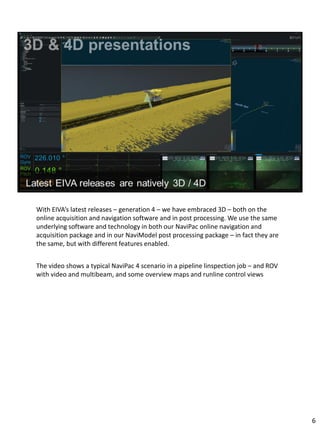

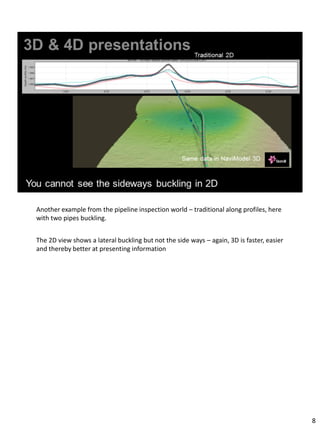

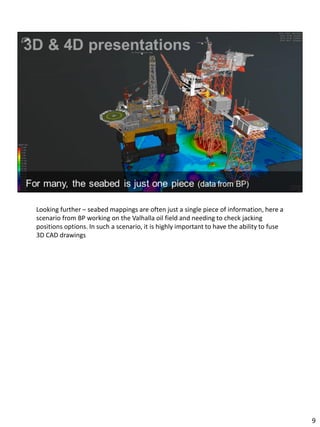

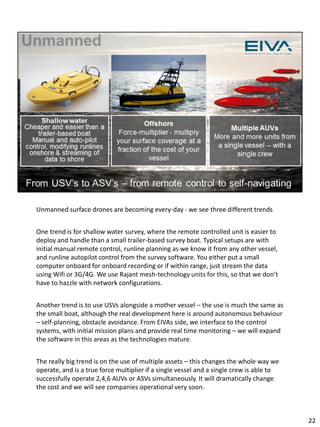

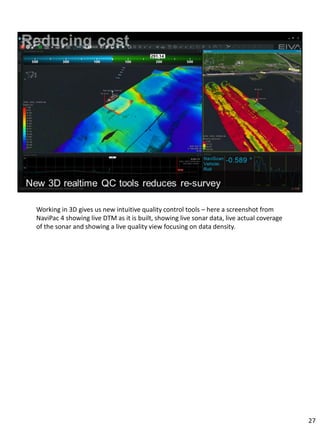

This document provides an overview of trends in the hydrographic surveying industry from a presentation given by EIVA, a company that provides hydrographic software solutions. It discusses the adoption of 3D modeling and data visualization, increasing data sizes from new sensor technologies, a focus on cost reduction through automation and optimization of workflows. Upcoming developments mentioned include improvements to automated data cleaning algorithms, point cloud processing tools, and more advanced autonomous mission planning capabilities. The presentation concludes by offering a free software package to hydrographic offices and noting EIVA's support of educational uses of their software.