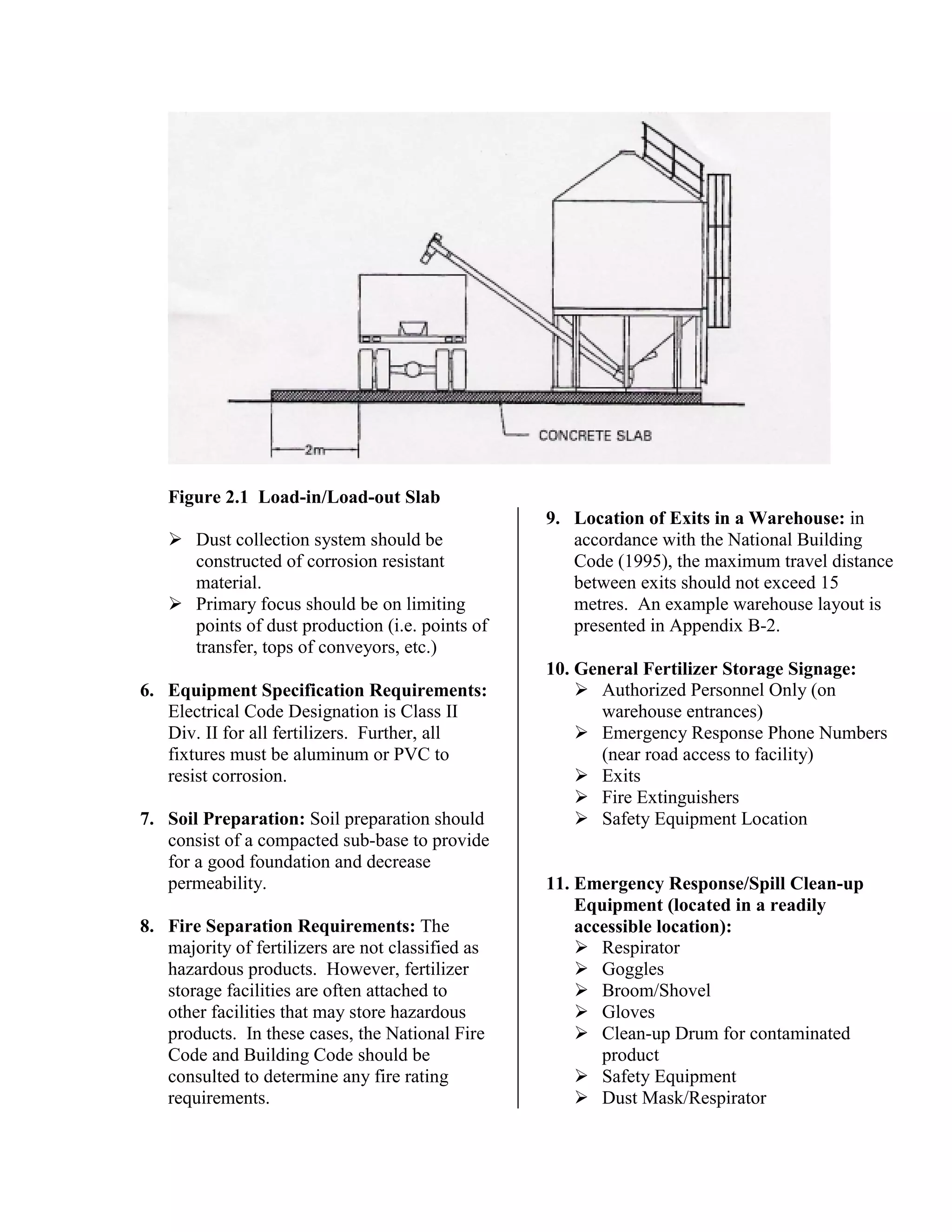

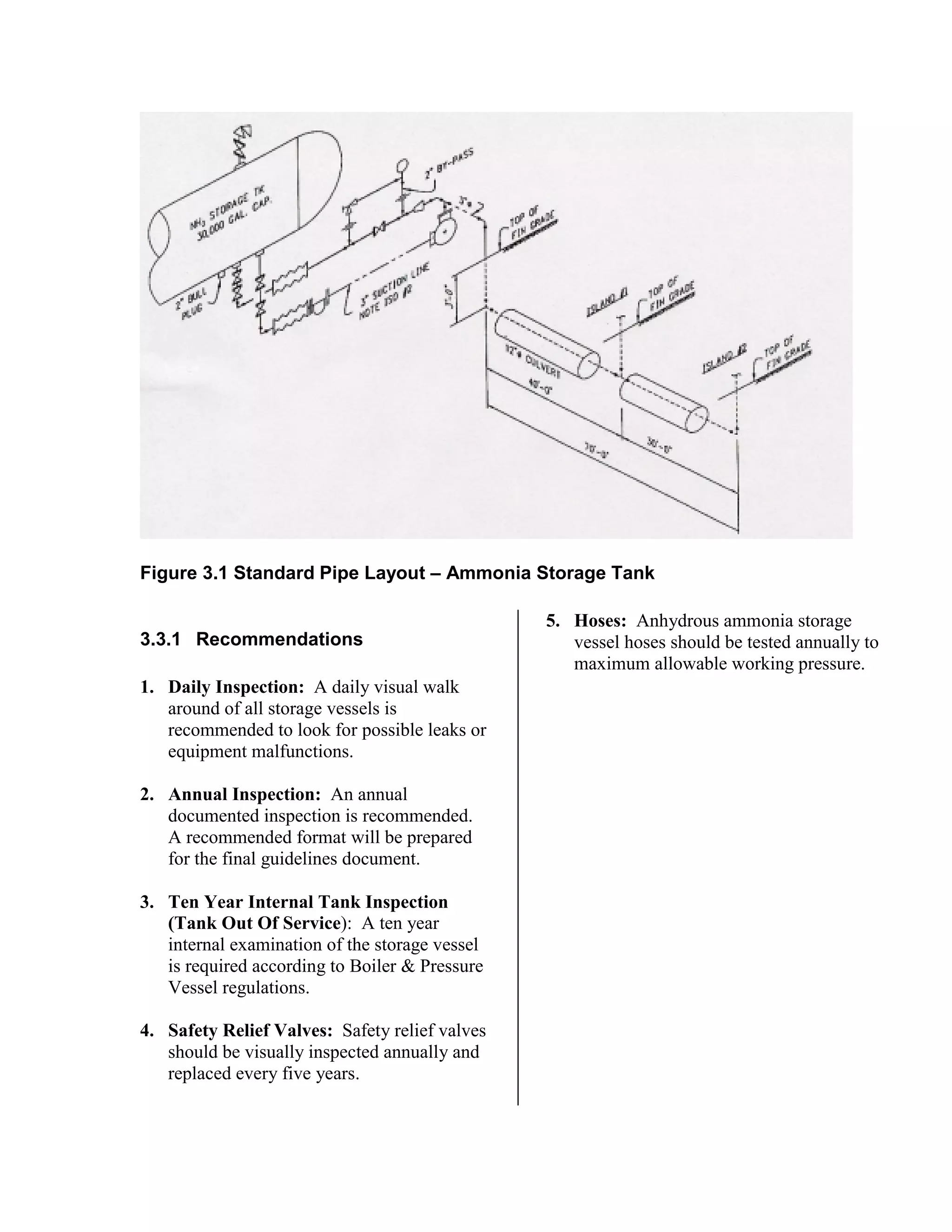

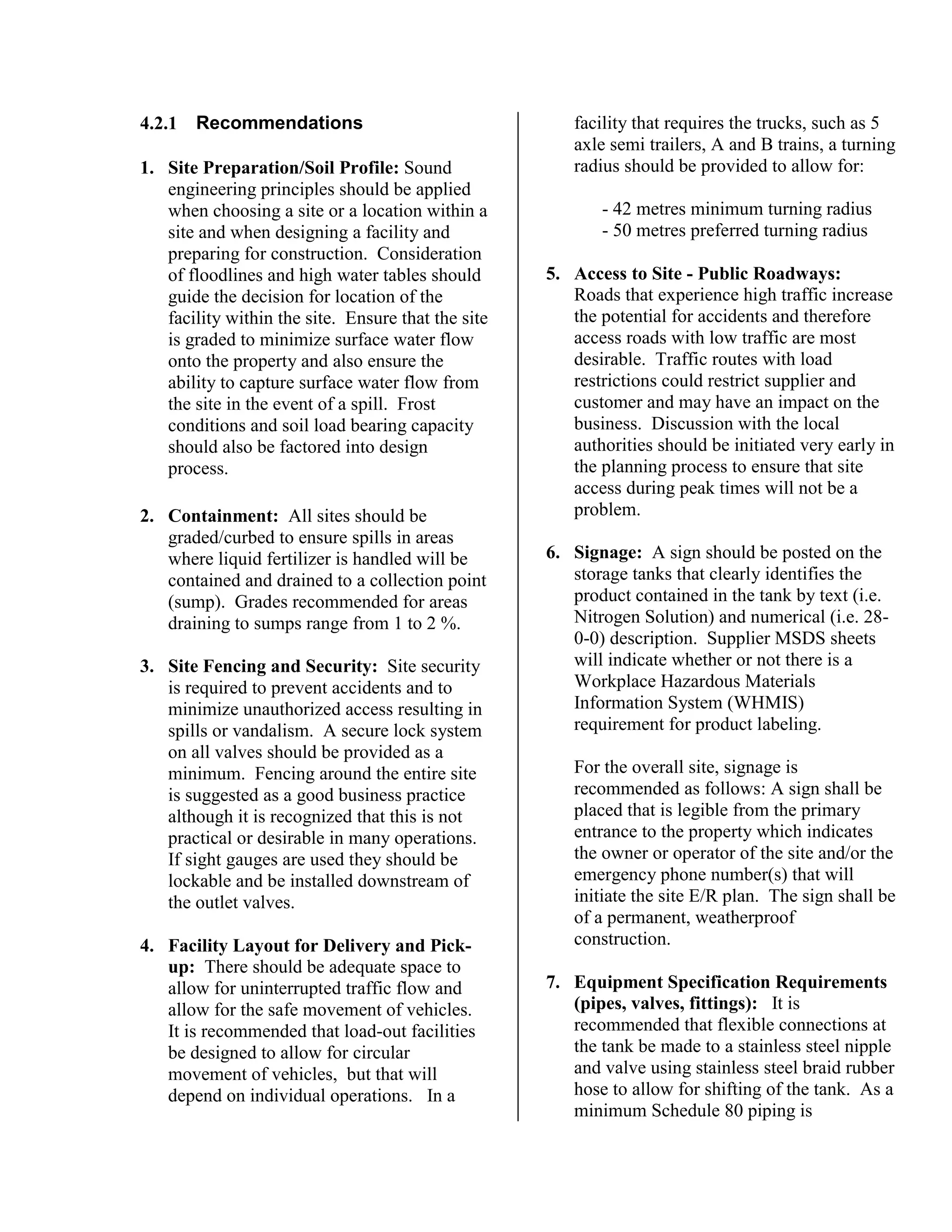

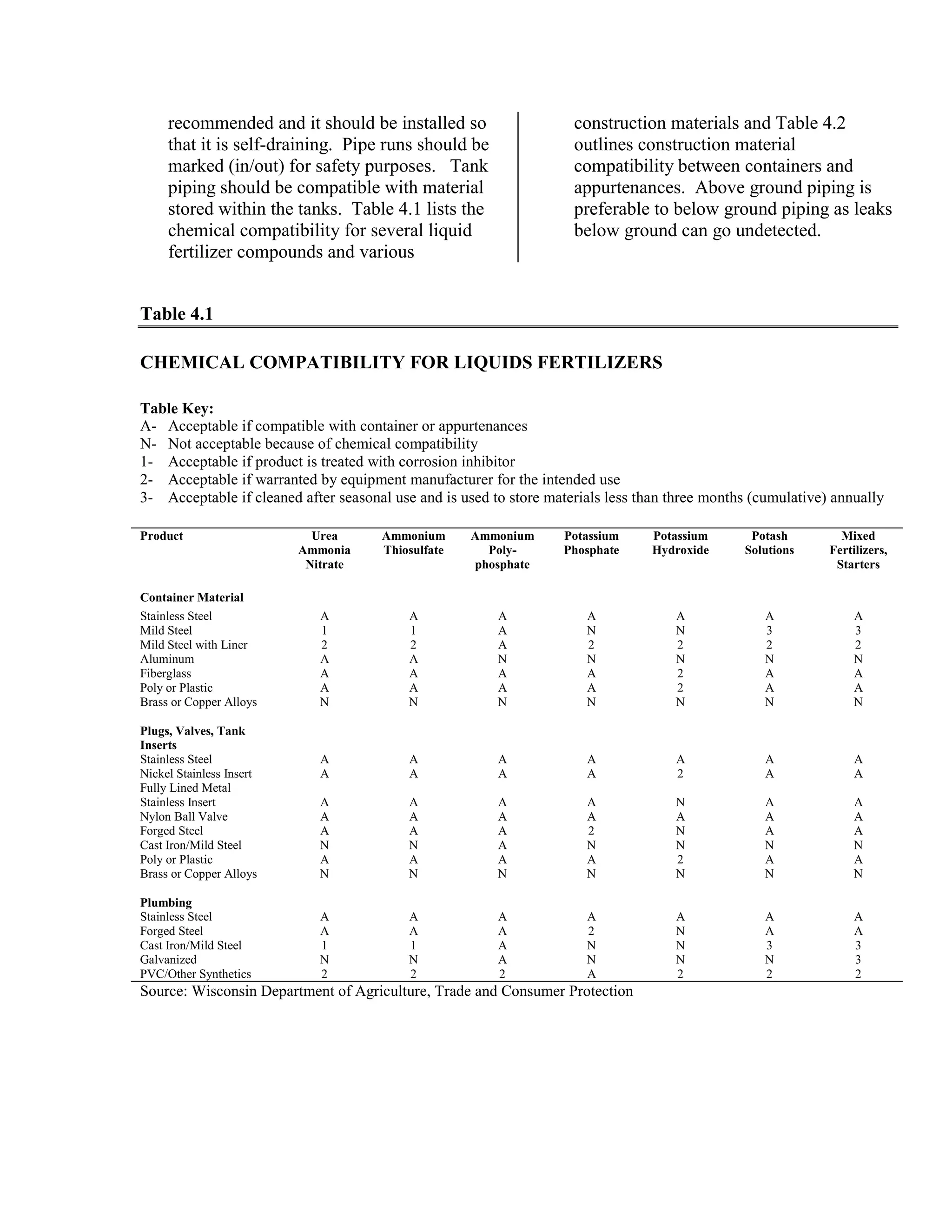

