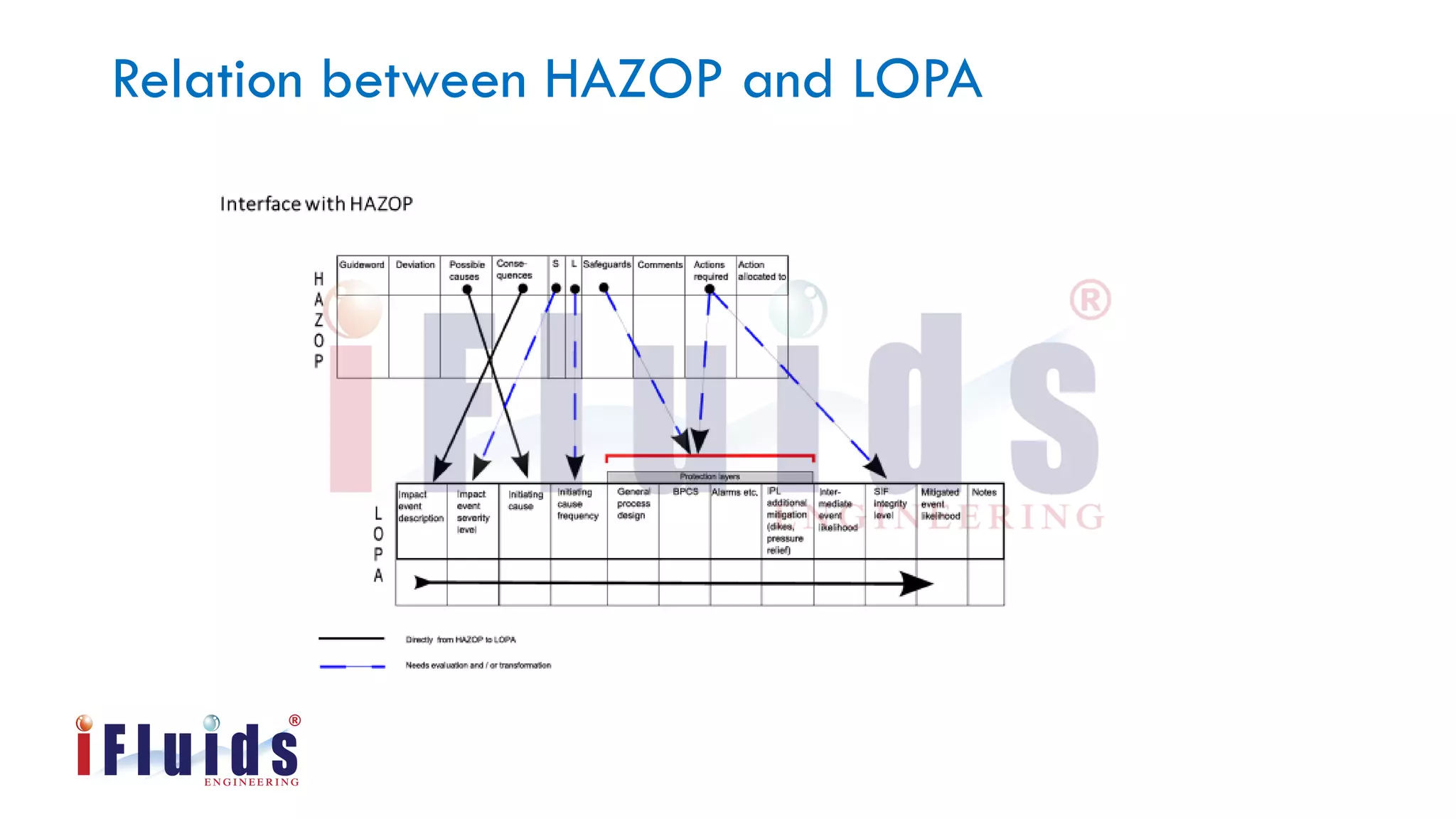

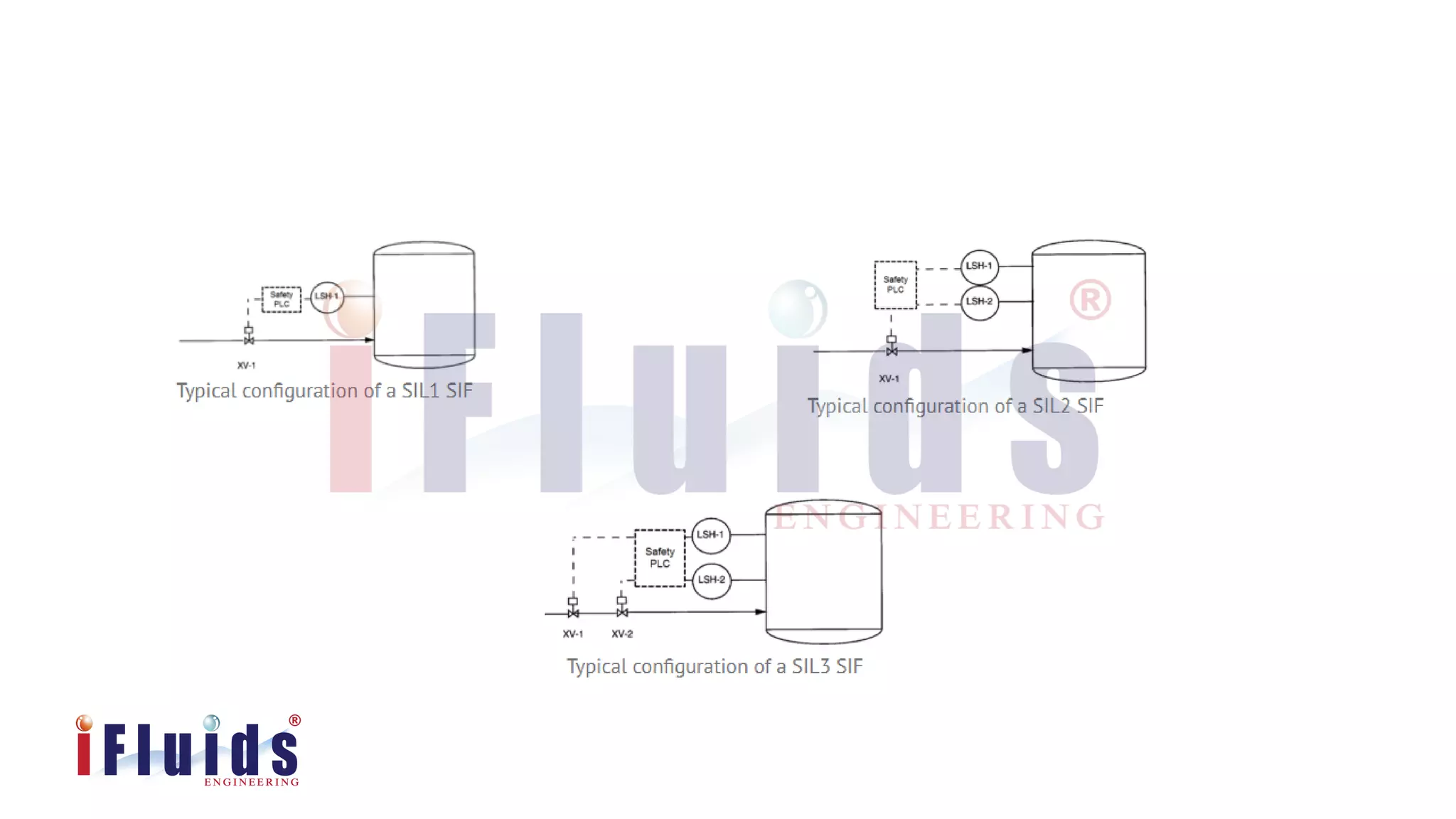

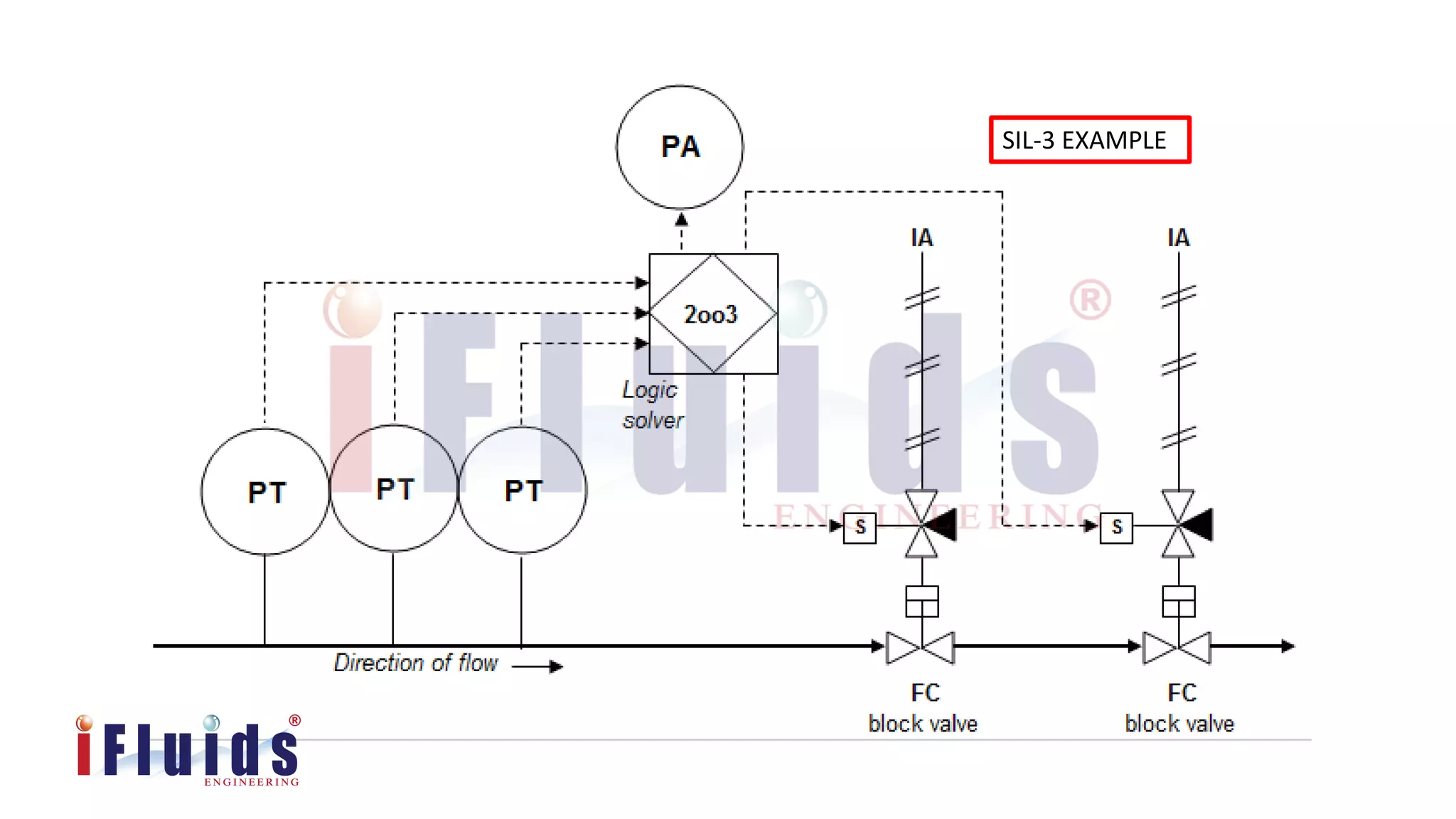

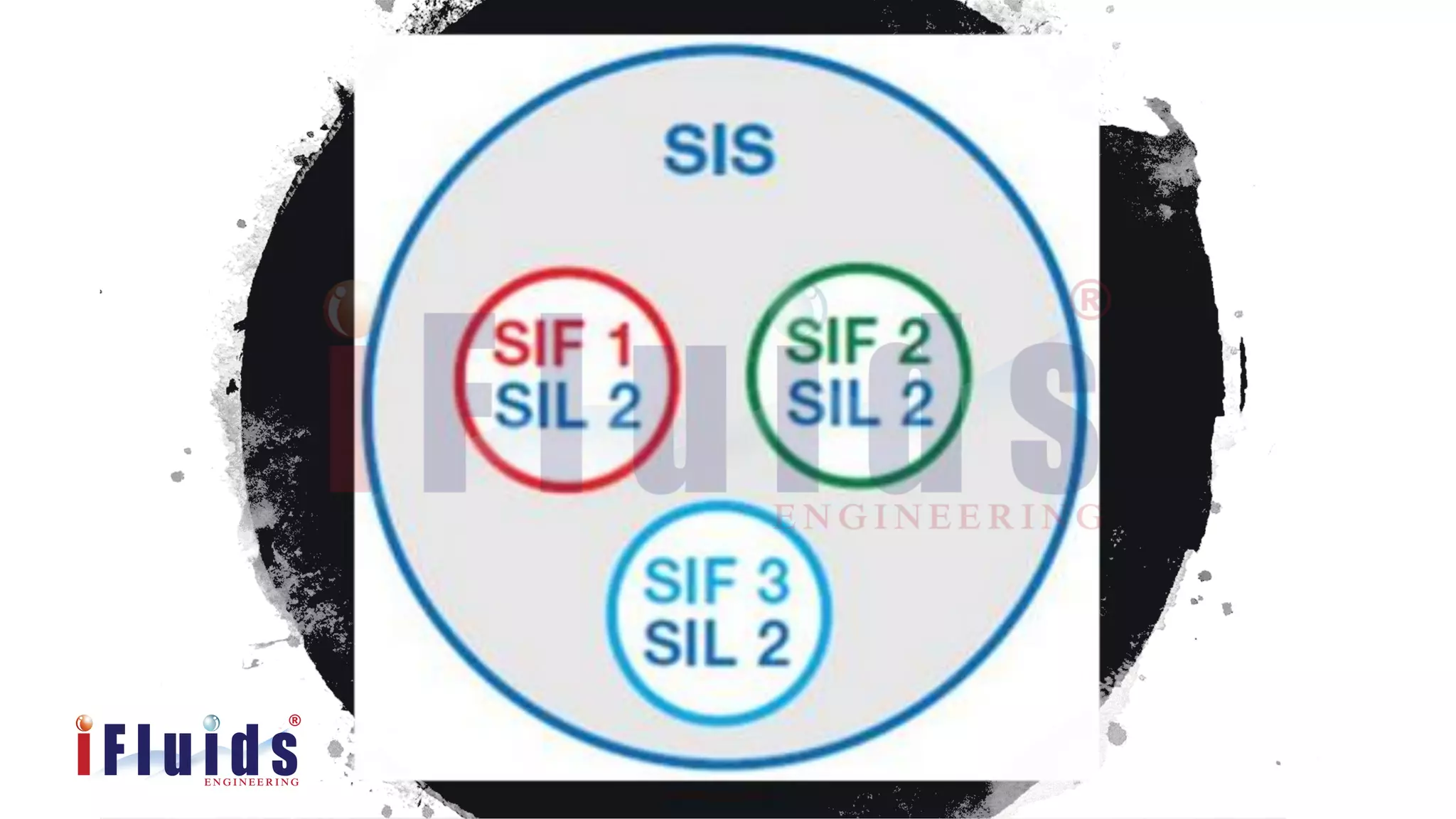

