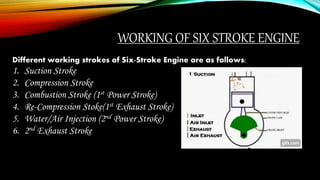

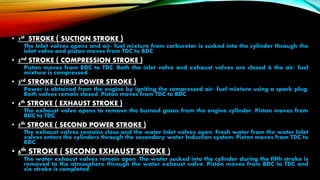

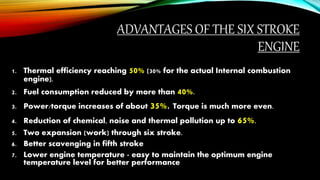

The document discusses the six stroke engine, which differs from a four stroke engine by having two power strokes - one from fuel and one from steam or air. It provides examples of six stroke engine designs and discusses the working strokes. The six stroke engine has higher efficiency than a four stroke engine but also has higher costs due to its more complex design with additional components. While promising for reducing fuel consumption and emissions, commercializing the six stroke engine faces challenges of high initial costs.