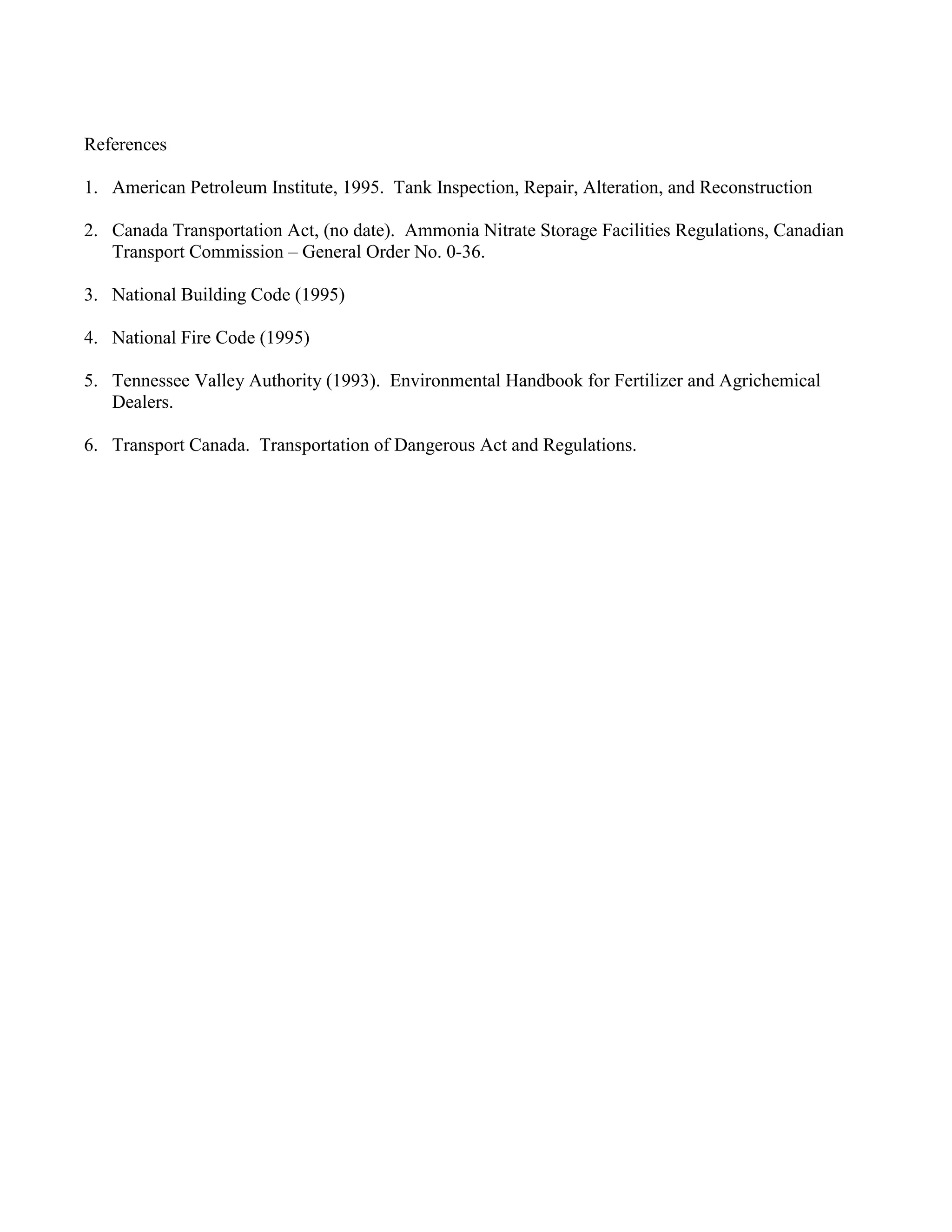

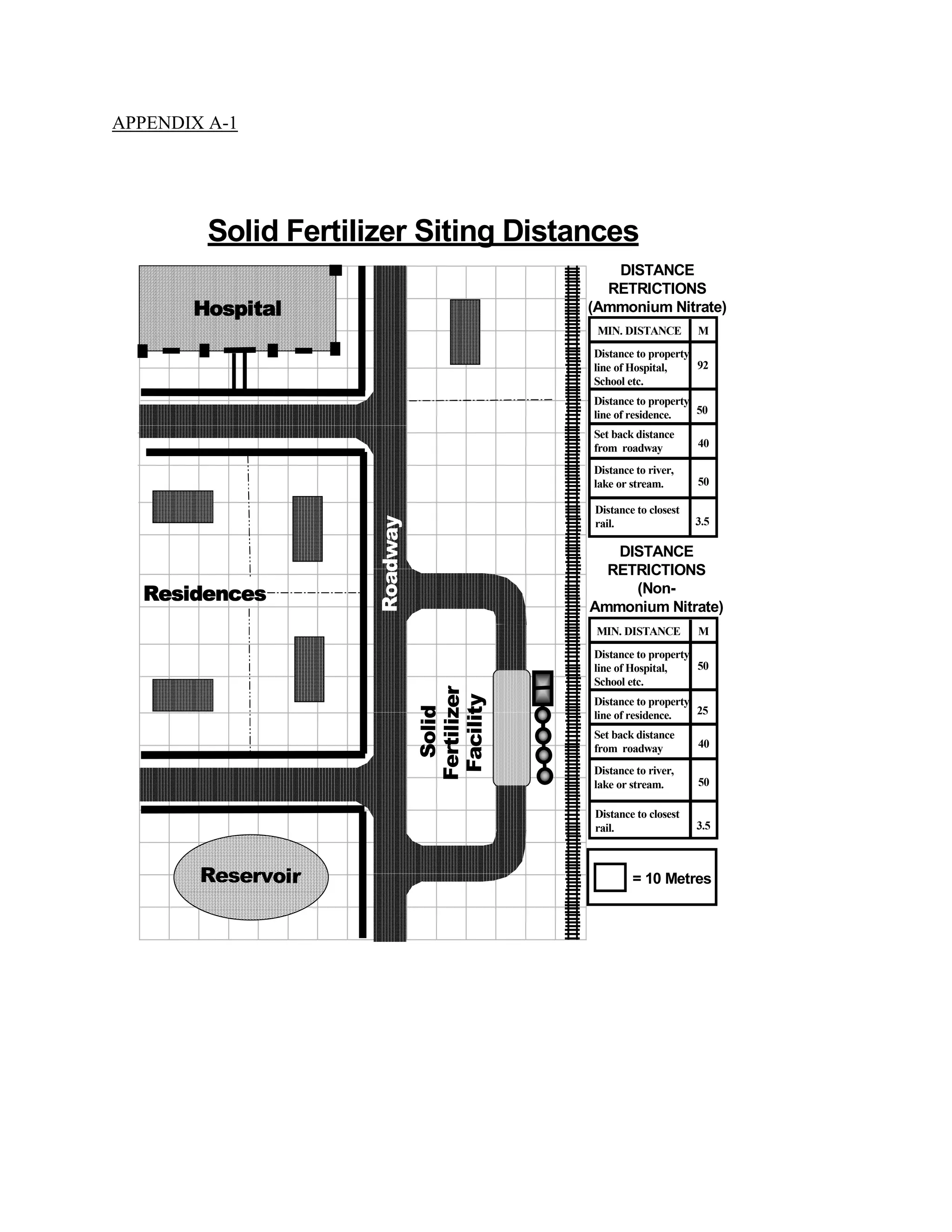

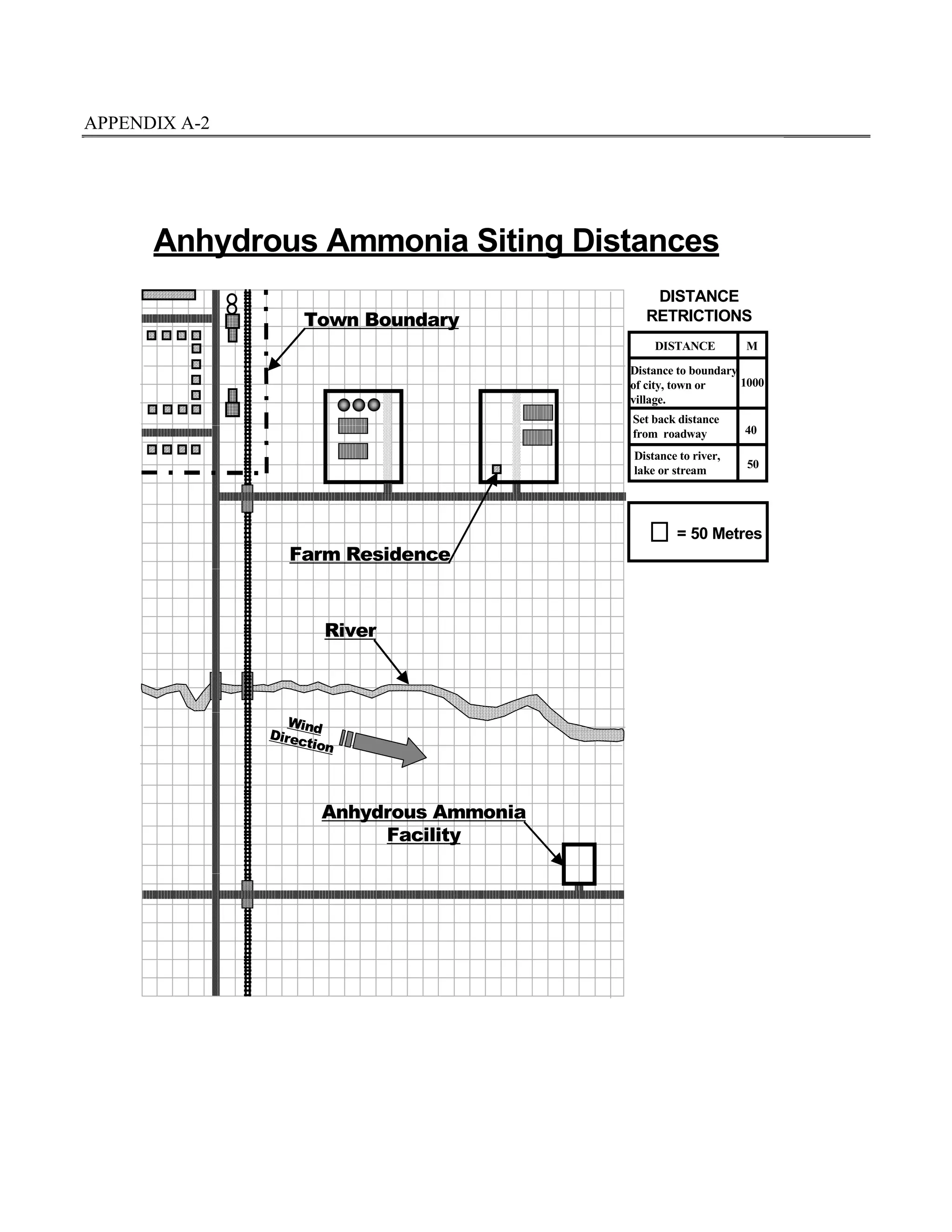

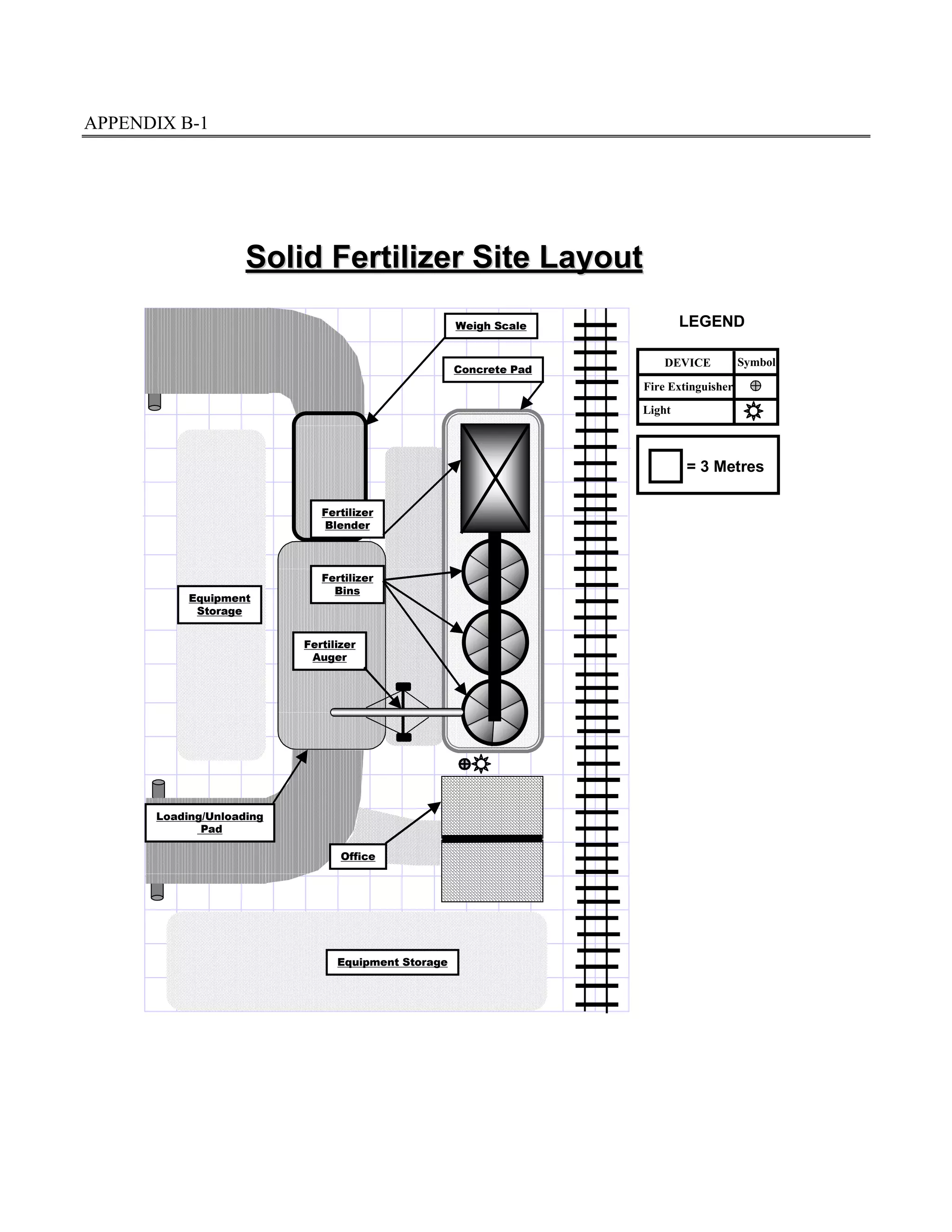

