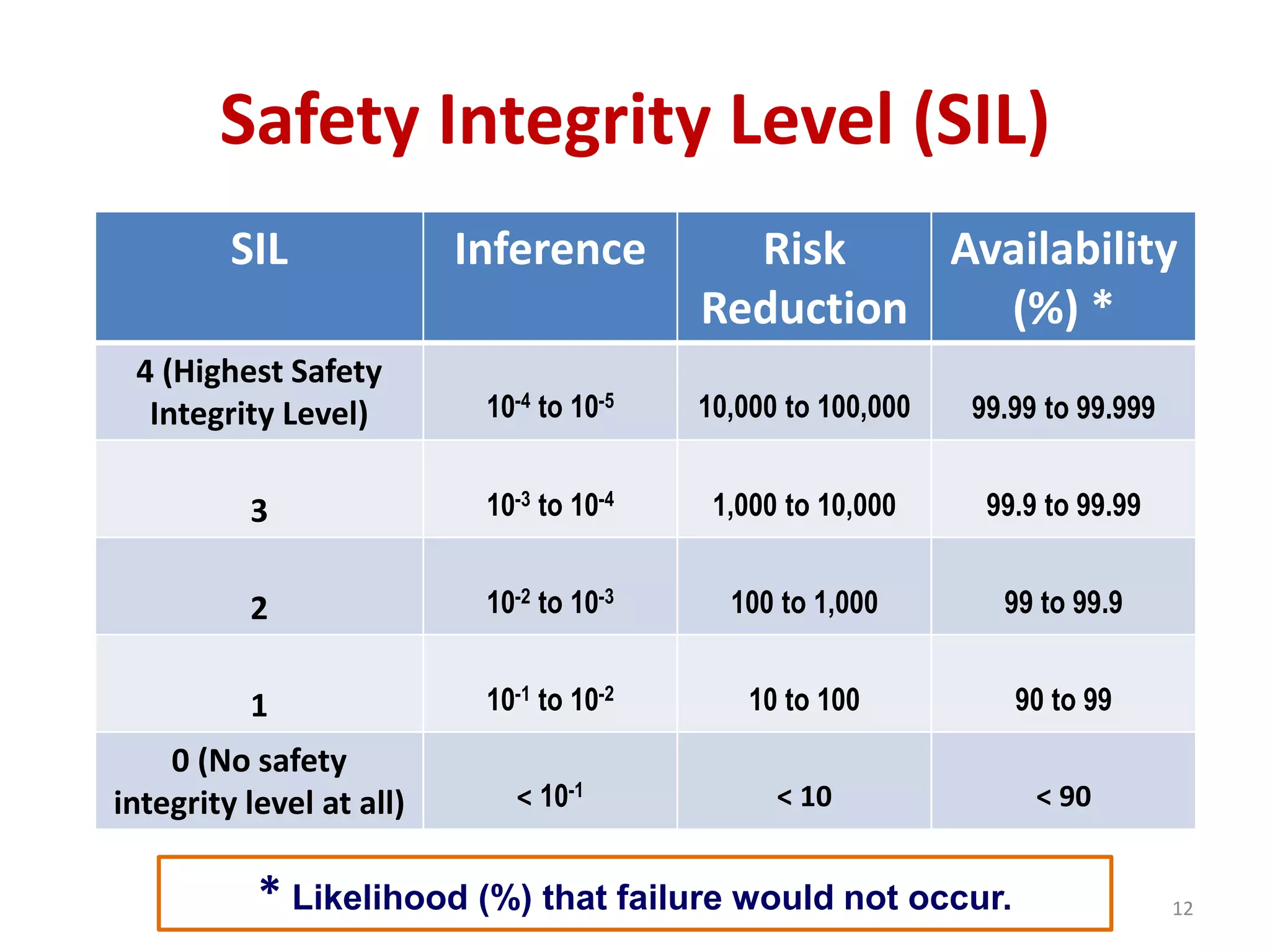

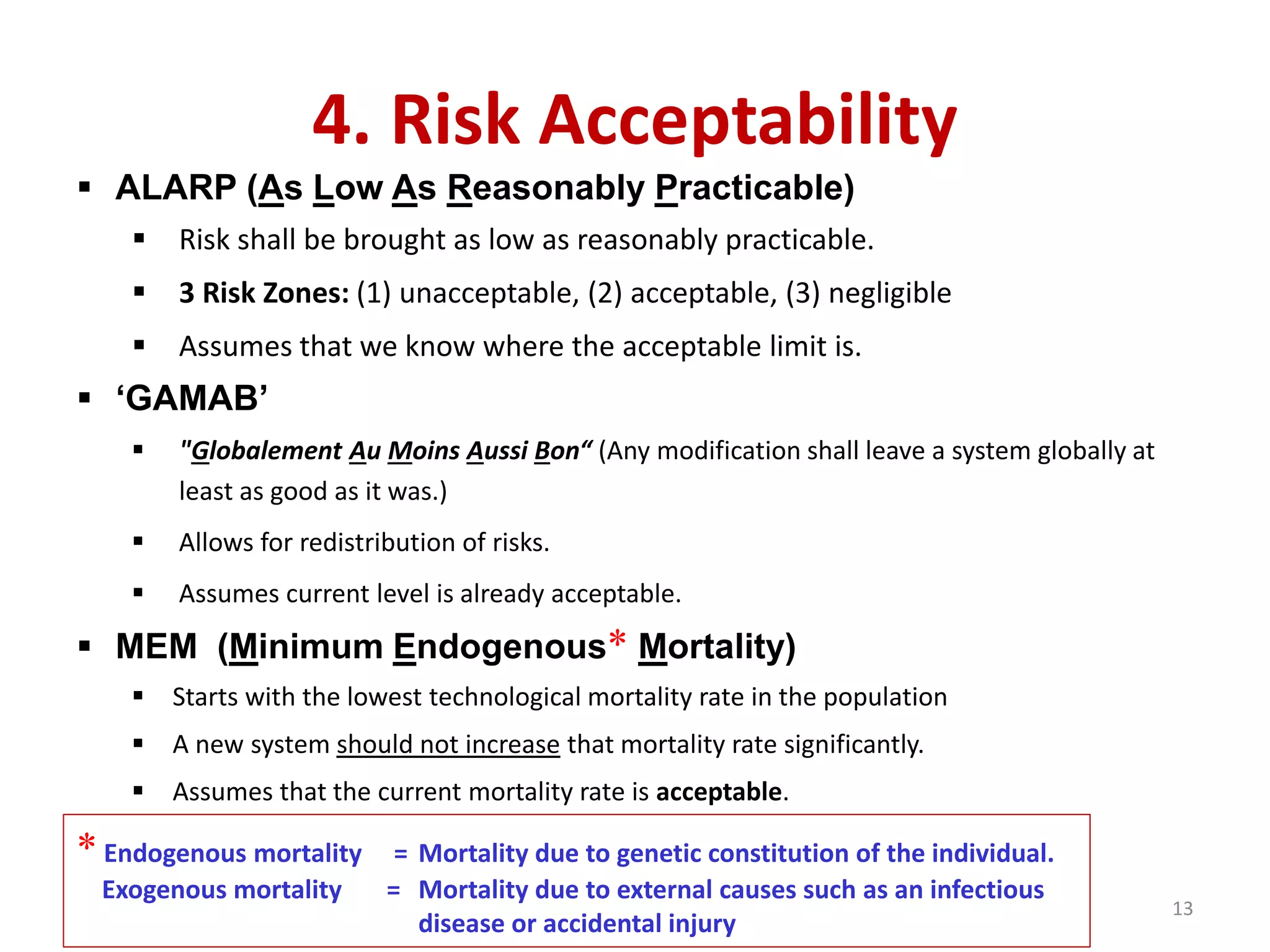

This document discusses safety integrity levels (SILs) which are assigned based on a risk assessment of industrial safety systems. SILs range from 0 to 4, with 4 being the highest level of safety integrity. The document outlines factors that determine a system's SIL such as the number and effectiveness of safety measures implemented. It also discusses challenges in applying SILs such as over-allocating the highest SIL 4 which can be expensive. The document concludes that agreed risk acceptance levels should be used and lower SILs may be sufficient rather than always defaulting to the highest SIL 4 level.