The document presents a smart vehicle and smart signboard system aimed at controlling the speed of two-wheelers to prevent accidents at busy junctions. It outlines a proposed system consisting of a zone transmitter and a receiver unit that communicates wirelessly using Zigbee technology, allowing for automatic speed regulation based on predefined zone limits. The system integrates a microcontroller for monitoring vehicle speed and issuing alerts, thereby enhancing road safety.

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

ISSN 0976 – 6359(Online), Volume 6, Issue

signboards and there is a chance for accident

can control the speed of vehicles. Here we are designing a speed control system for vehicles which

can intimate the driver about the zones and limit speed of the vehicle automa

This paper develops an intelligent speed adaptation, which can monitor the vehicle speed and

implements an action when the vehicle is detected to be exceeding the speed displayed in the speed

display (sign) boards [2]. The speed display boards

protocol. The driver should take great attention on the speed of the vehicle especially when driving

through busy junctions, railway crossings, school and college zones etc[3].The citizens are ought to

obey the speed enforcement rules in order to avoid the accidents, any violation in this are considered

as a greater offence. Traffic Police are authorized to check every vehicle and take actions against the

violation [4]. But it may not be practically possible alwa

a way that the vehicle speed is automatically controlled through over a wireless communication

[5][6].

2. EXISTING SYSTEM

The figure 1 shows electrical circuit demonstration for the working of a two wheeler. It has

an excitor coil which is excited by flywheel of two

voltage to the circuit. It has also a pulse rotor. It has one magnet

trigger circuit of SCR. The rotation of which depends on the requirement of speed.

Fig.1.

There is an ignition stop switch when it is closed and charges the capacitor .There is a

d1 through which the capacitor is charged and it is connected to primary of step up transformer.

There will be an SCR, in a solid state device which when triggered discharges the capacitor and

produces ignition .There will be an ignition coil and sp

fuel in the engine.

3. PROPOSED SYSTEM

The proposed system consists

connected, one in the speed display board and the other inside the vehicle. The module at display

Board includes, Microcontroller based Embedded System with Zigbee wireless communication

module etc. Speed limit of each sign board can be configured by the authority by using keypad. The

system uses wireless methods for the communication using ZIGBEE Trans

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6359(Online), Volume 6, Issue 4, April (2015), pp. 01-10© IAEME

2

is a chance for accident. So there is an utmost need to design a system which

can control the speed of vehicles. Here we are designing a speed control system for vehicles which

can intimate the driver about the zones and limit speed of the vehicle automatically

This paper develops an intelligent speed adaptation, which can monitor the vehicle speed and

implements an action when the vehicle is detected to be exceeding the speed displayed in the speed

[2]. The speed display boards are working as per the highway speed limiting

protocol. The driver should take great attention on the speed of the vehicle especially when driving

through busy junctions, railway crossings, school and college zones etc[3].The citizens are ought to

speed enforcement rules in order to avoid the accidents, any violation in this are considered

Police are authorized to check every vehicle and take actions against the

[4]. But it may not be practically possible always. The proposed system is designed in such

a way that the vehicle speed is automatically controlled through over a wireless communication

The figure 1 shows electrical circuit demonstration for the working of a two wheeler. It has

an excitor coil which is excited by flywheel of two wheeler. It has a magnet which induces ac

voltage to the circuit. It has also a pulse rotor. It has one magnet and induces a dc voltage in the

trigger circuit of SCR. The rotation of which depends on the requirement of speed.

Demonstration circuit of existing system

There is an ignition stop switch when it is closed and charges the capacitor .There is a

d1 through which the capacitor is charged and it is connected to primary of step up transformer.

There will be an SCR, in a solid state device which when triggered discharges the capacitor and

produces ignition .There will be an ignition coil and spark plug which produces spark for ignition of