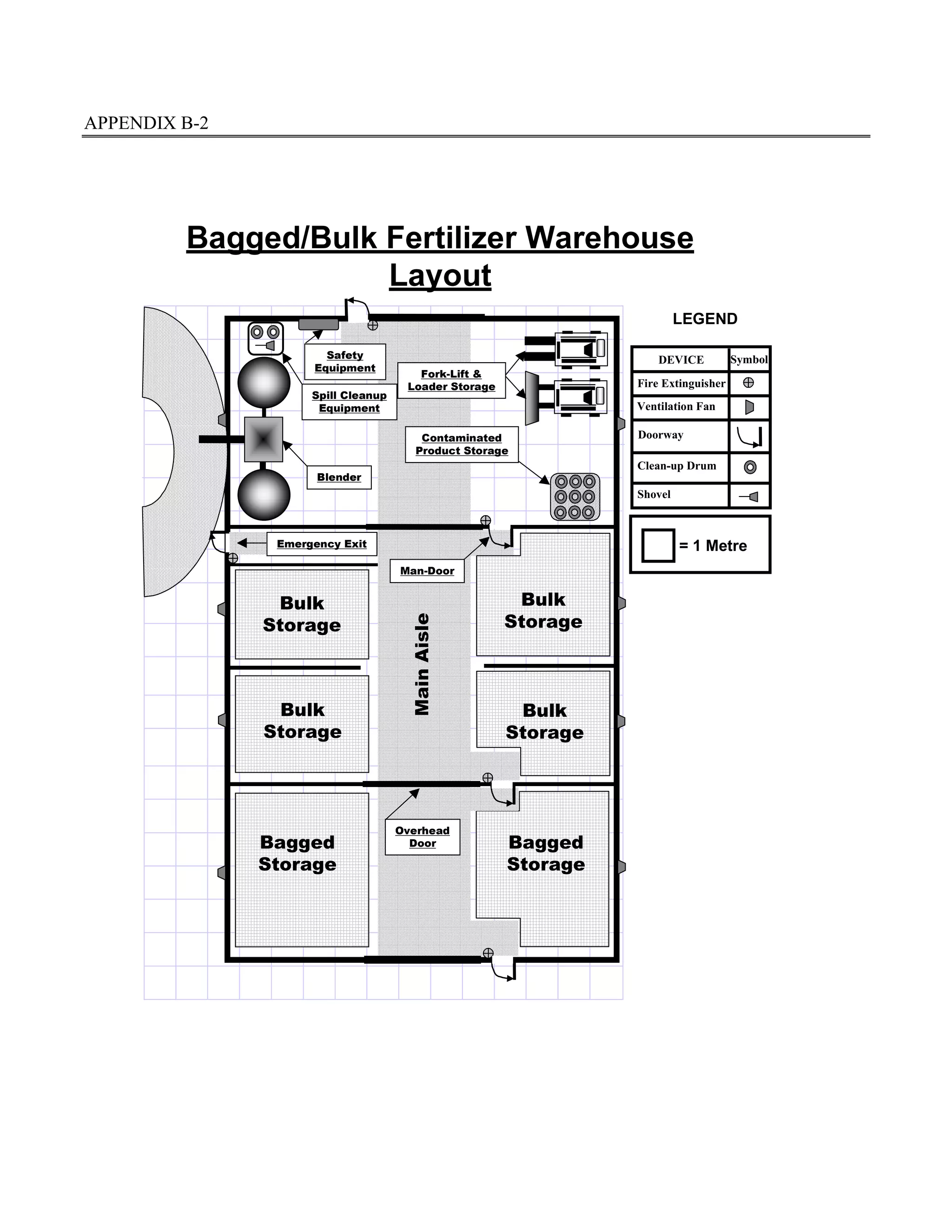

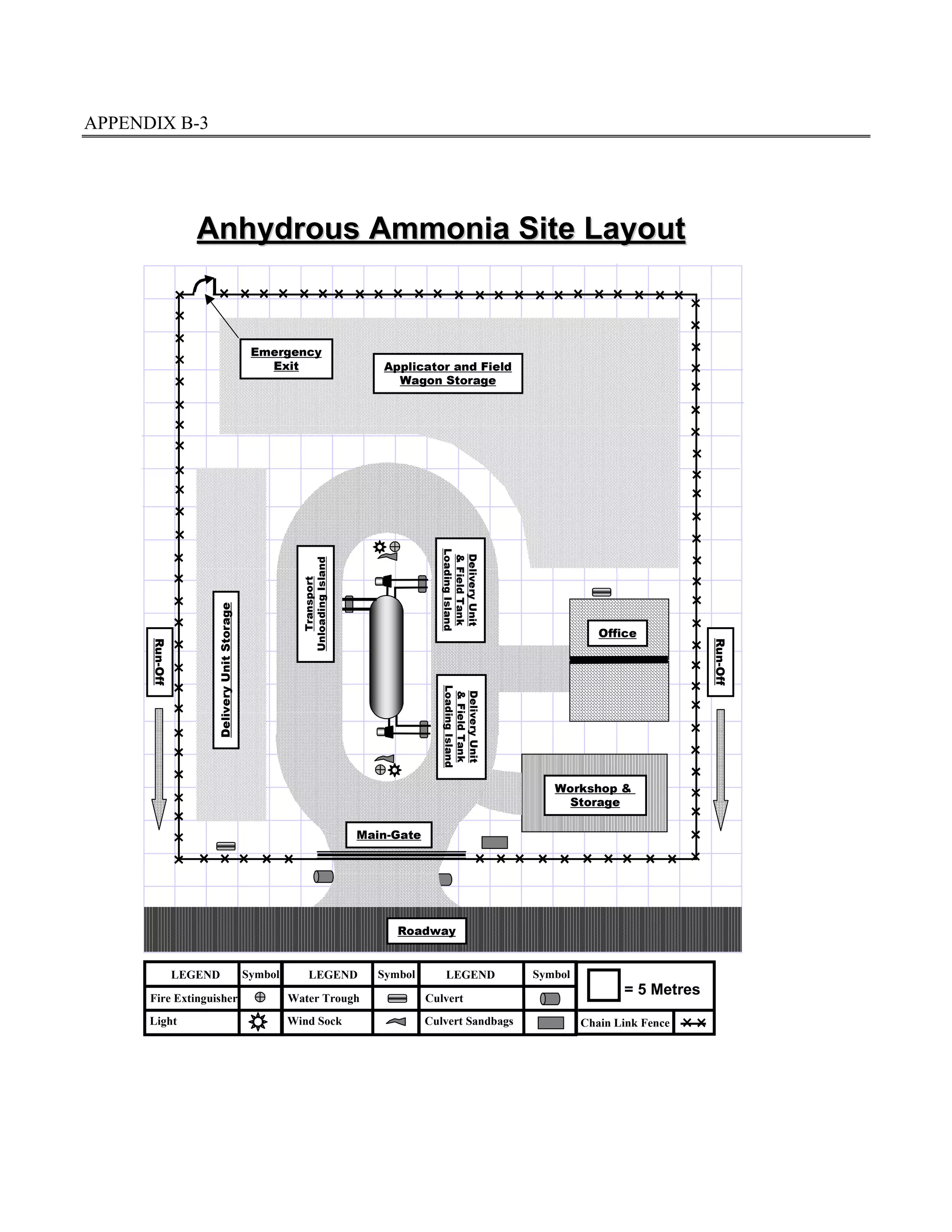

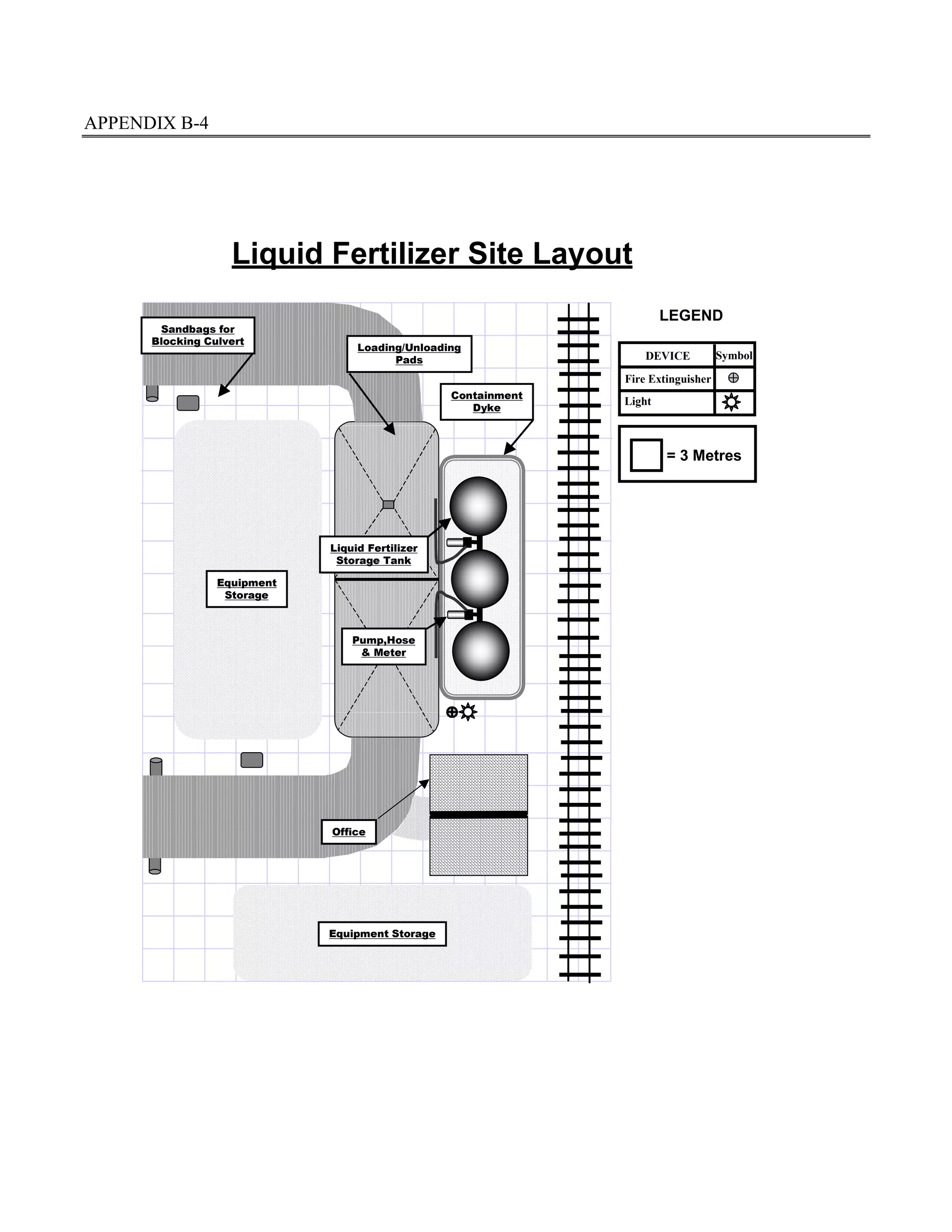