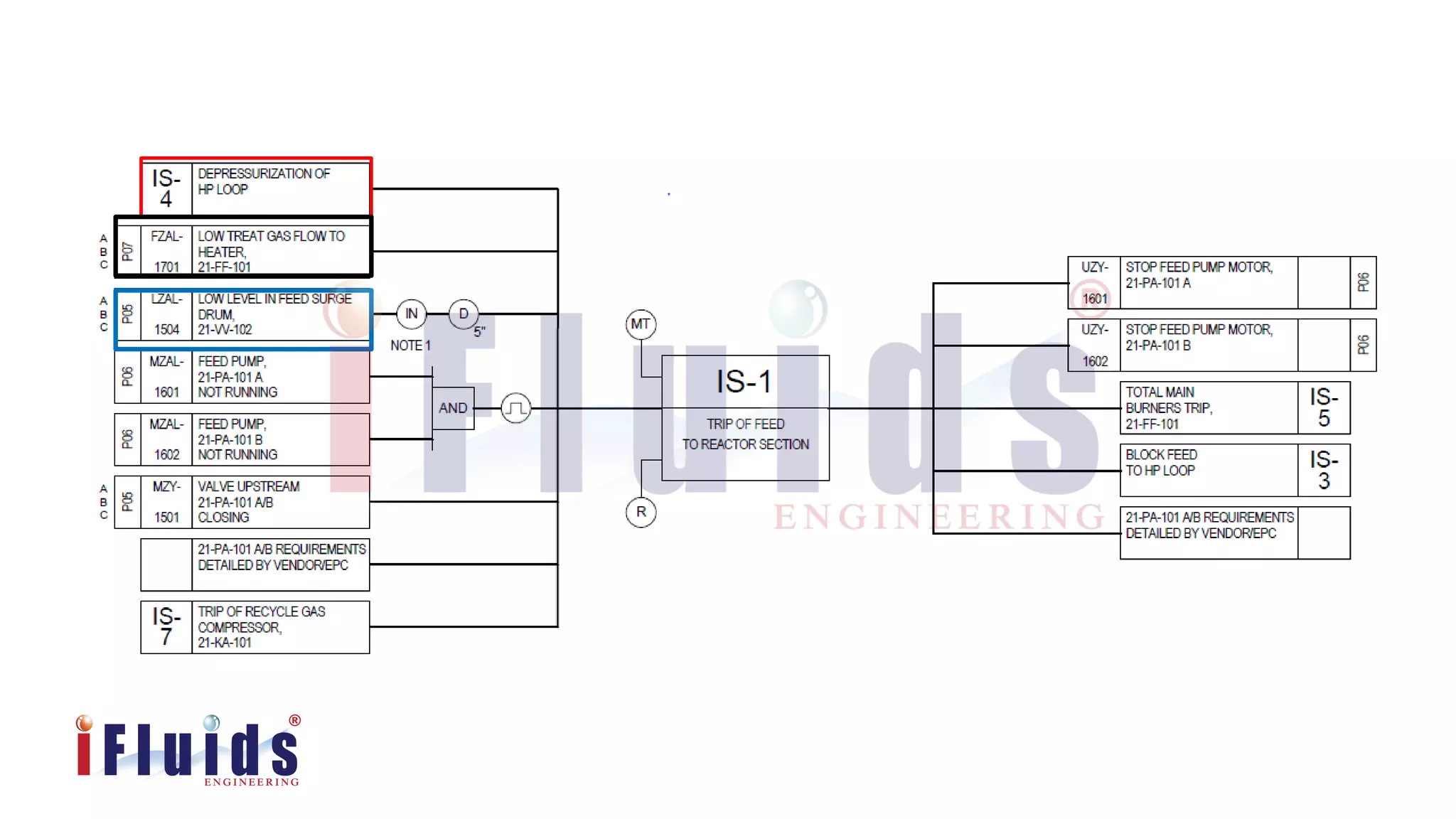

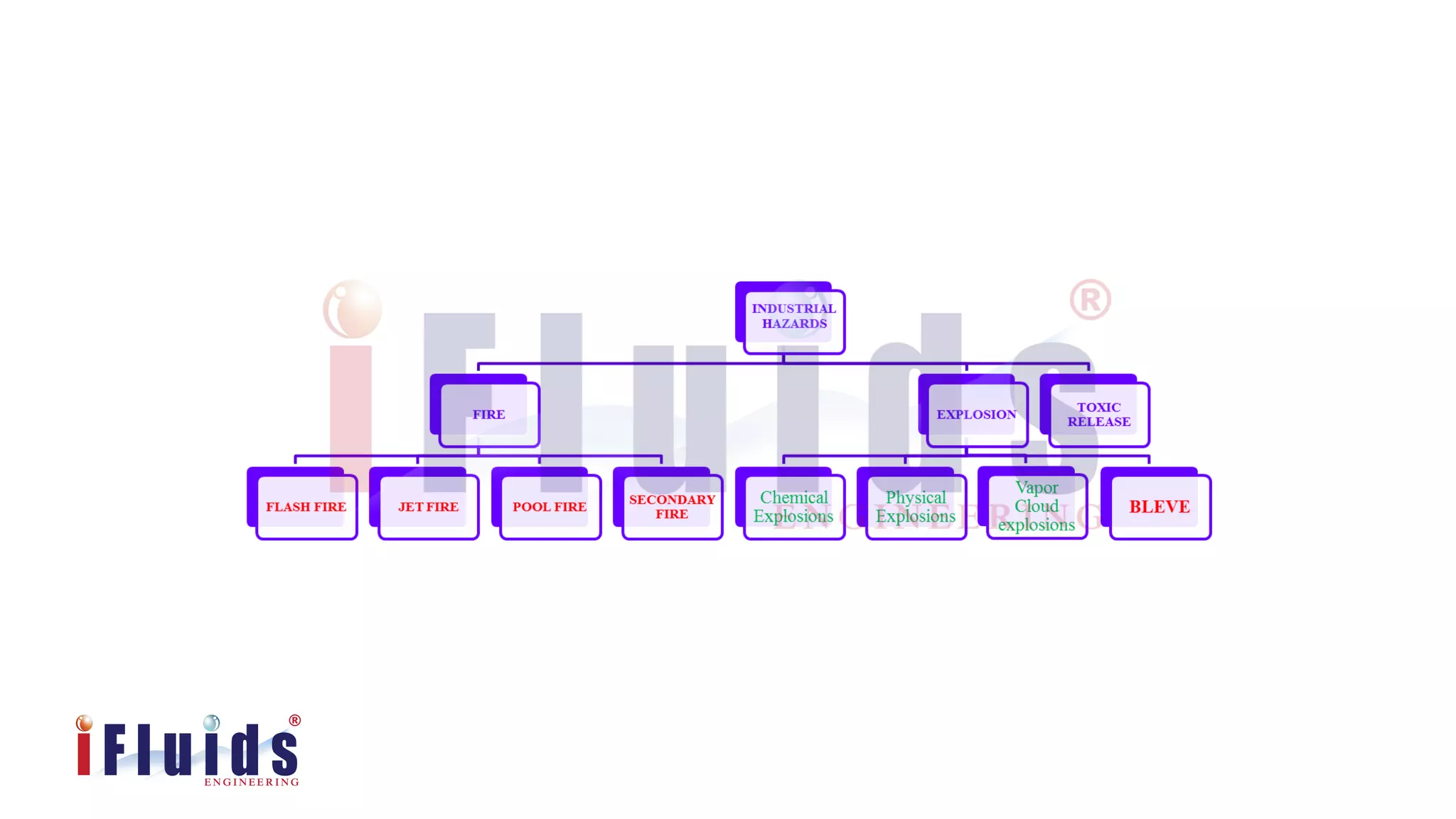

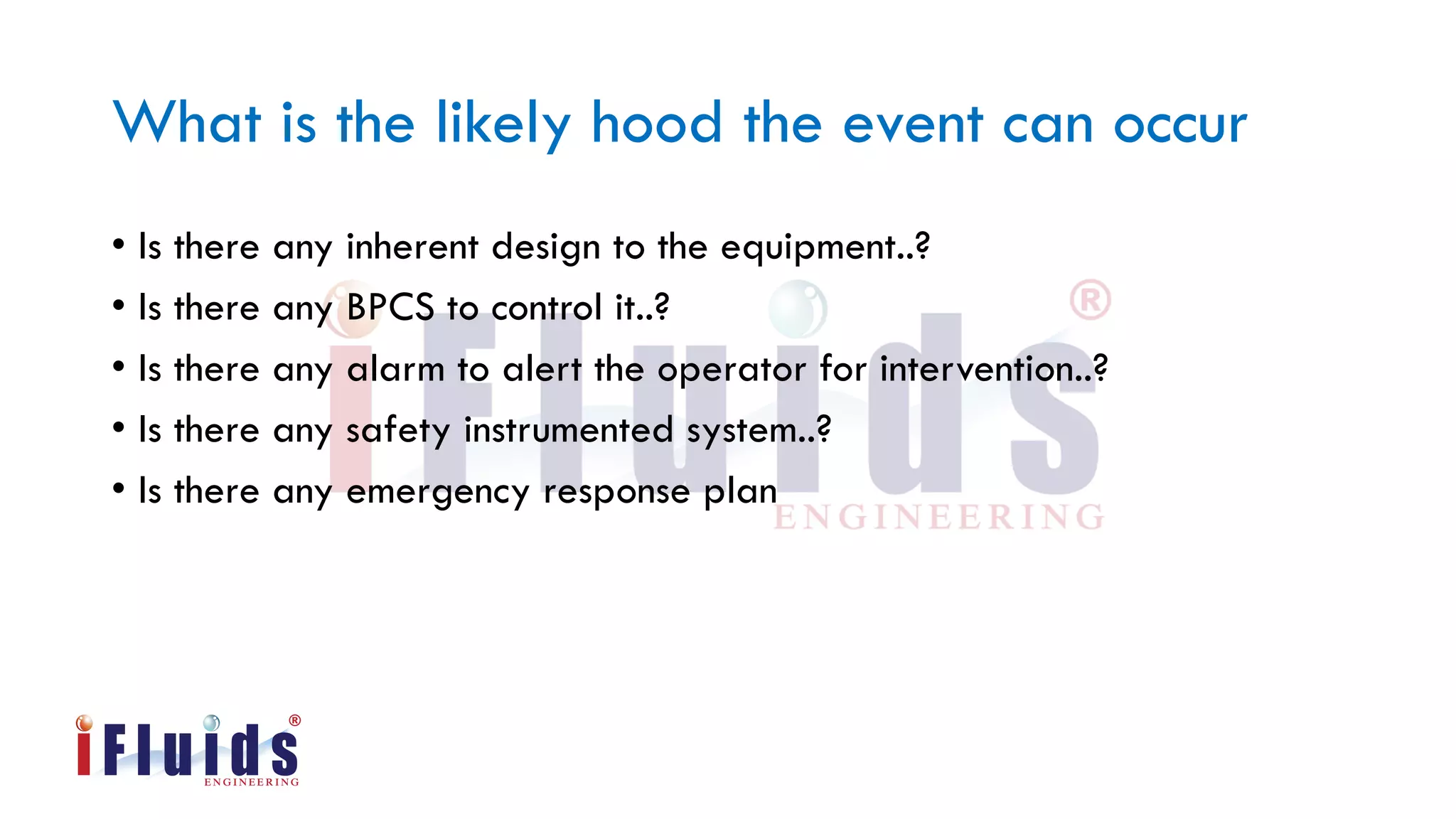

