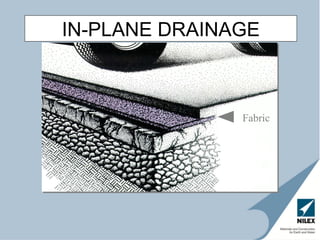

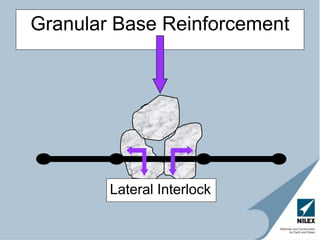

Nilex Inc. provides geosynthetic materials and solutions for roads, retaining walls, erosion control, drainage, containment, and ground modification. It has office locations across western Canada. The document discusses Nilex's product applications and geosynthetic functions such as separation, filtration, drainage, subgrade improvement, and granular base reinforcement. It also provides examples of Nilex's geosynthetic solutions used in infrastructure projects.