Embed presentation

Download to read offline

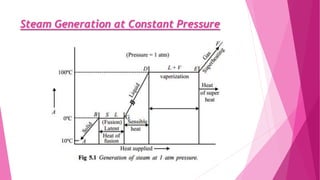

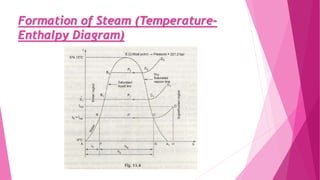

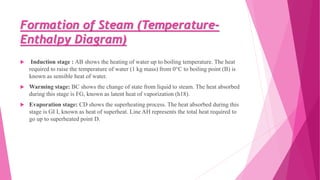

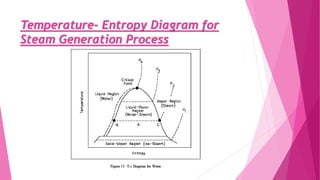

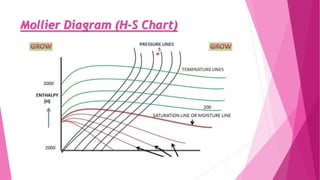

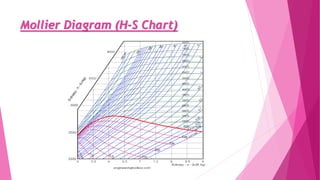

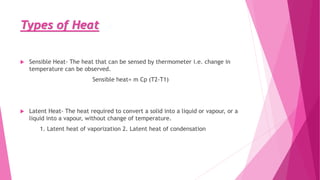

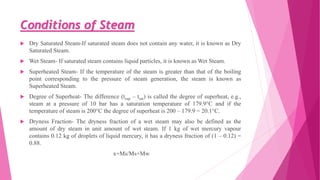

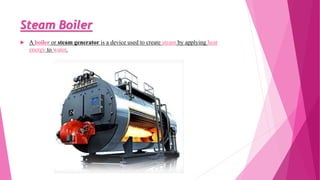

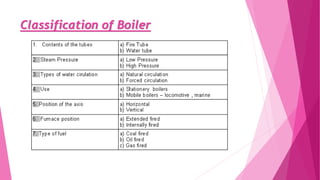

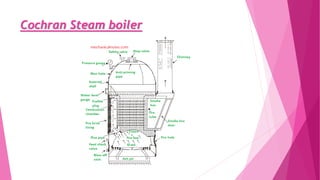

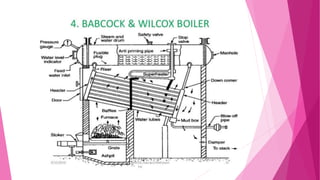

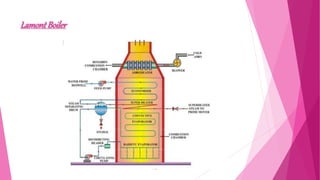

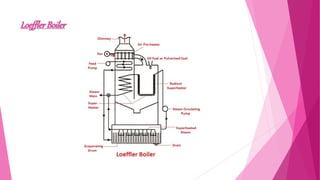

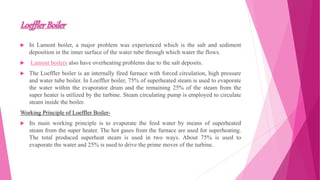

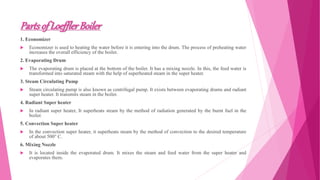

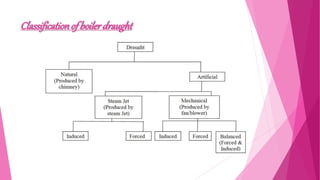

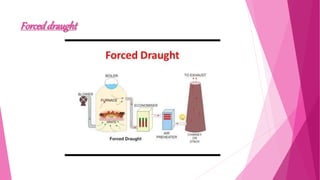

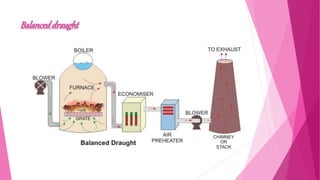

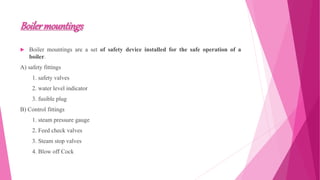

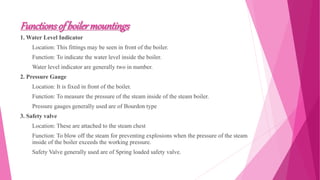

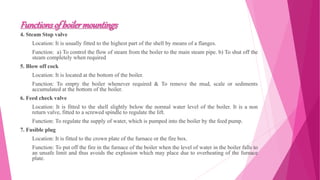

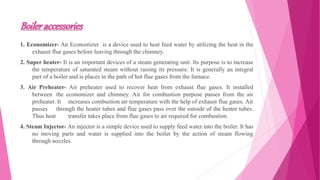

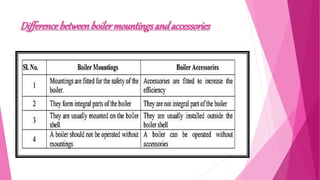

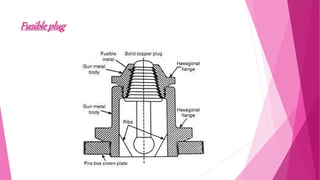

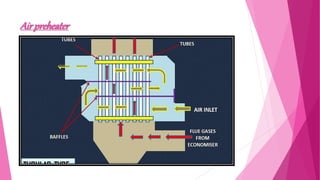

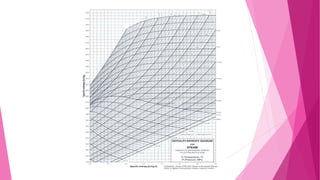

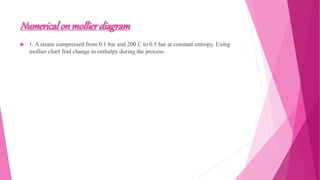

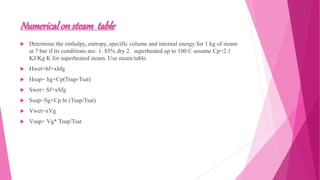

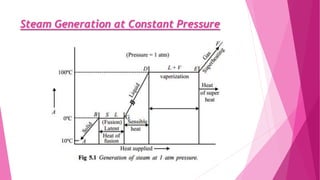

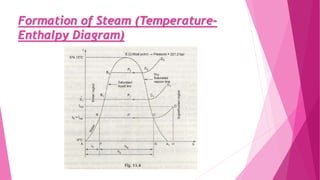

