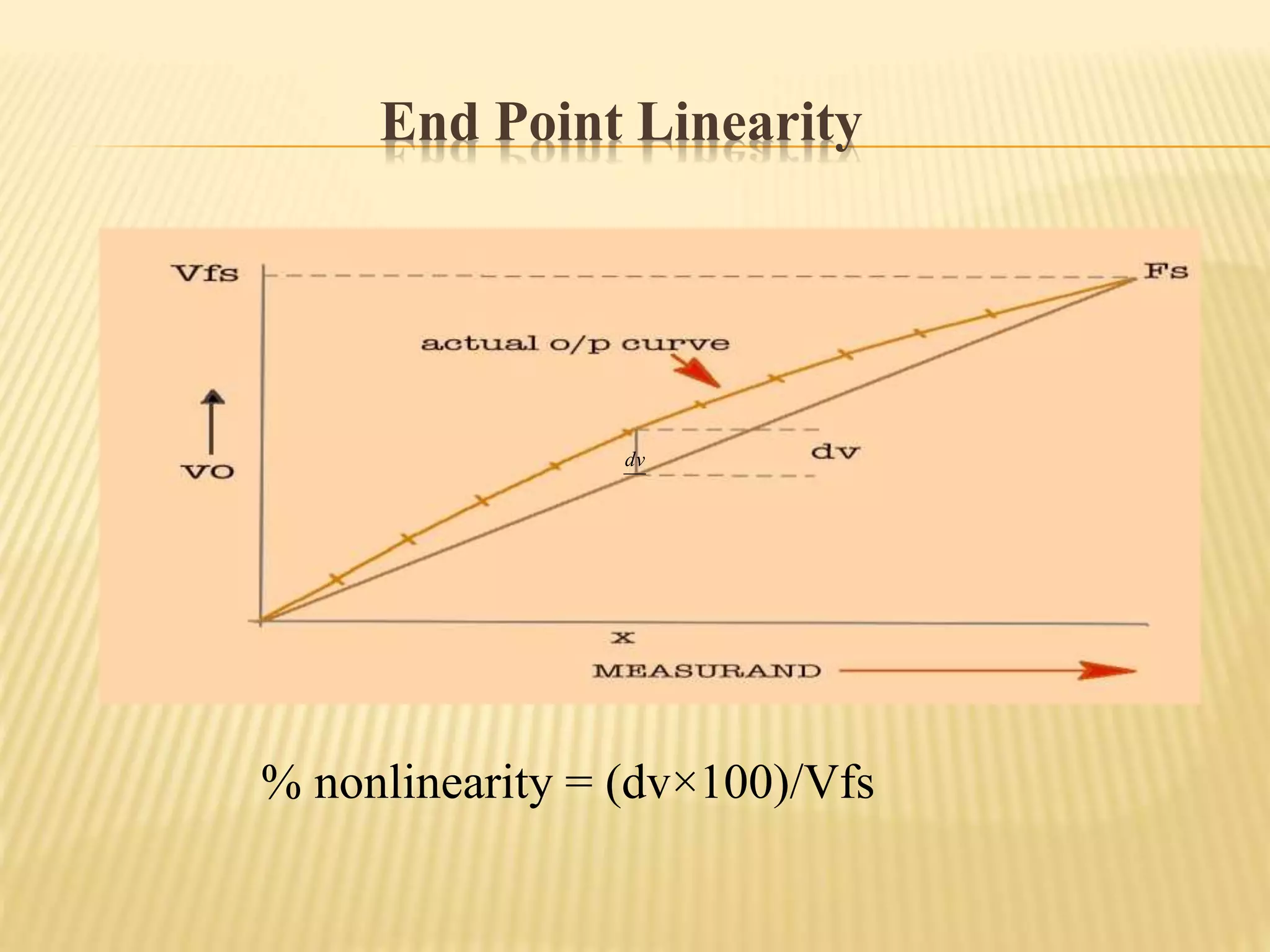