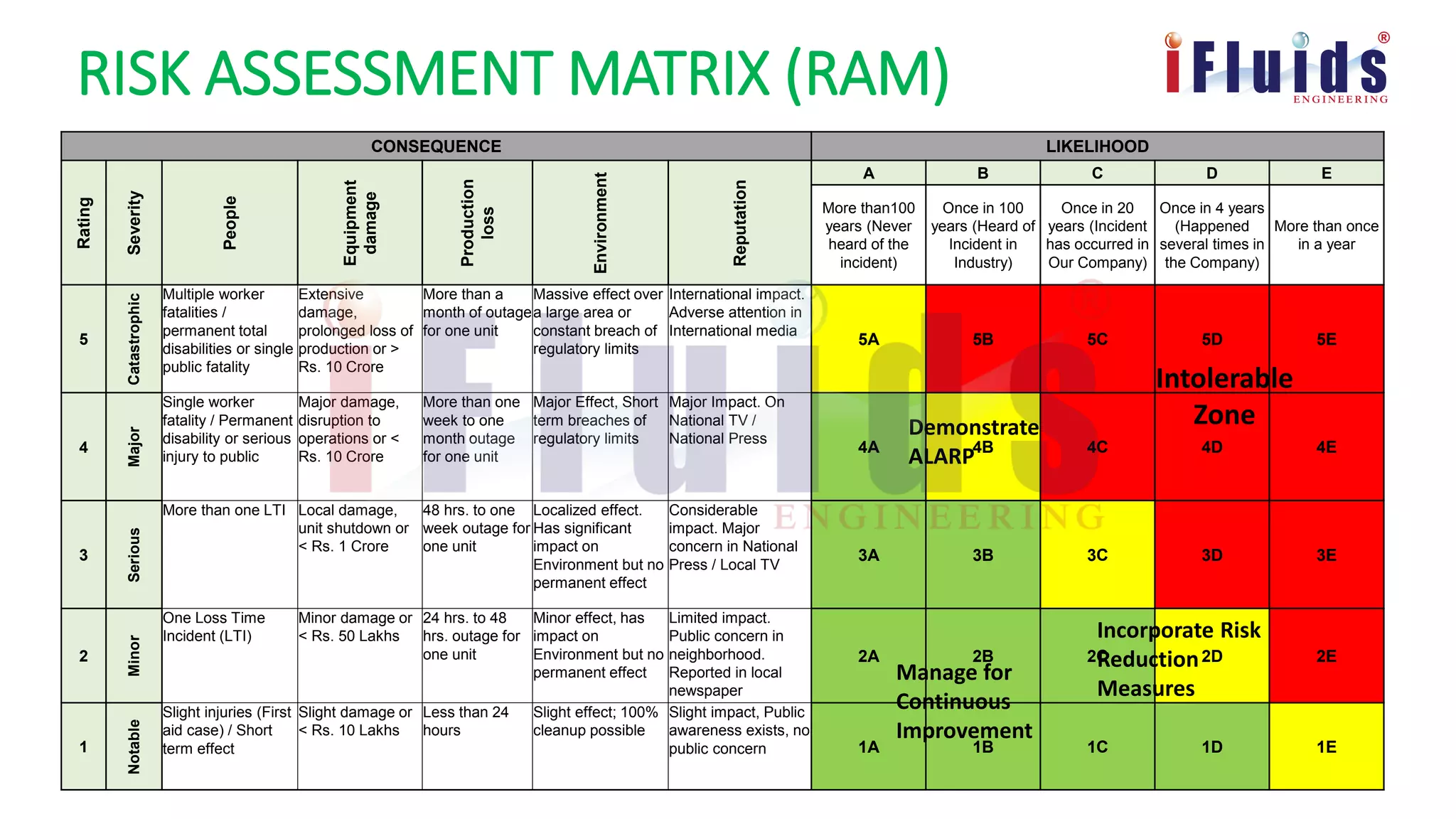

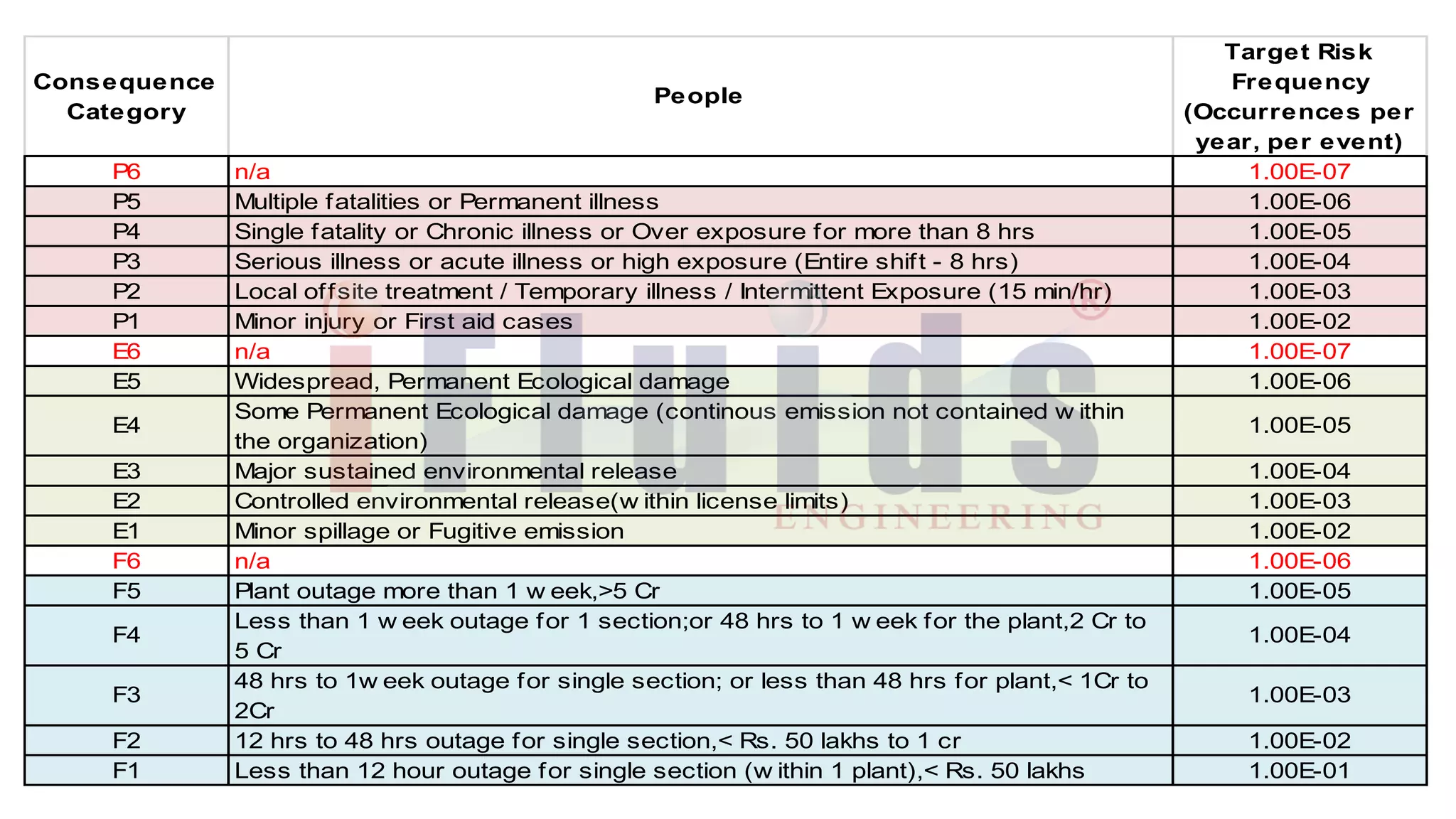

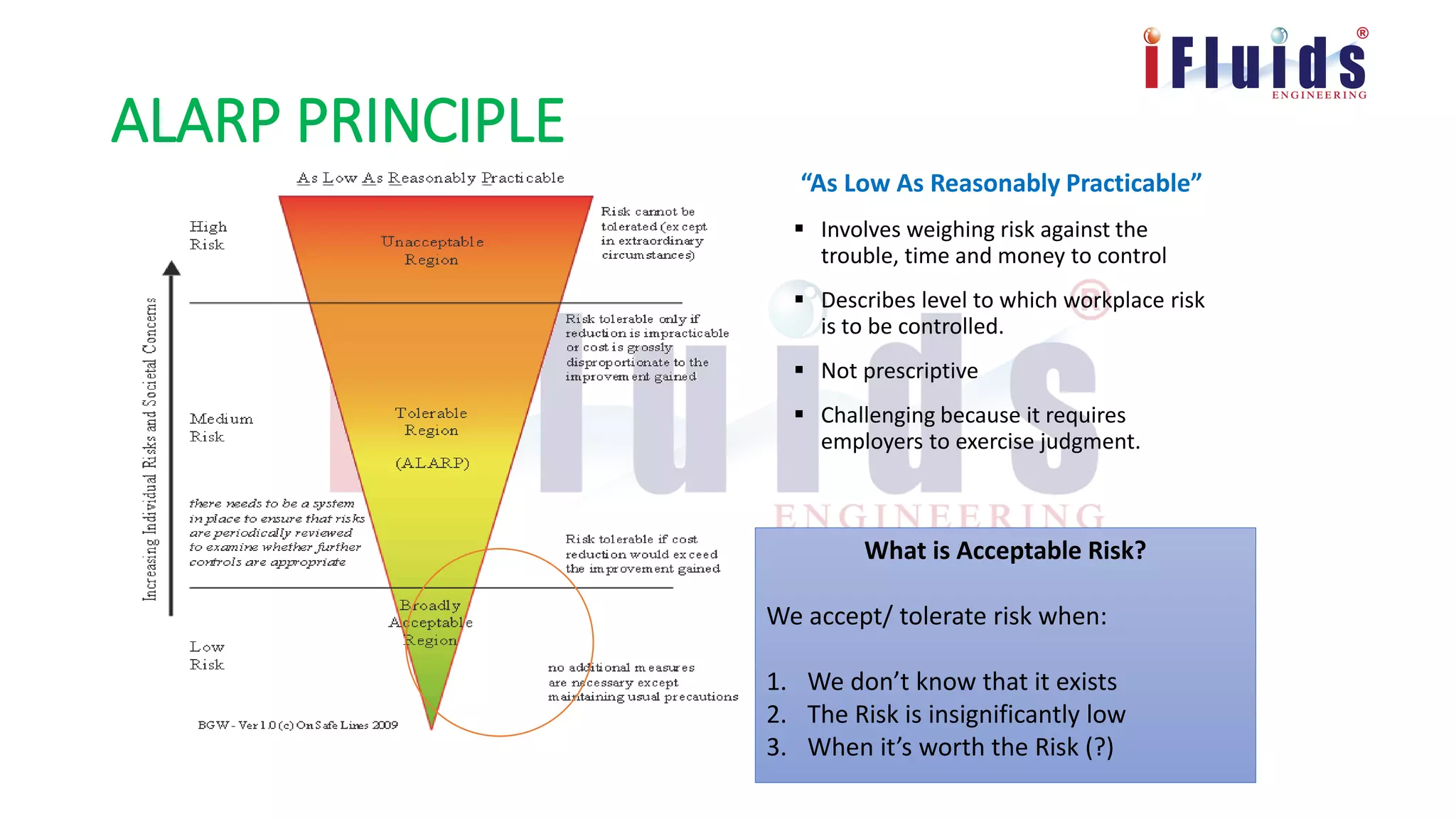

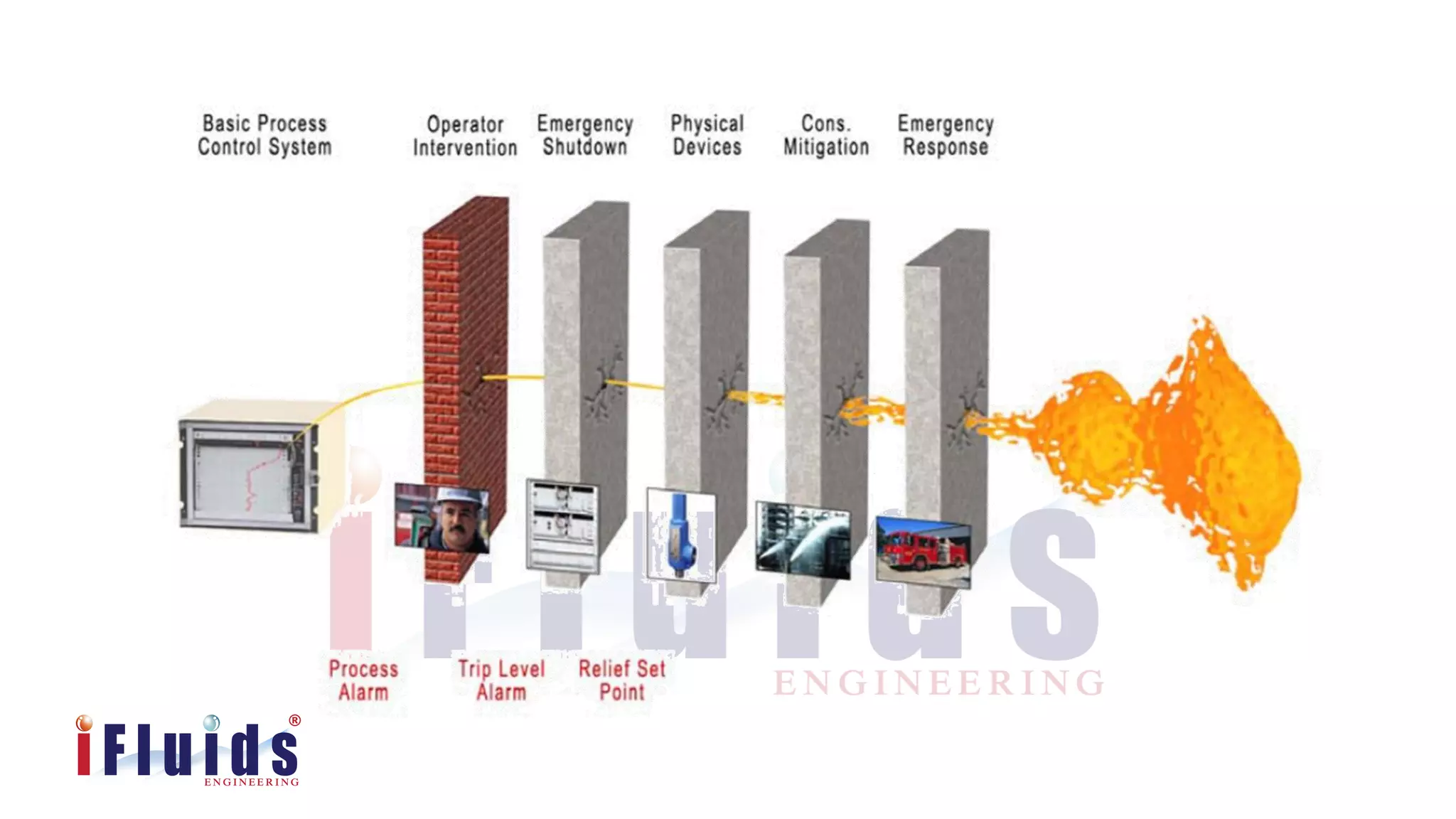

