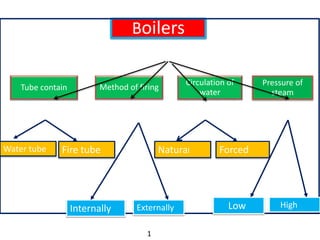

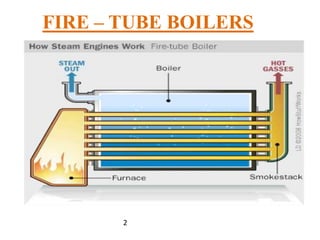

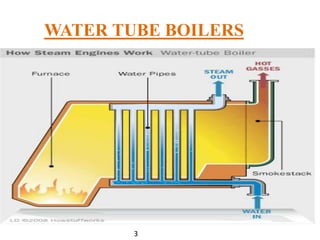

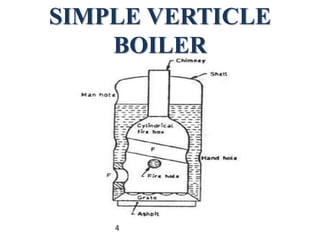

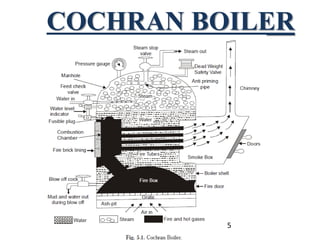

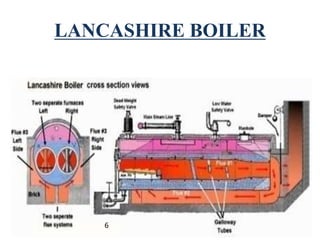

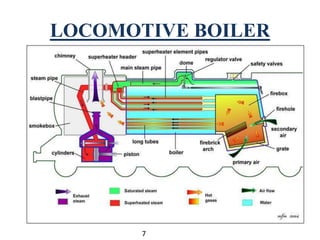

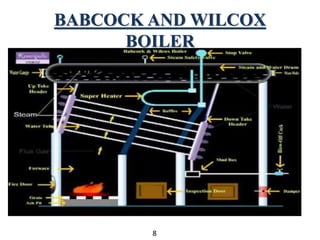

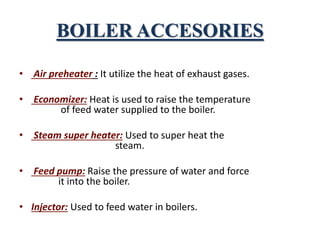

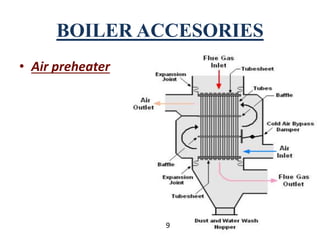

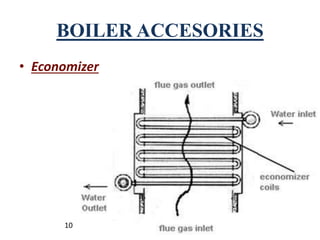

The document discusses different types of steam boilers. It describes the key components and functions of a boiler, including that a boiler is a closed vessel that transfers heat from fuel combustion to generate steam. It classifies boilers based on factors like tube layout (fire tube vs water tube), furnace position, and circulation method. Specific boiler types are outlined like the Lancashire boiler and locomotive boiler. Boiler properties, safety features, efficiency factors and selection considerations are also summarized. Diagrams are included to illustrate different boiler components and designs.