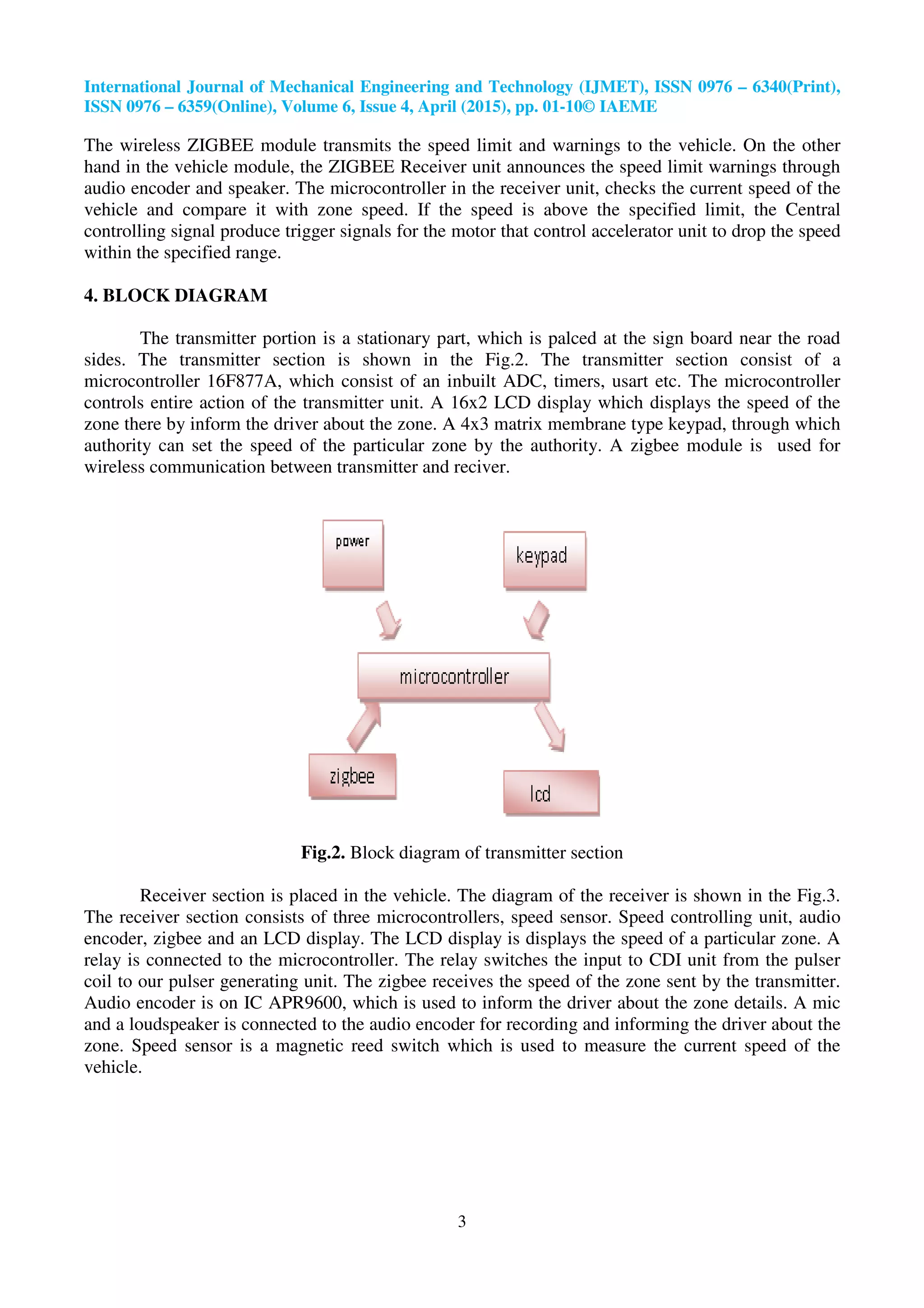

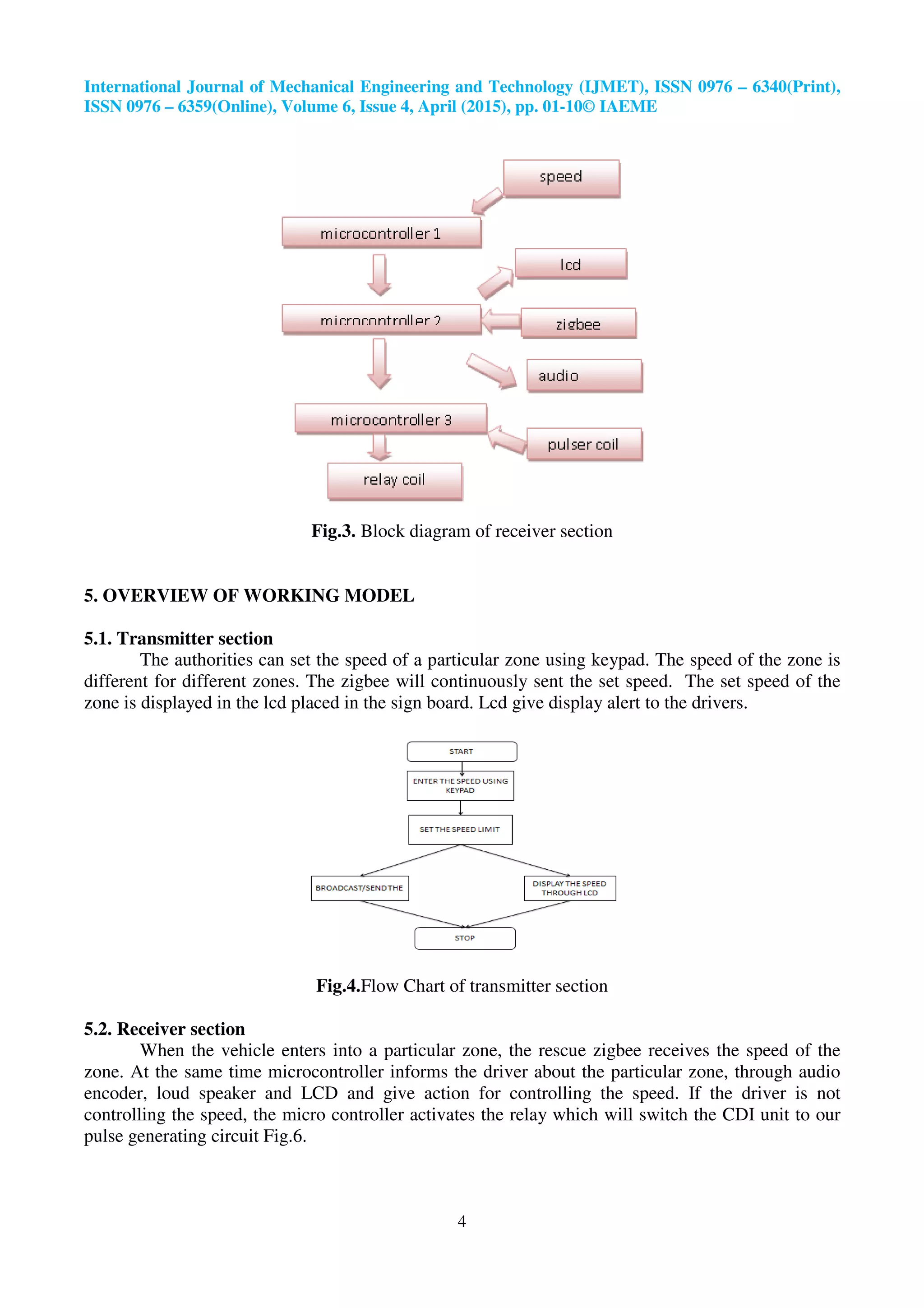

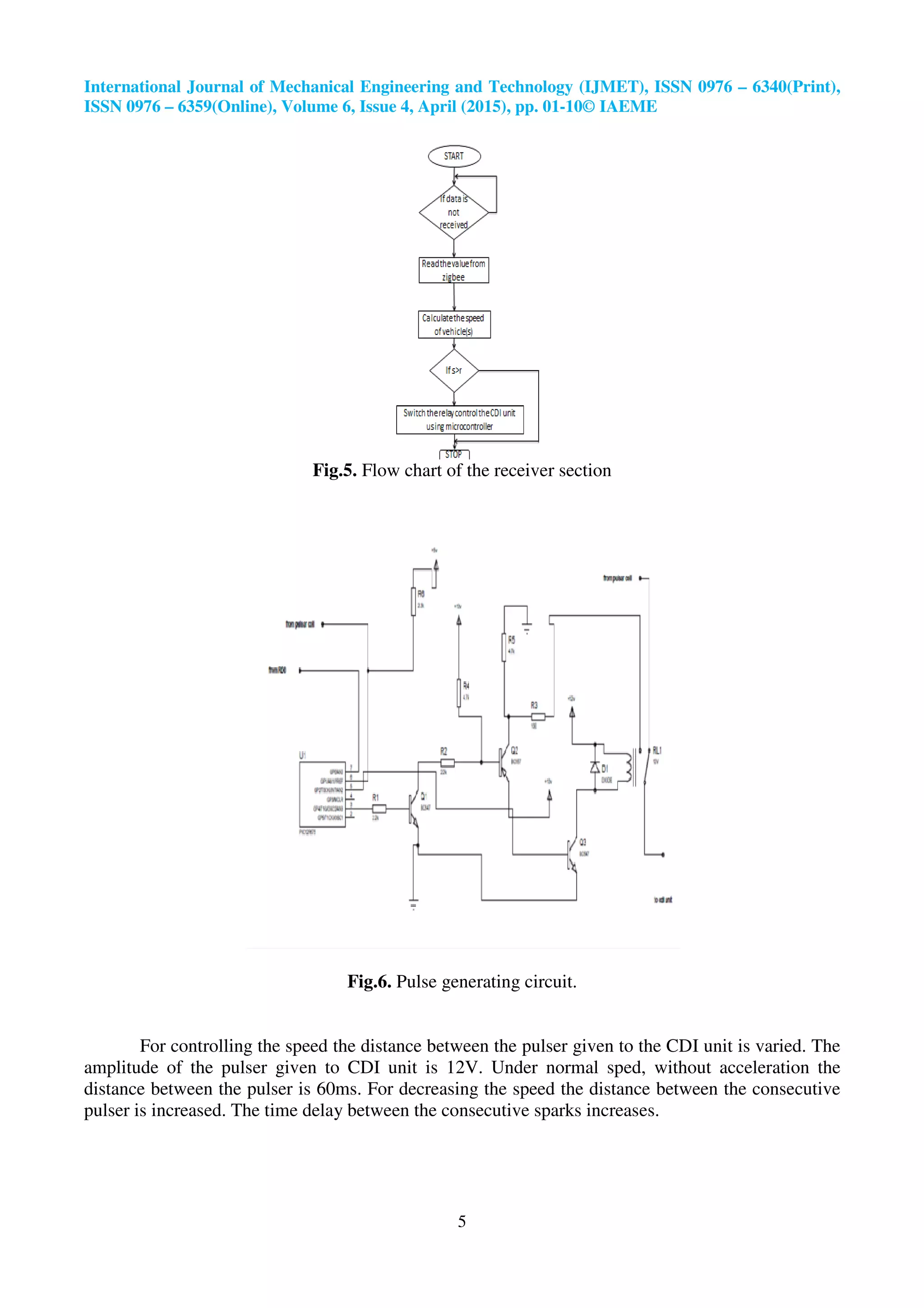

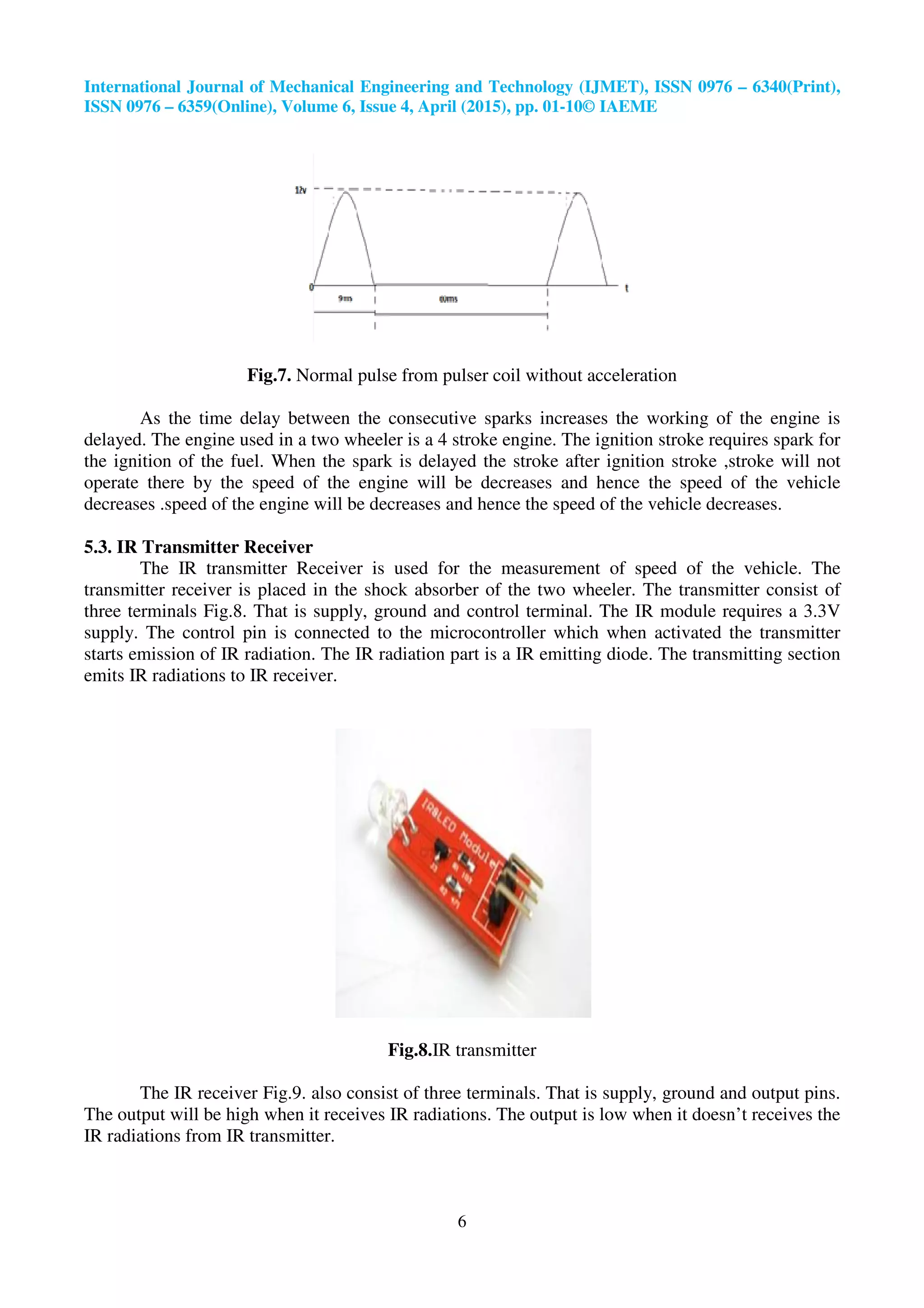

consists of two microcontroller based embedded modules [2]

connected, one in the speed display board and the other inside the vehicle. The module at display

Microcontroller based Embedded System with Zigbee wireless communication

limit of each sign board can be configured by the authority by using keypad. The

system uses wireless methods for the communication using ZIGBEE Trans- Receive module.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

. So there is an utmost need to design a system which

