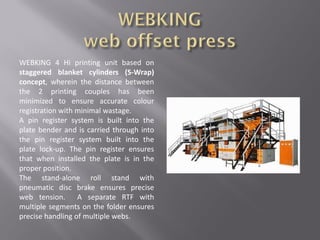

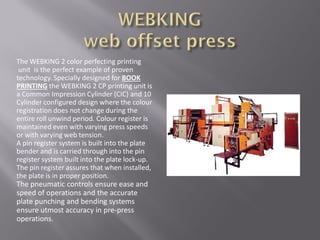

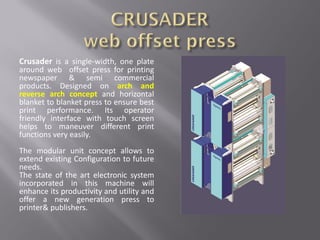

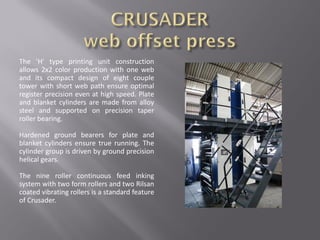

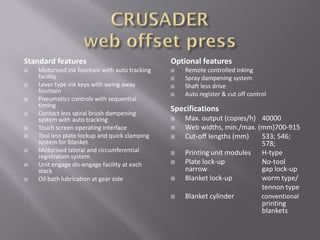

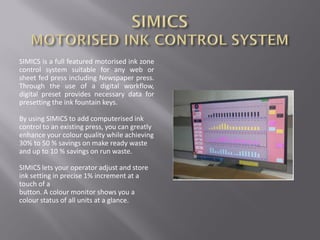

The document describes various models of printing machines, specifically the Orion Webking and Crusader, emphasizing their budget-friendly design, standard and optional features, and user-friendly interfaces. These machines are tailored for different printing needs such as books and newspapers, with advanced color registration systems and robust construction. Additionally, the document highlights SIMICS, a motorized ink zone control system aimed at enhancing color quality and reducing waste during printing.