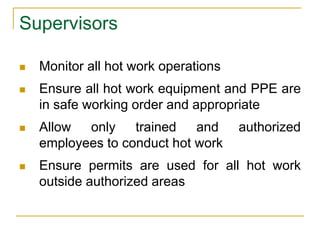

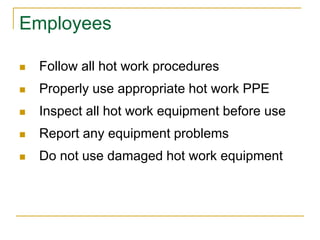

This document outlines hot work procedures and fire safety measures for cutting and welding. It specifies that combustibles must be relocated at least 35 feet from work sites or protected from sparks. Fire watches are required when combustibles cannot be relocated. Cutting and welding are prohibited in certain areas and conditions to prevent fires. Suitable fire extinguishers must be provided and hot work areas must be monitored by supervisors to ensure safety procedures are followed.