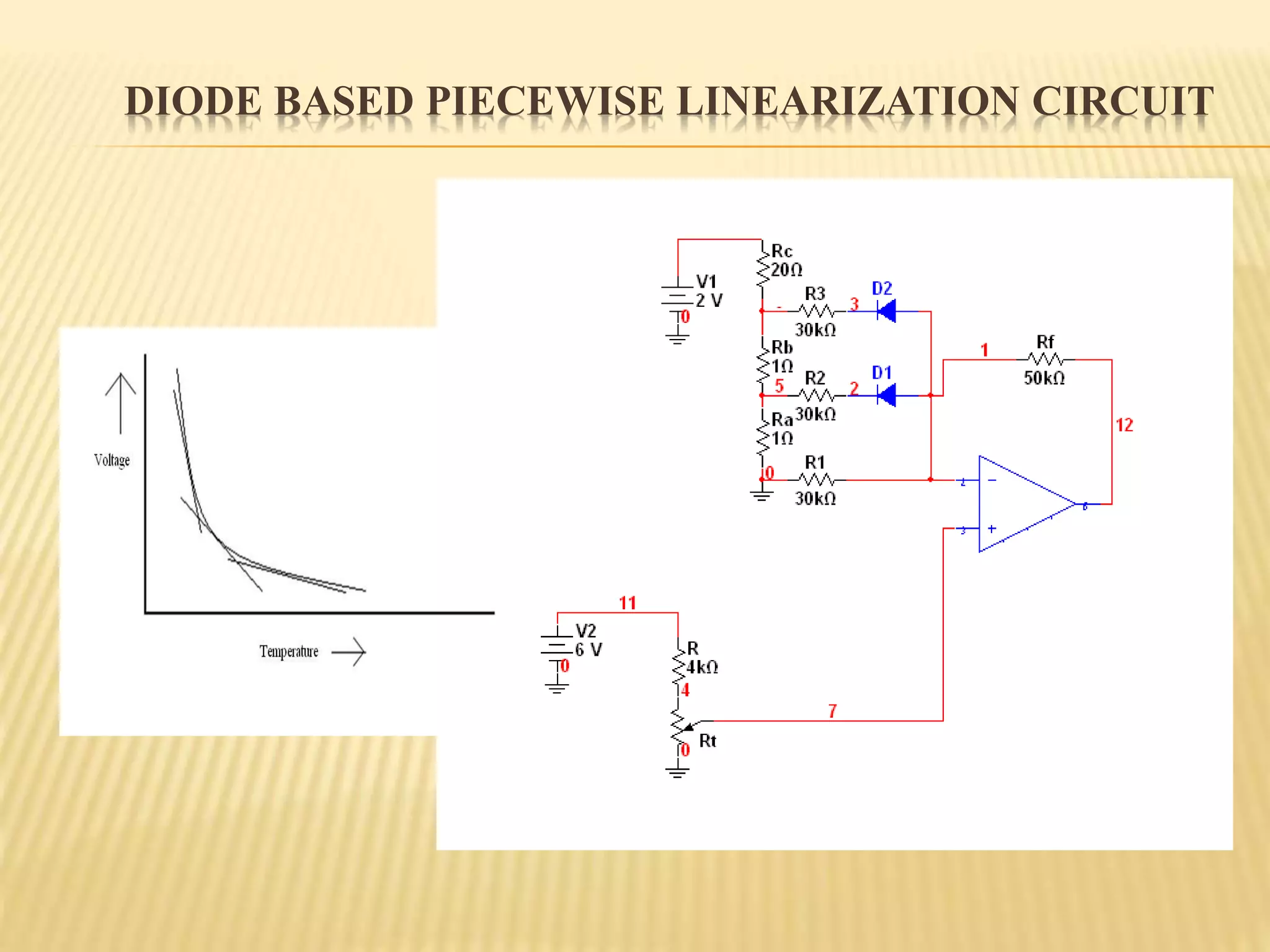

