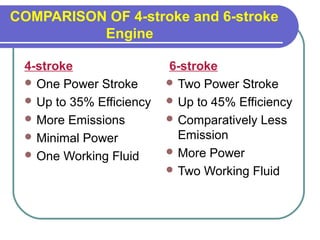

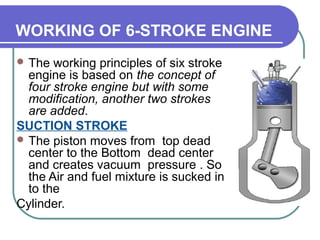

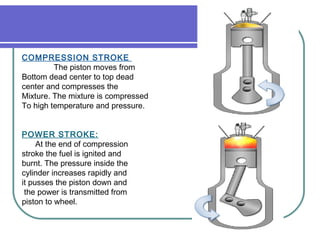

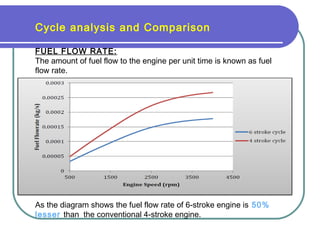

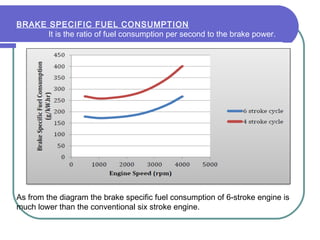

The document describes a 6-stroke engine that aims to increase efficiency and reduce emissions compared to a conventional 4-stroke engine. The 6-stroke engine adds two additional strokes: a secondary power stroke using steam generated from injected water, and a secondary exhaust stroke. This leads to improvements such as up to 45% efficiency, lower fuel consumption and emissions compared to 35% efficiency for a 4-stroke engine. However, challenges include preventing damage from thermal stresses during water injection and addressing weight and space needs of a separate water tank.