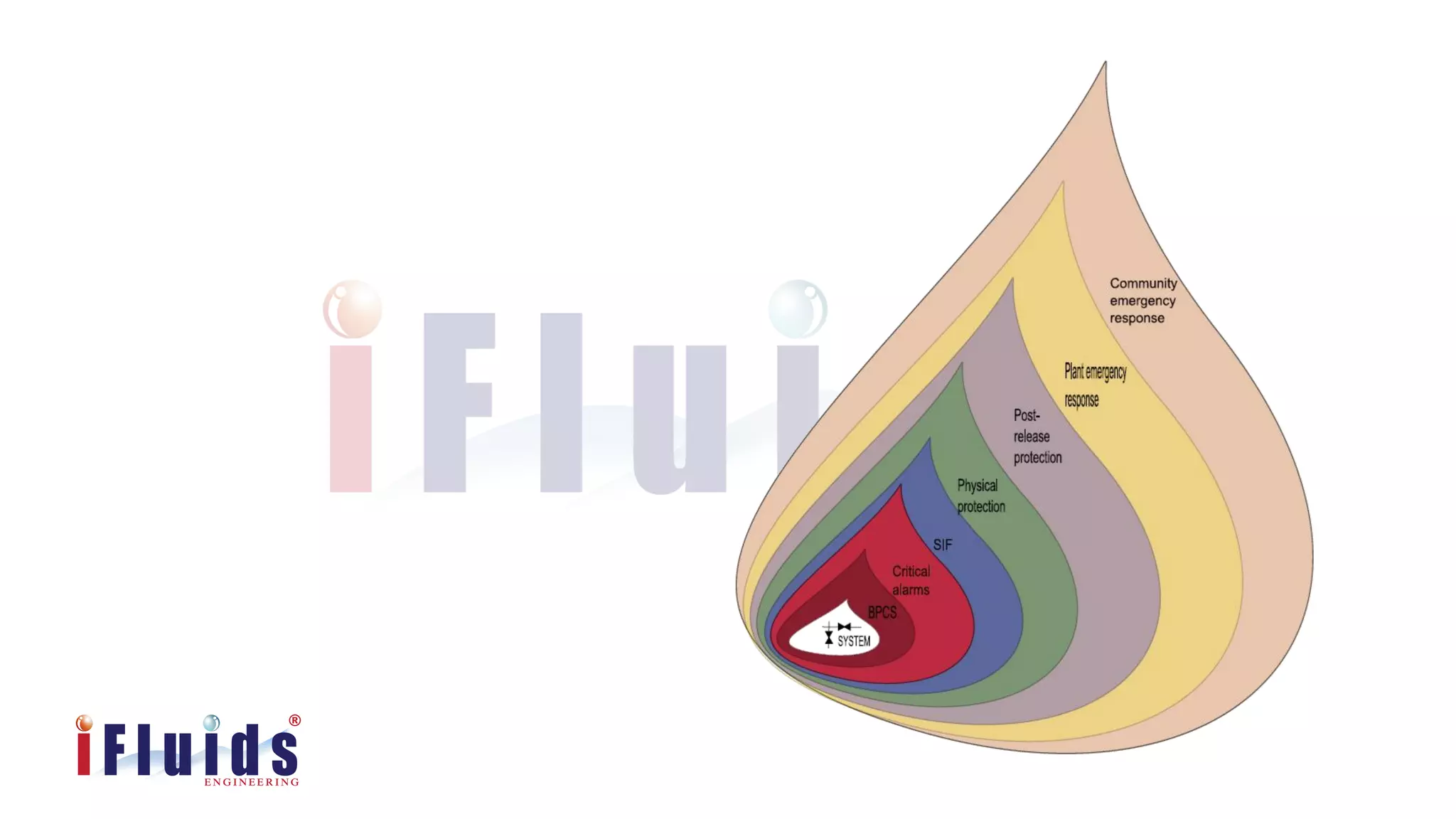

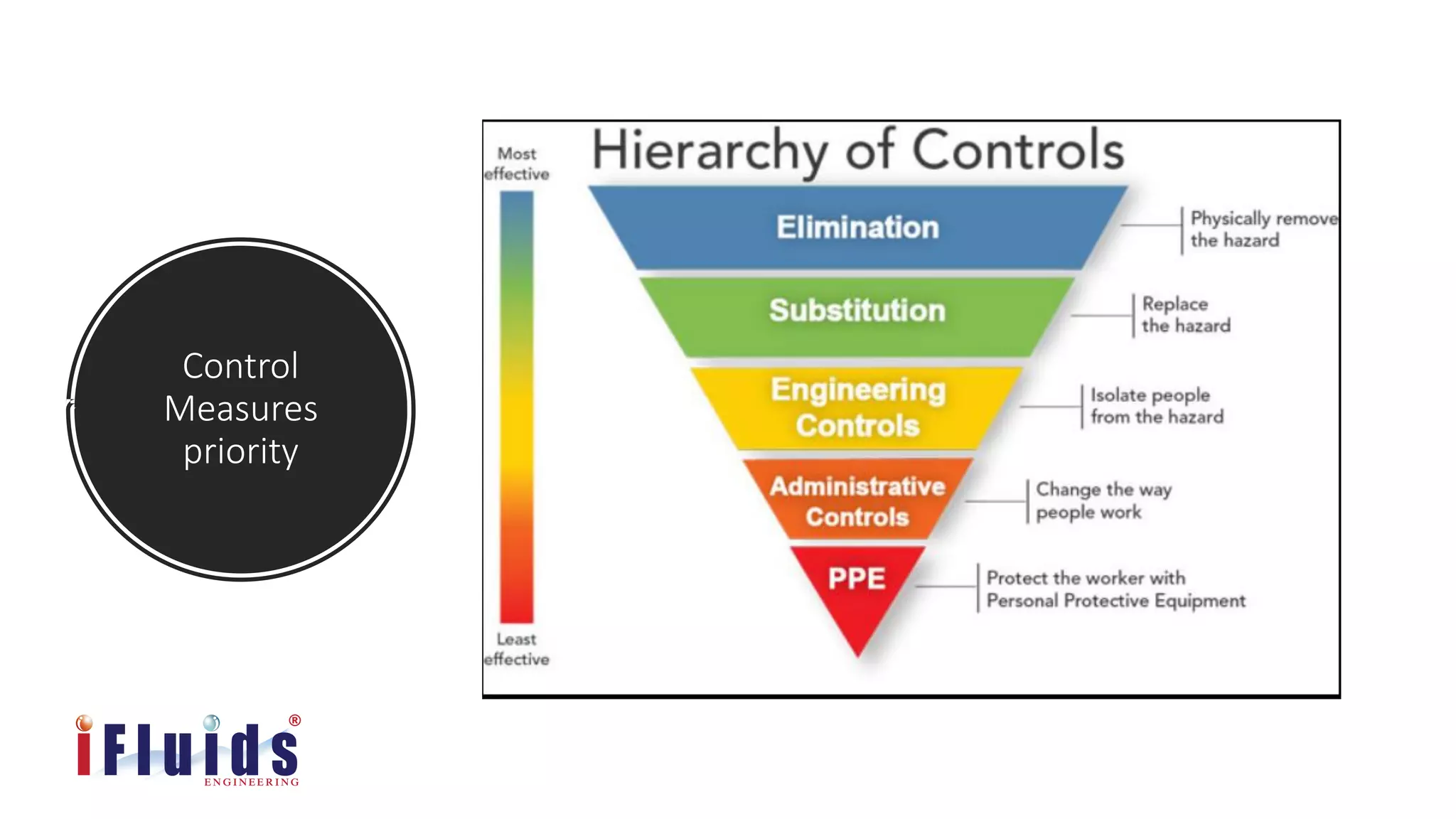

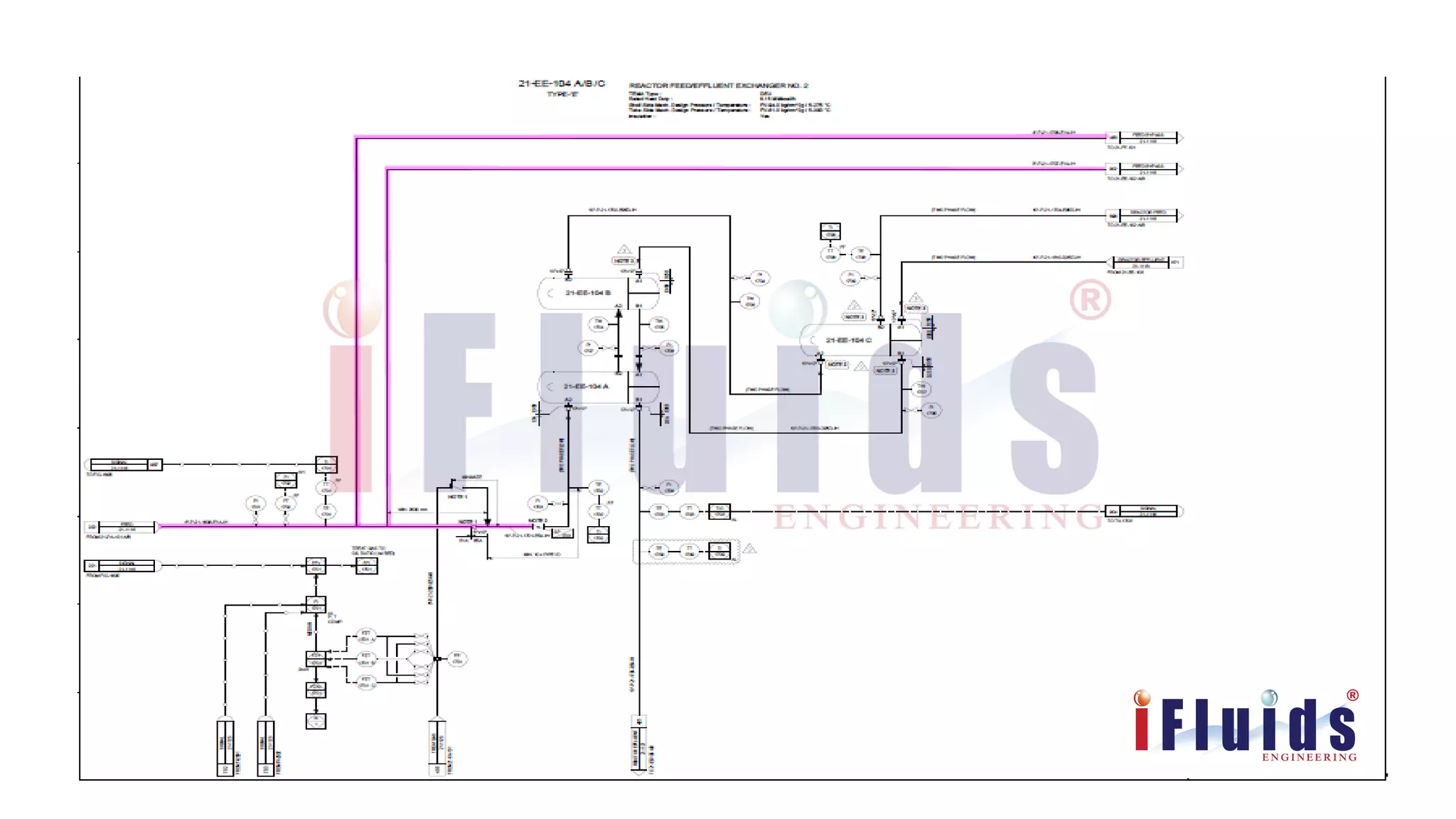