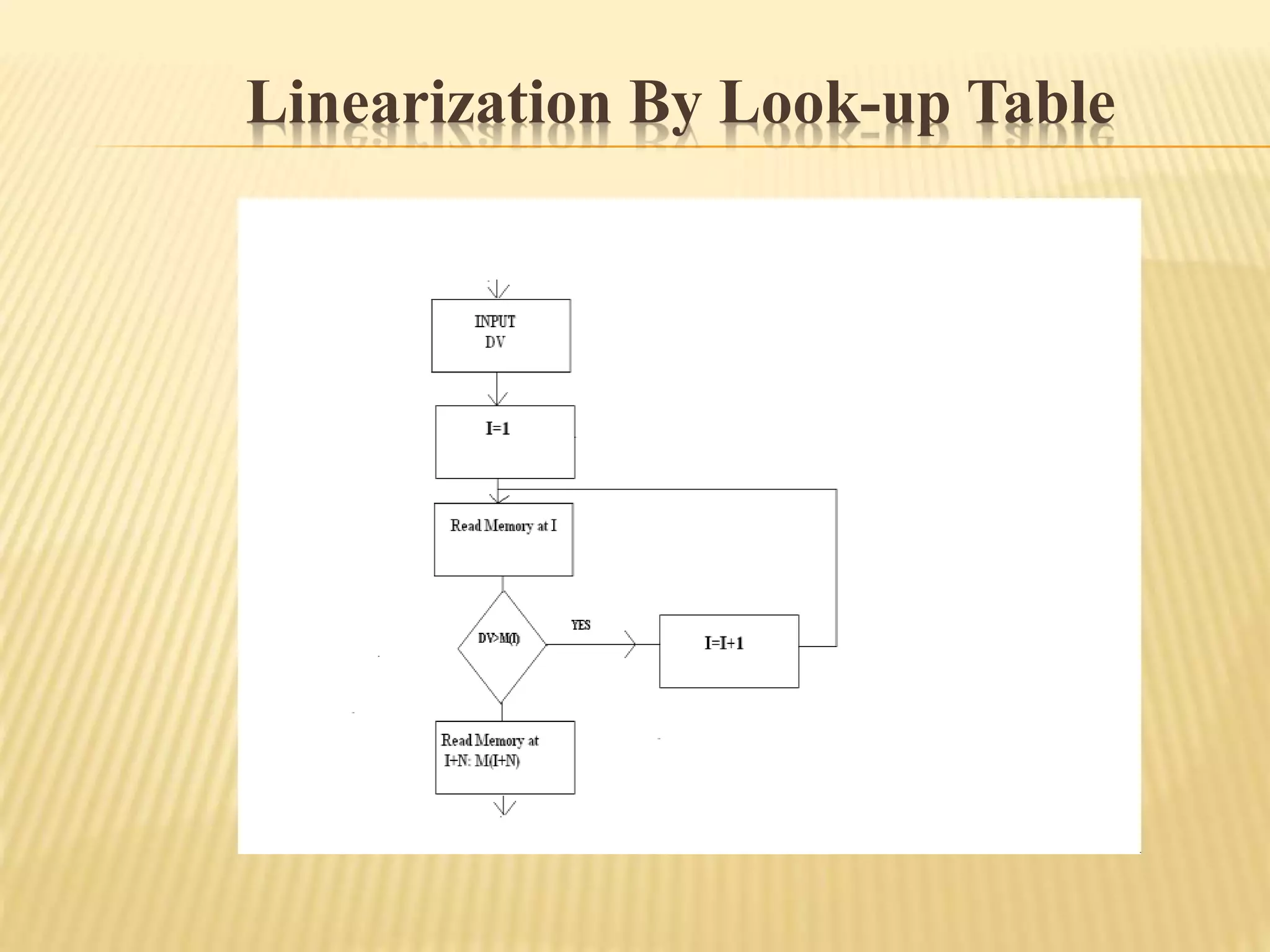

