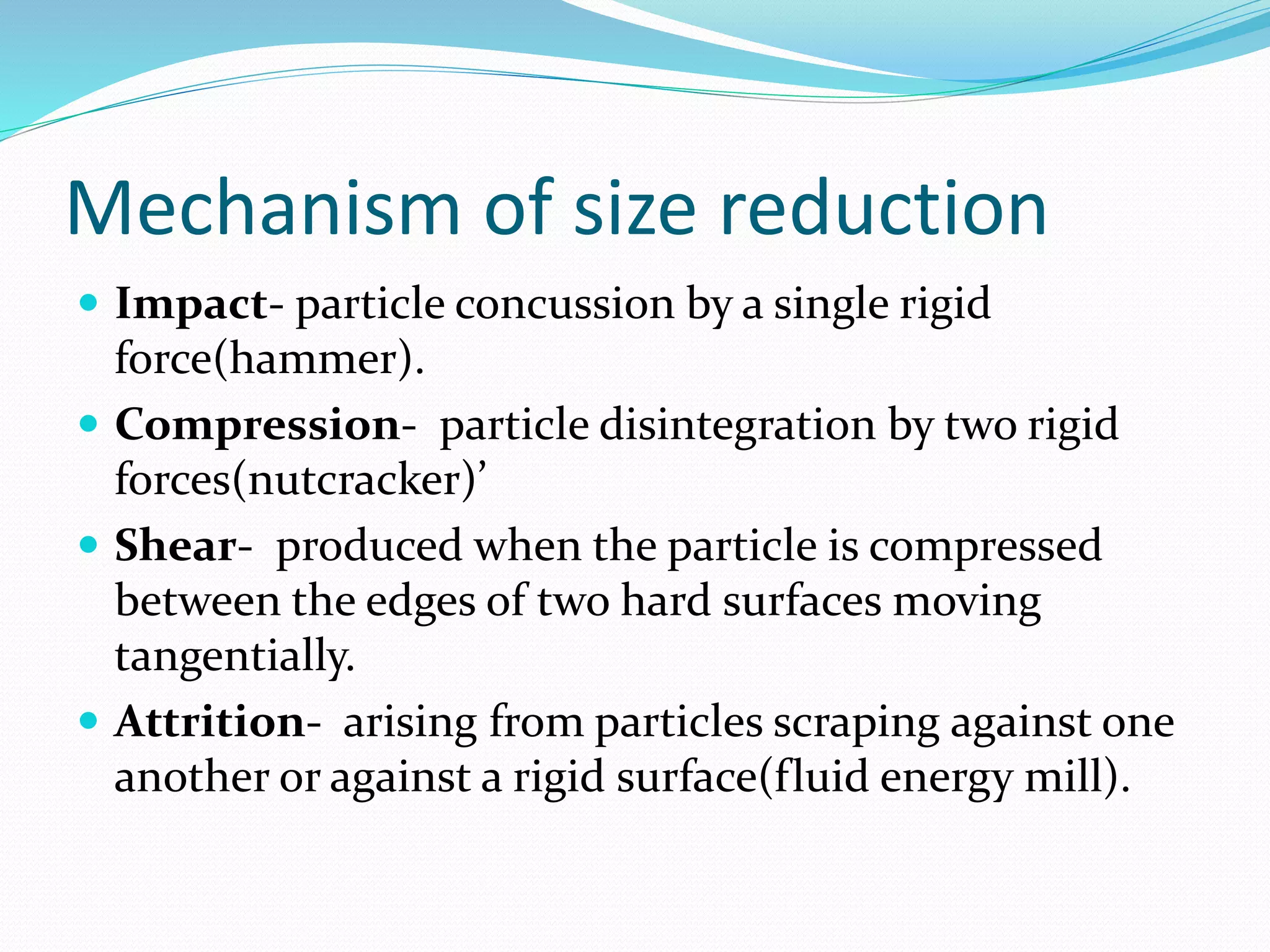

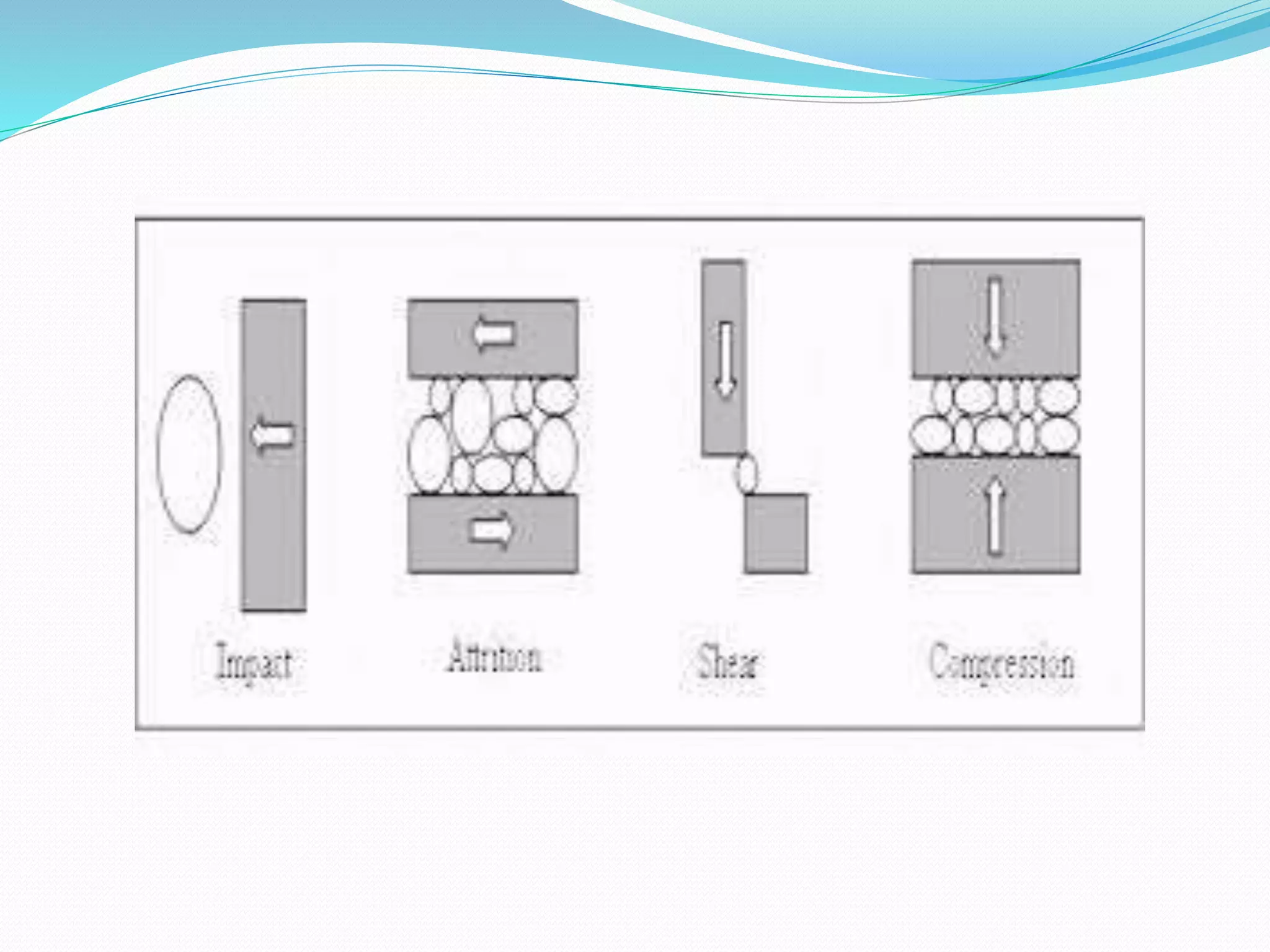

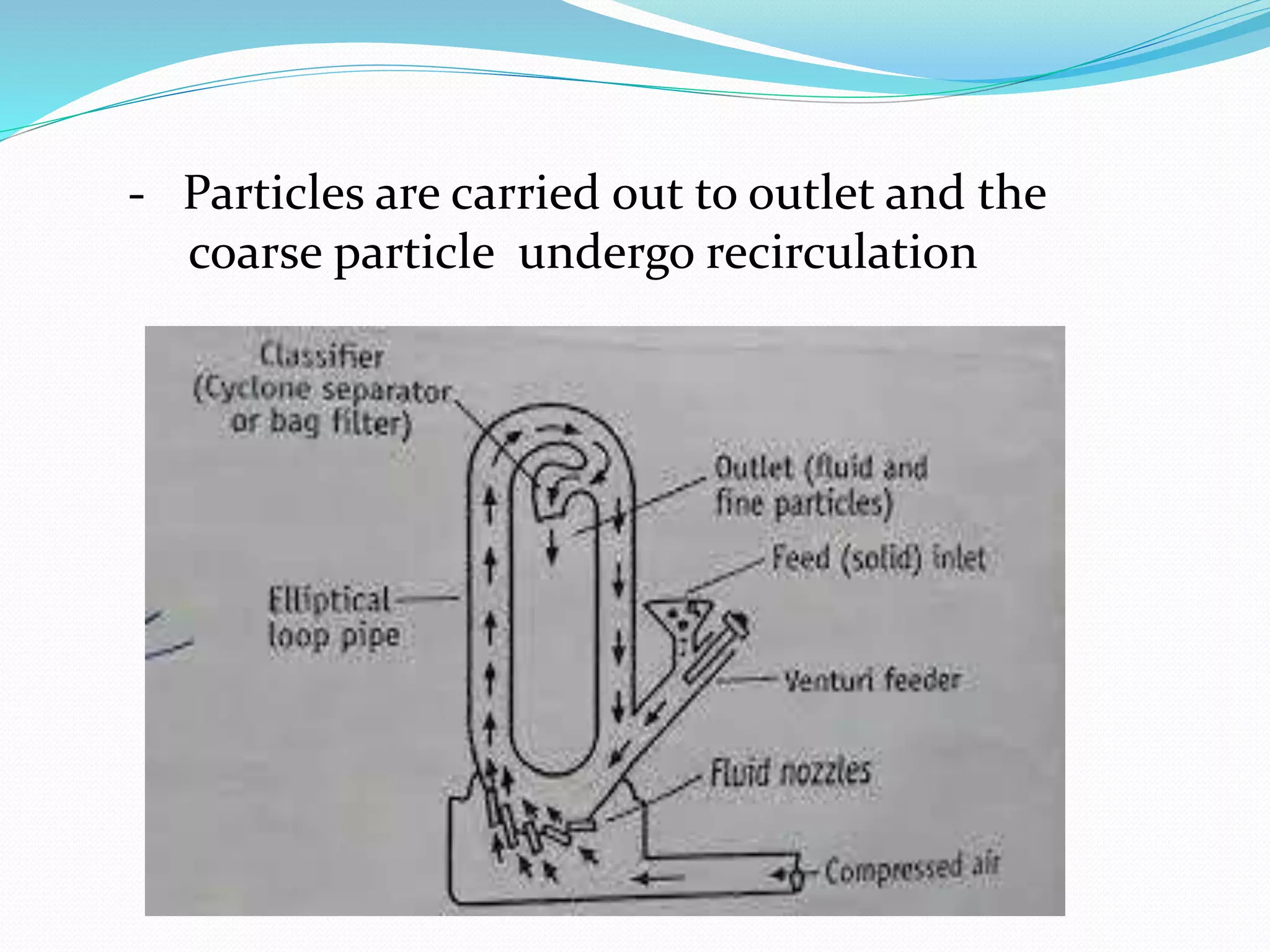

The document discusses various methods of size reduction used in pharmaceutical processing. It describes common size reduction equipment like ball mills, fluid energy mills, colloidal mills, and hammer mills. For each method and equipment, it provides details on working principles, advantages, disadvantages, and applications. It also discusses theories of size reduction proposed by Rittinger, Bond, and Kick which relate energy requirements to changes in particle size and surface area.