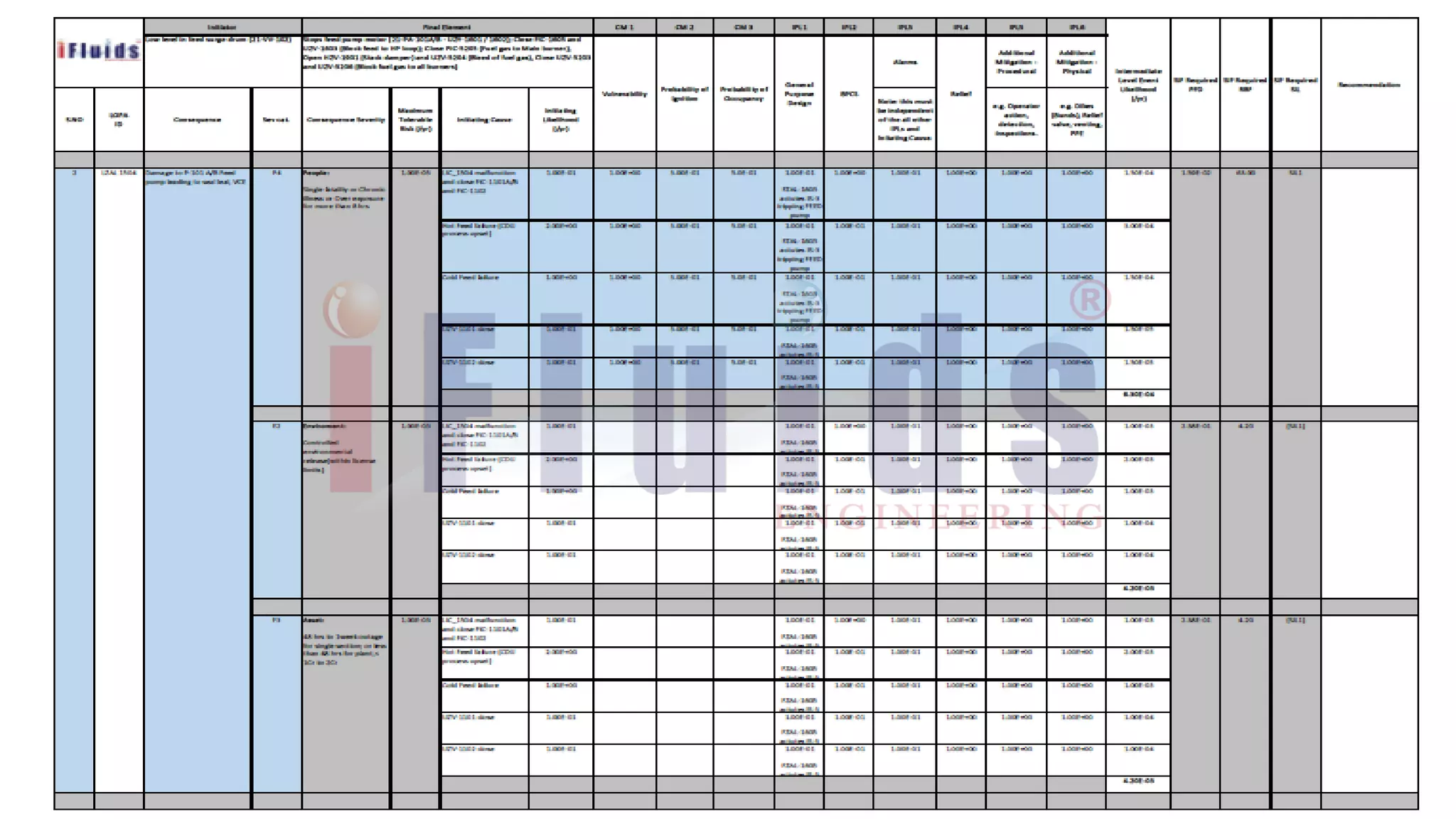

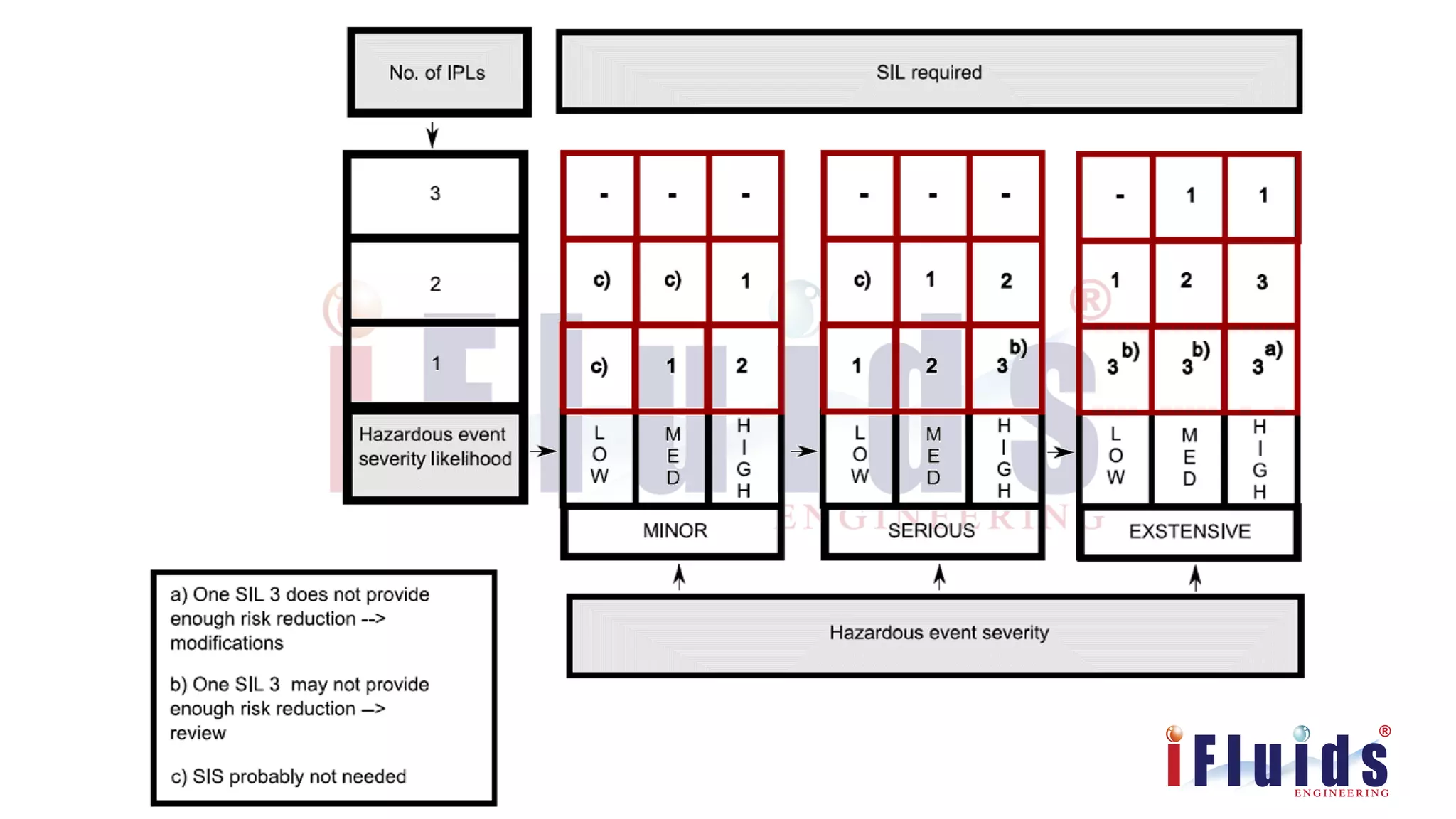

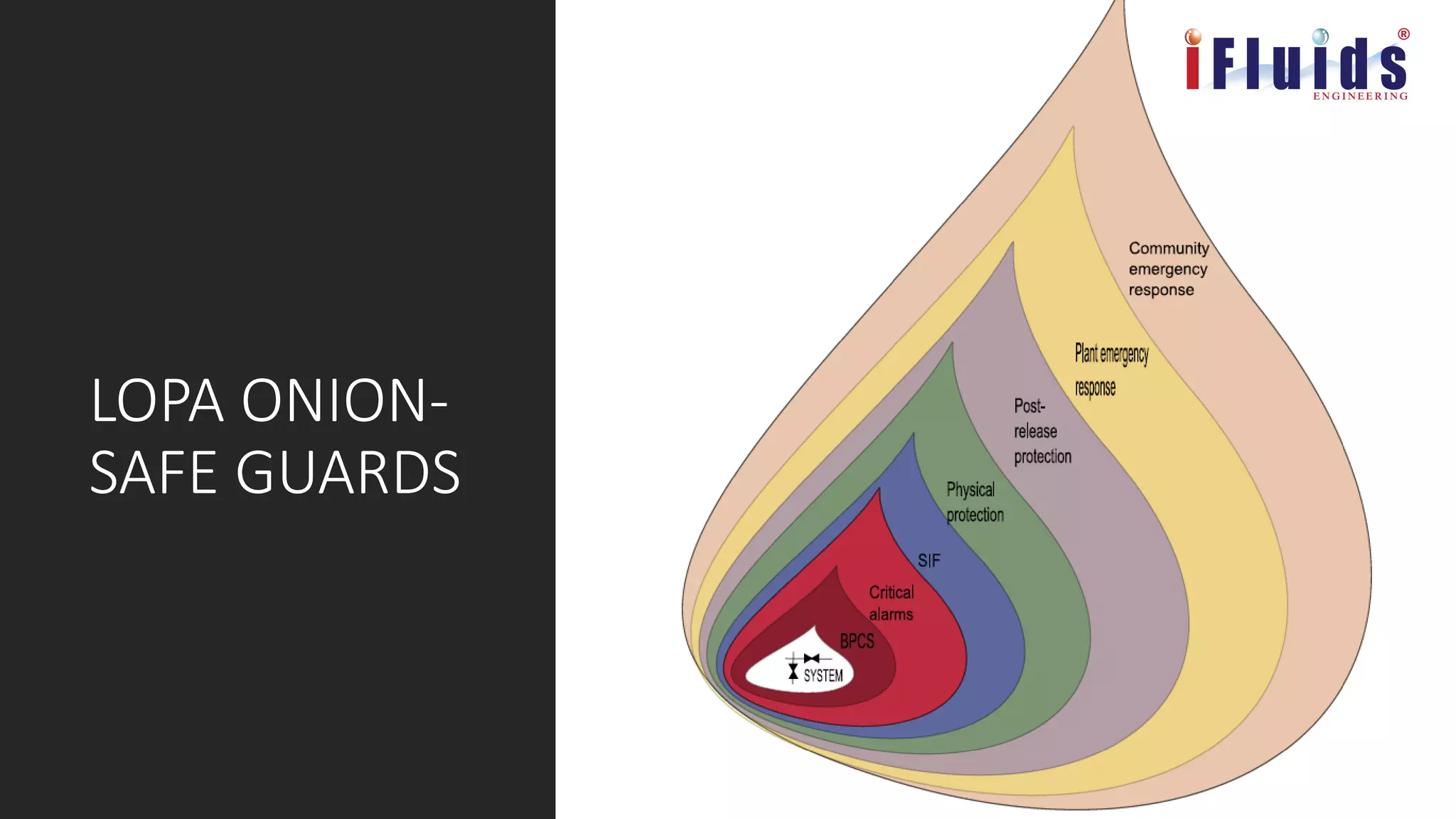

This document provides an overview of SIL assessment and LOPA (layer of protection analysis) techniques. It discusses the differences between HAZOP and SIL studies, and the relationship between HAZOP and LOPA. Key aspects covered include safety integrity levels (SIL), risk matrices, consequence analysis, likelihood analysis, establishing tolerable risk levels using the ALARP principle, and control measure prioritization. Examples are provided of a SIL-3 assessment and applying the risk graph method.