When textile fibers absorb water, they swell both transversely and axially. Transverse swelling causes an increase in the fiber's diameter, while axial swelling causes an increase in length. The degree of swelling is measured as the percentage increase in diameter, area, length, or volume. Different textile fibers exhibit different levels of swelling depending on their molecular structure, with natural fibers like cotton and wool typically swelling more than synthetic fibers like nylon. The swelling properties of fibers impact their dye absorption, water resistance, dimensional stability, and other material properties.

![ΔL

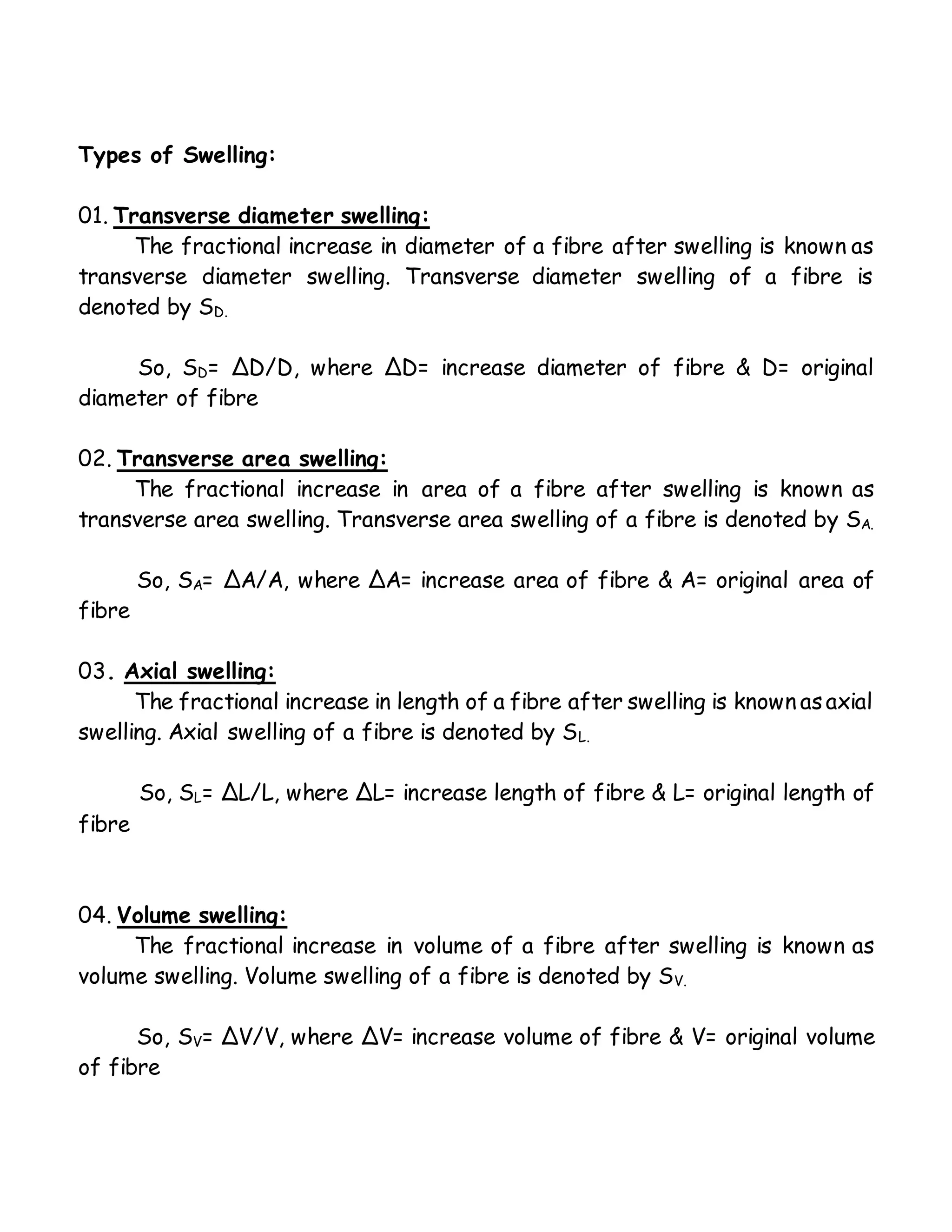

Relationship among volume swelling (SV), transverse area swelling (SA) &

Axial swelling (SL): Sv = SA + SL + SA. SL

Relationship between transverse diameter swelling (SD) & transverse area

swelling (SA): SA = 2.SD + SD

2

[Ref: Physical Properties of Textile Fibres- by W.E. Morton

Chapter-11,Swelling]

Swelling (%) of different fibres:

Fibre

Transverse

dia.

swelling %

(SD)

Transverse

area swelling %

(SA)

Axial

swelling

% (SL)

Volume

swelling

% (SV)

Cotton 20 40 - -

Flax 20 47 0.1 -

Jute 20 40 - -

Viscose

rayon

35 67 3.7 119

Wool 14.8 25 - 37

Silk 16.5 19 1.6 30

Nylon 1.9 1.6 2.7 8.1

A

A+ΔA

D

L

D+ΔD

V V+ΔV

Swollen fibre

Original fibre

D+ΔD](https://image.slidesharecdn.com/swellingpropertiesoftextilefibers-210811142853/75/Swelling-Properties-of-Textile-Fibers-3-2048.jpg)