can control the speed of vehicles. Here we are designing a speed control system for vehicles which

tically [1].

This paper develops an intelligent speed adaptation, which can monitor the vehicle speed and

implements an action when the vehicle is detected to be exceeding the speed displayed in the speed

are working as per the highway speed limiting

protocol. The driver should take great attention on the speed of the vehicle especially when driving

through busy junctions, railway crossings, school and college zones etc[3].The citizens are ought to

speed enforcement rules in order to avoid the accidents, any violation in this are considered

Police are authorized to check every vehicle and take actions against the

ys. The proposed system is designed in such

a way that the vehicle speed is automatically controlled through over a wireless communication

The figure 1 shows electrical circuit demonstration for the working of a two wheeler. It has

wheeler. It has a magnet which induces ac

and induces a dc voltage in the

trigger circuit of SCR. The rotation of which depends on the requirement of speed.

There is an ignition stop switch when it is closed and charges the capacitor .There is a diode

d1 through which the capacitor is charged and it is connected to primary of step up transformer.

There will be an SCR, in a solid state device which when triggered discharges the capacitor and

ark plug which produces spark for ignition of

of two microcontroller based embedded modules [2]

connected, one in the speed display board and the other inside the vehicle. The module at display

Microcontroller based Embedded System with Zigbee wireless communication

limit of each sign board can be configured by the authority by using keypad. The

Receive module.](https://image.slidesharecdn.com/smart-vehicle-and-smart-signboard-system-with-zonal-speed-regulation-160216130536/75/Smart-vehicle-and-smart-signboard-system-with-zonal-speed-regulation-2-2048.jpg)