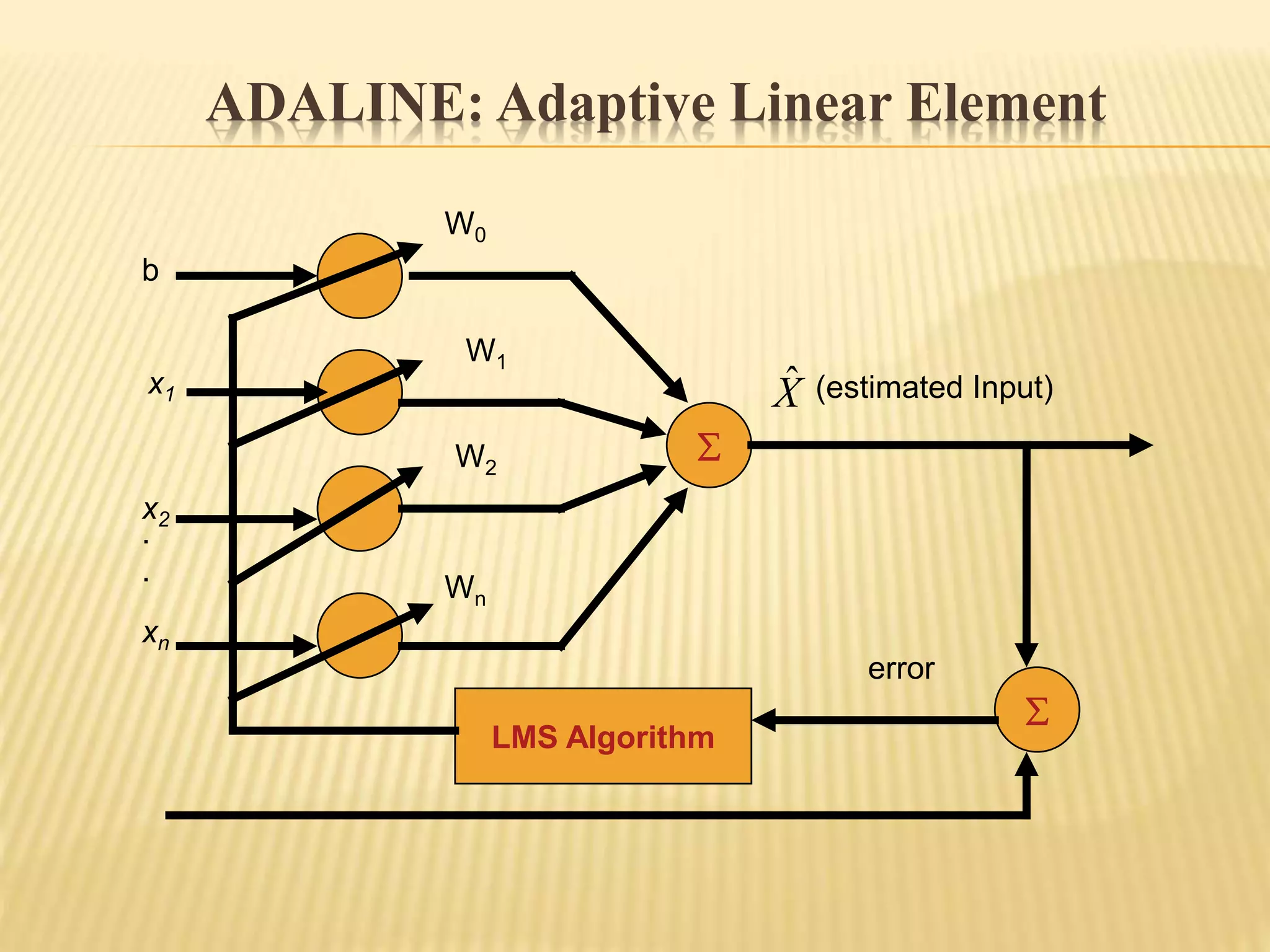