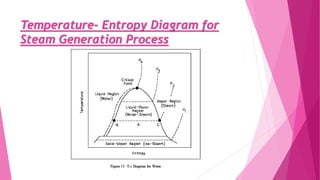

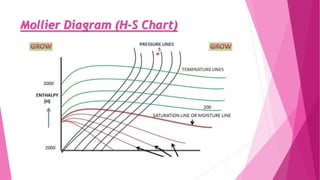

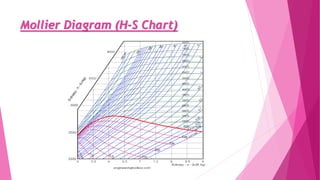

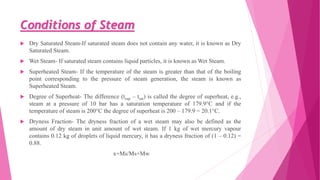

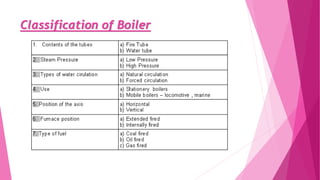

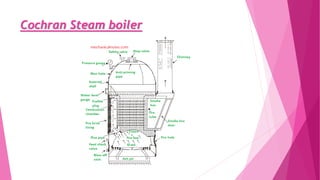

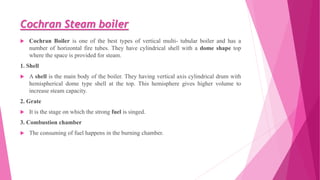

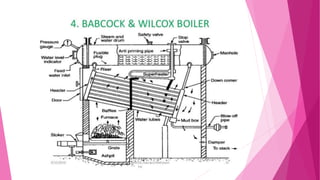

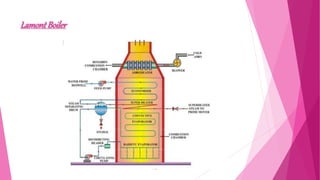

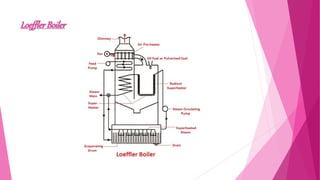

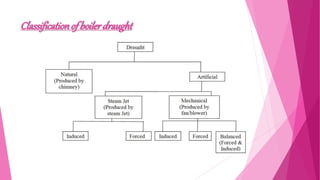

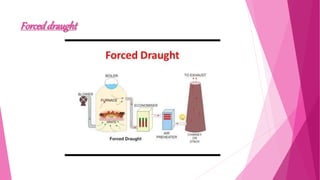

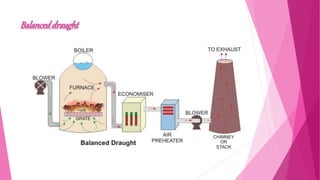

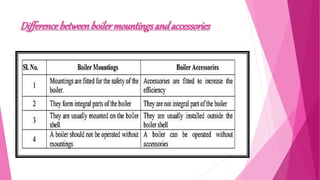

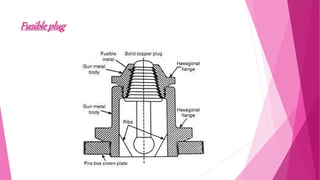

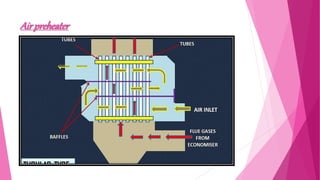

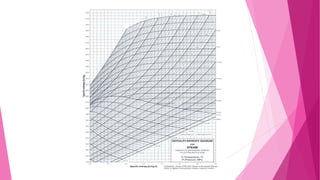

This document discusses steam and steam boilers. It defines steam and its common applications like process heating, power generation, and drying. It explains the steam generation process using temperature-enthalpy and temperature-entropy diagrams. Different types of heat involved in steam generation are defined. Conditions of steam like dry saturated, wet, and superheated steam are explained. Different types of boilers like Cochran, Lamont, and Loeffler boilers are described along with their working principles. Boiler mountings, accessories, draught systems, and numerical problems involving steam tables and Mollier diagrams are covered.