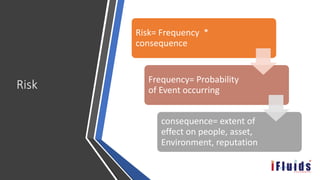

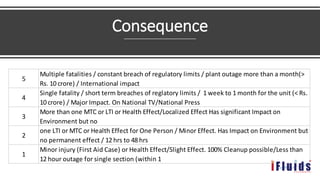

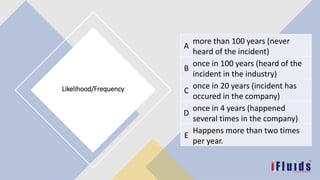

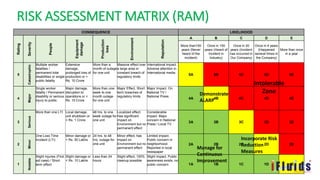

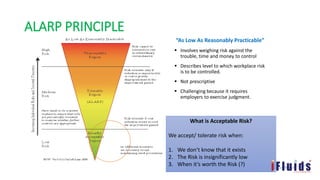

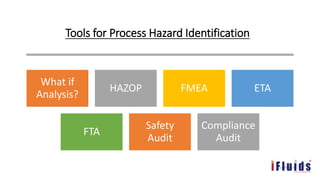

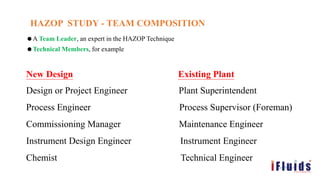

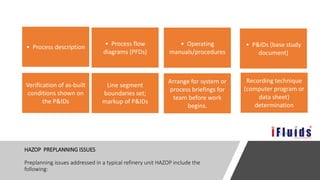

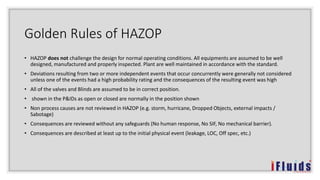

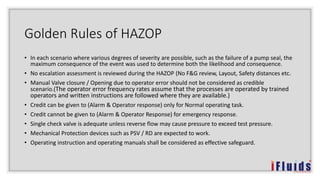

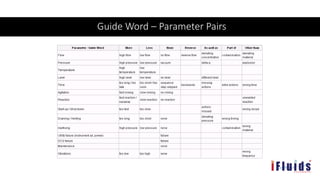

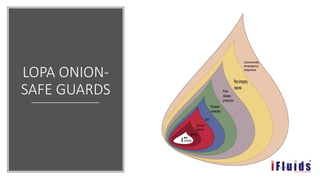

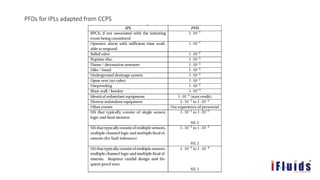

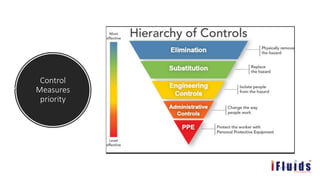

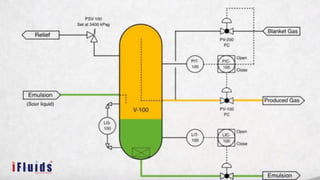

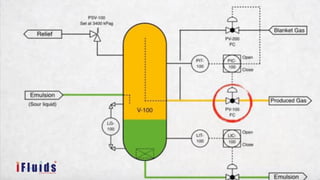

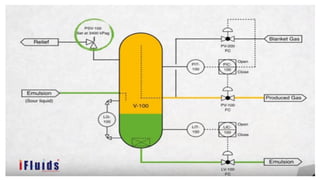

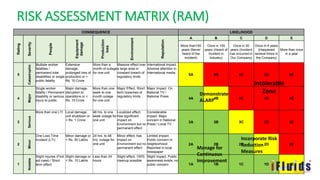

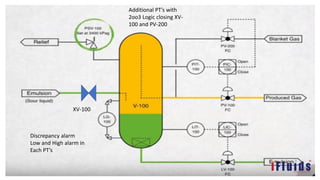

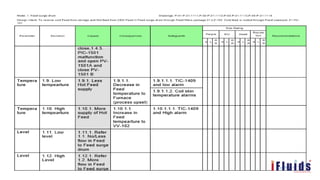

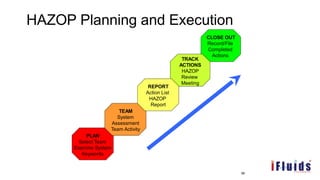

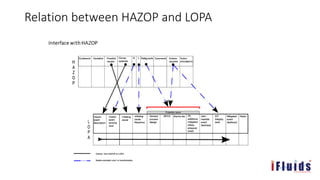

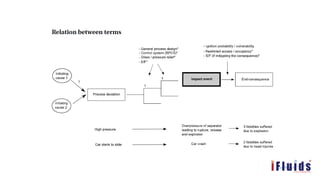

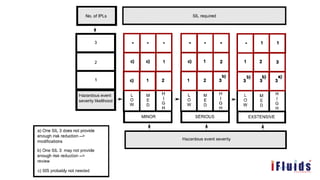

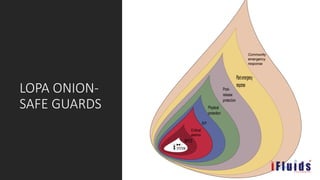

The document outlines the curriculum for an intermediate HAZOP (Hazard and Operability Study) training course, covering key concepts like risk assessment, team composition, and methodology. It details the definitions of hazards and risks, the importance of various terms, and the application of the ALARP (As Low As Reasonably Practicable) principle in managing risks. Additionally, it highlights the structured approach to HAZOP studies, including the identification of hazards and the evaluation of their consequences through a risk assessment matrix.