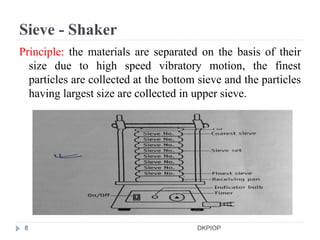

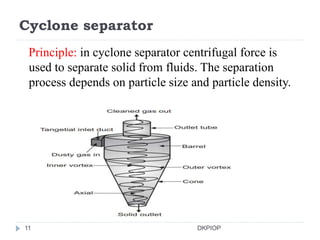

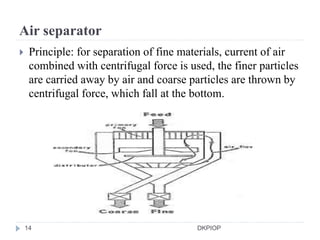

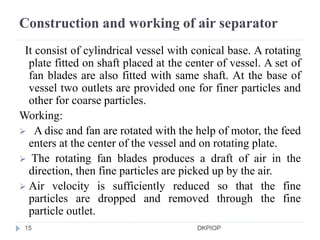

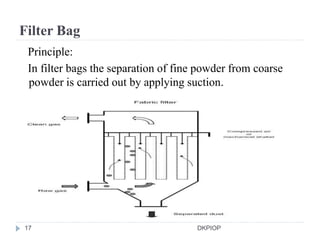

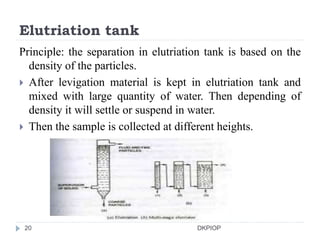

The document discusses various techniques used for size separation of particles in pharmaceutical processes. It defines different powder sizes according to mesh aperture sizes. Some common size separation methods described are sieving, sieve shaker, cyclone separator, air separator, filter bags, and elutriation tank. Sieving involves agitation of powders on mesh screens to separate particles by size. A sieve shaker uses vibration to quickly separate particles. A cyclone separator and air separator use centrifugal forces and air currents respectively to separate particles. Filter bags apply suction to separate fine powders, while an elutriation tank separates particles based on density differences in water.