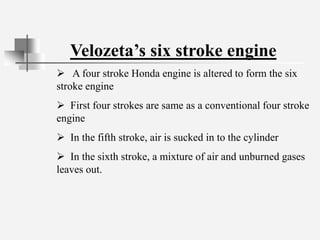

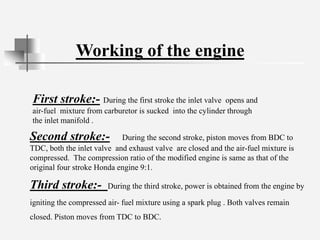

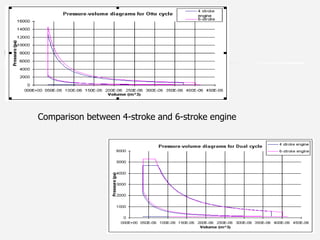

The document describes Velozeta's six-stroke engine, which modifies a four-stroke Honda engine by adding two additional strokes. In the fifth stroke, air is inducted into the cylinder through a reed valve. In the sixth stroke, the exhaust valve remains open and a mixture of air and unburned gases is removed. This design promises reductions in fuel consumption and pollution of up to 65% while maintaining the production methods of a conventional four-stroke engine. The six-stroke engine could find applications in racing cars, heavy vehicles, and earth moving equipment.