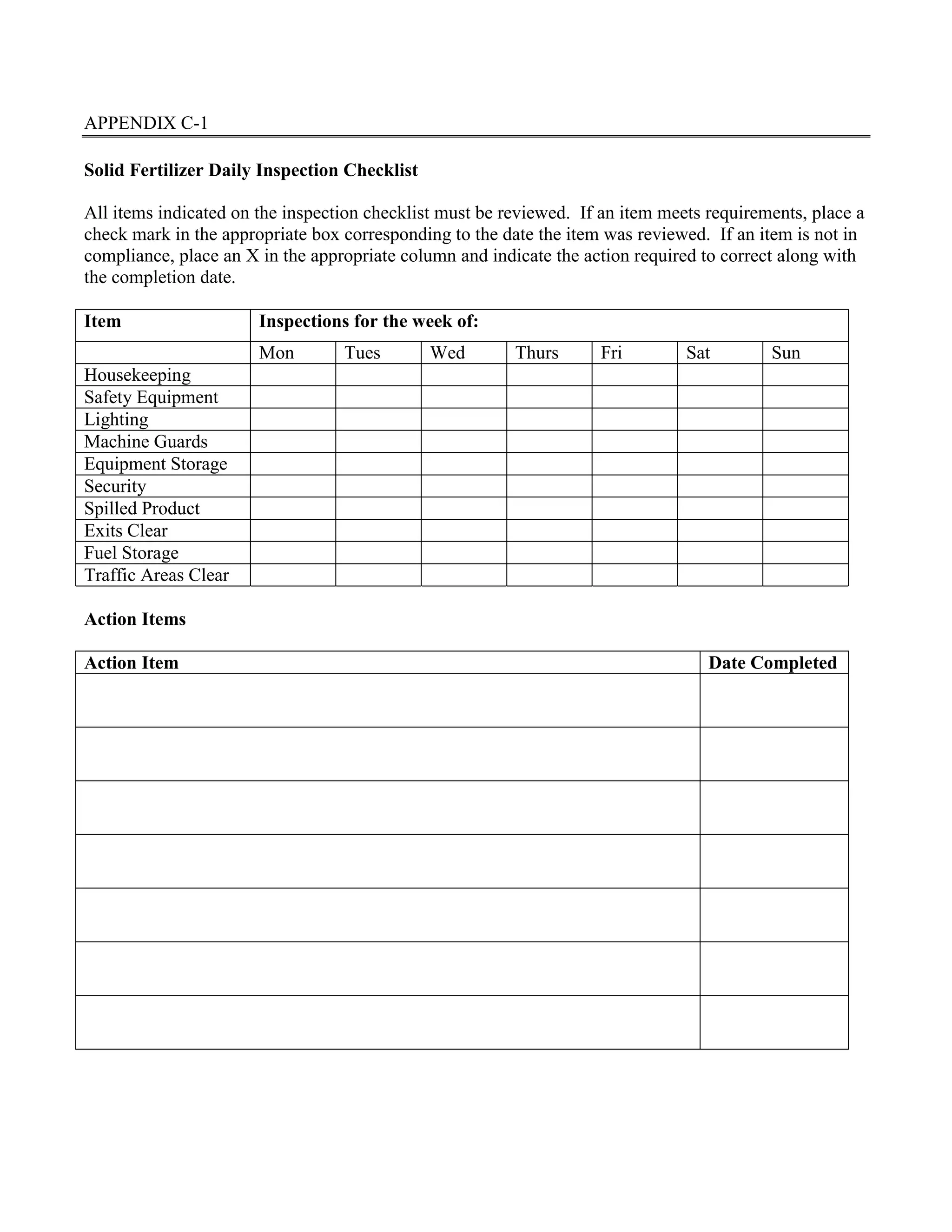

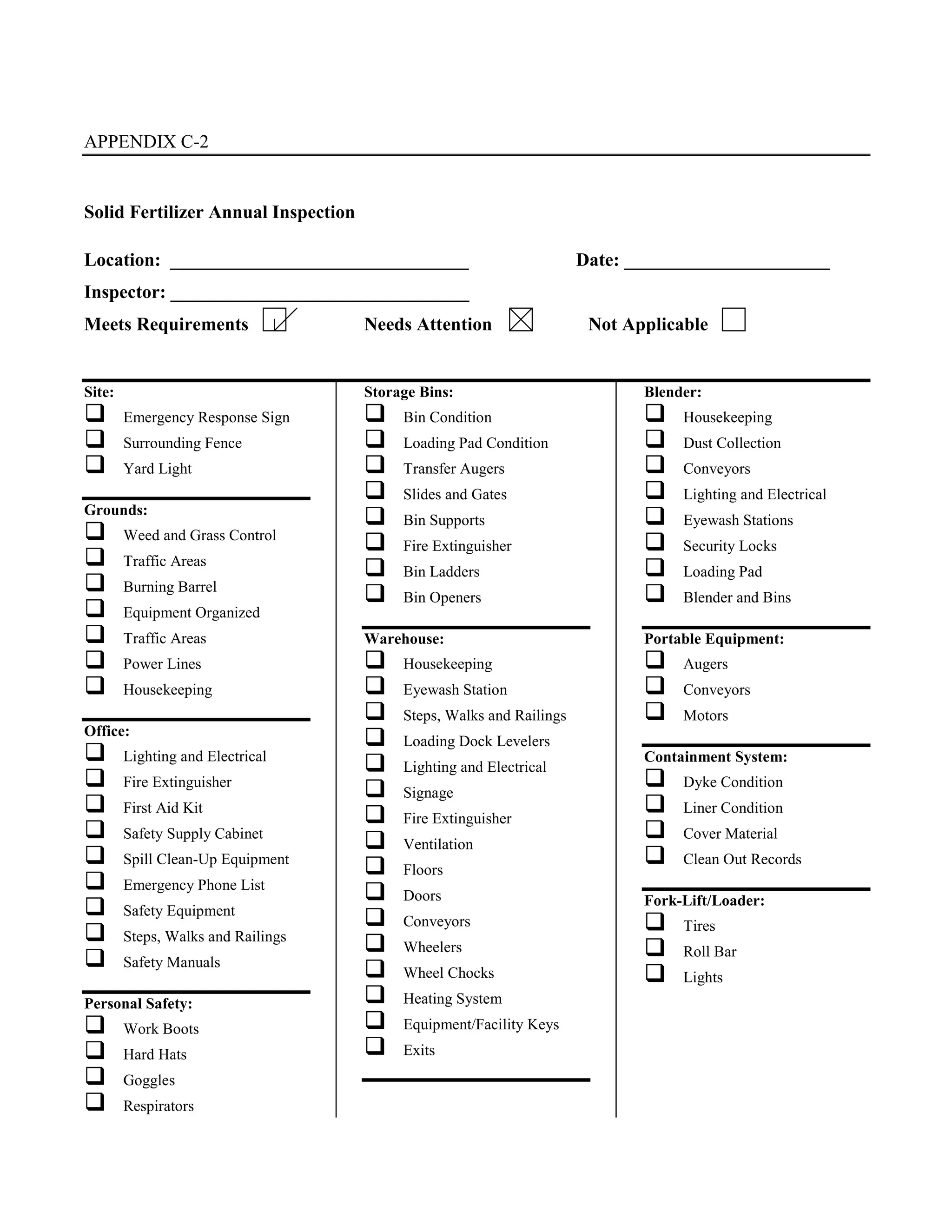

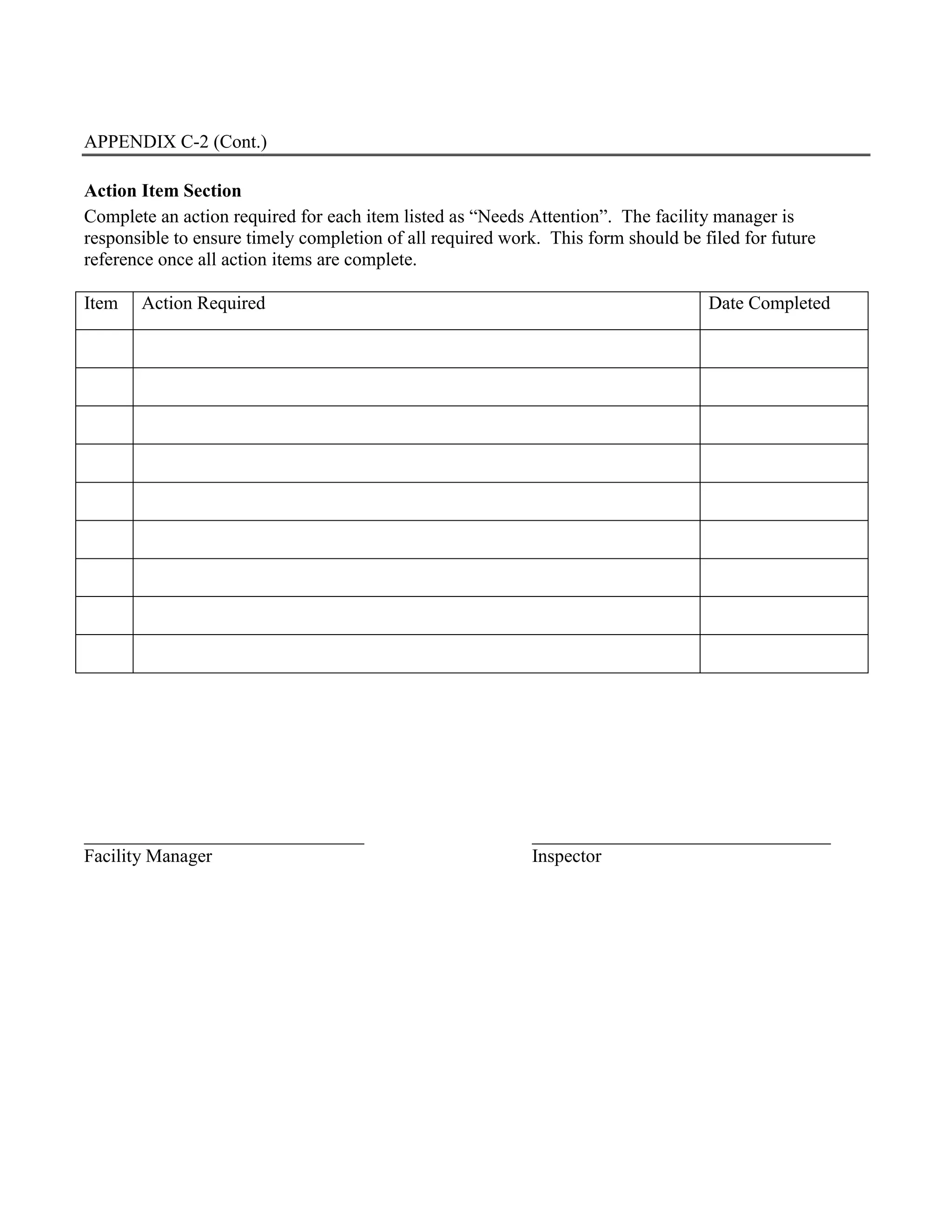

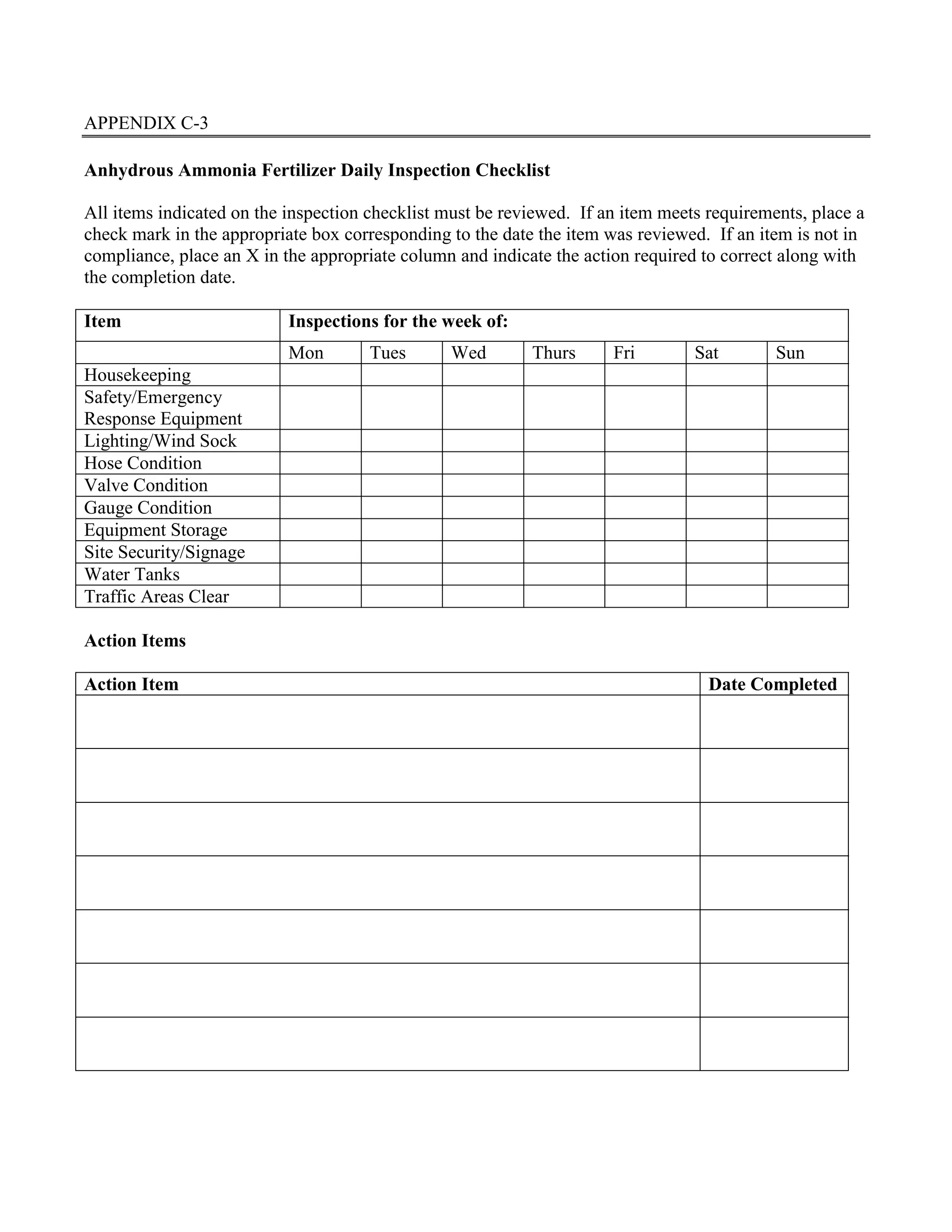

This document contains guidelines for the storage and handling of solid, anhydrous ammonia, and liquid fertilizers in Canada. For solid fertilizers, it recommends siting distances of at least 25 meters from property lines and 50 meters from water bodies. It also provides recommendations for facility design, equipment, inspections, and emergency response. For anhydrous ammonia, it establishes siting distance recommendations and lists additional emergency response programs required for existing facilities within 1 km of communities. The guidelines aim to minimize safety and environmental risks based on a risk assessment of the fertilizer industry.