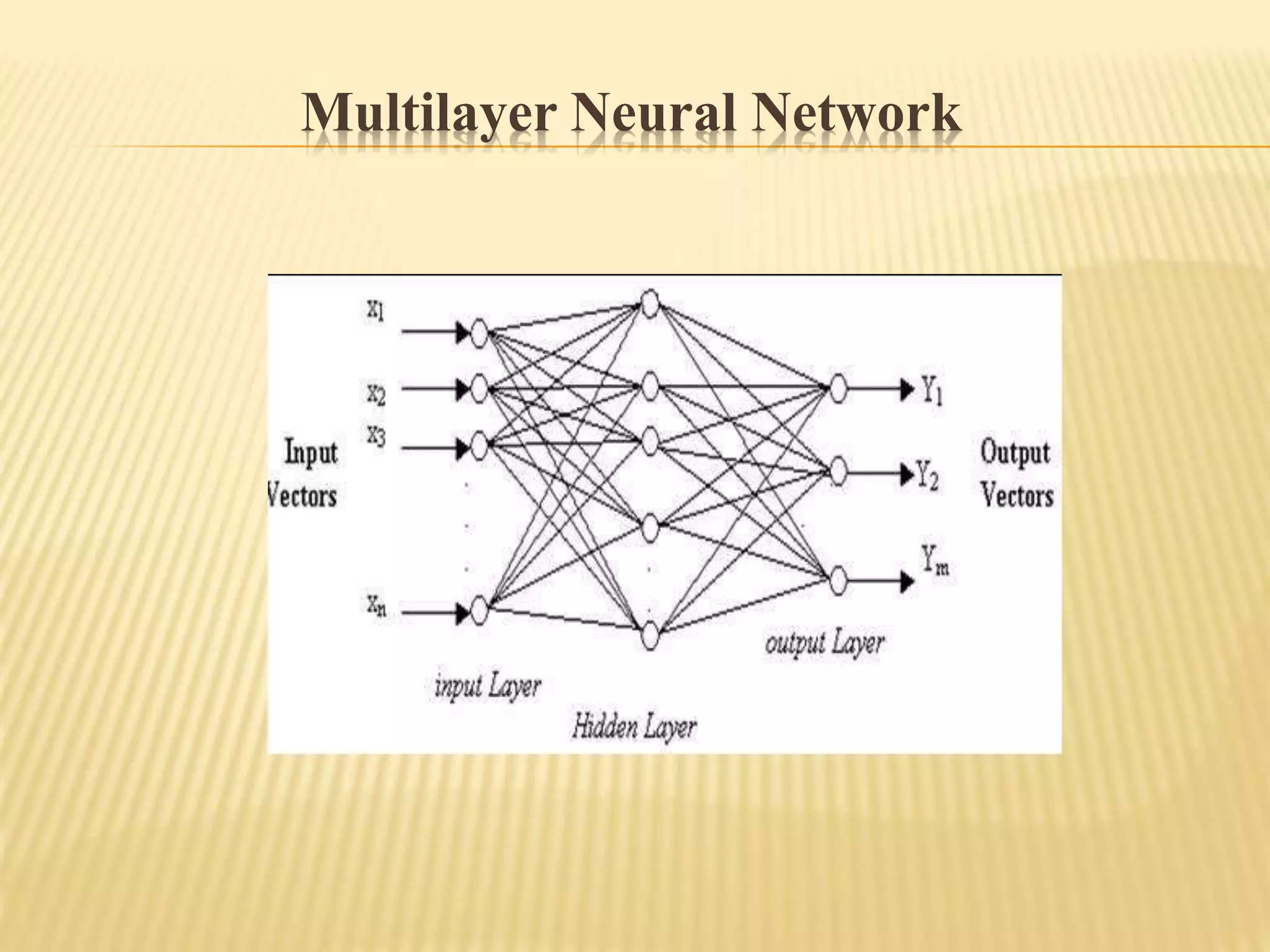

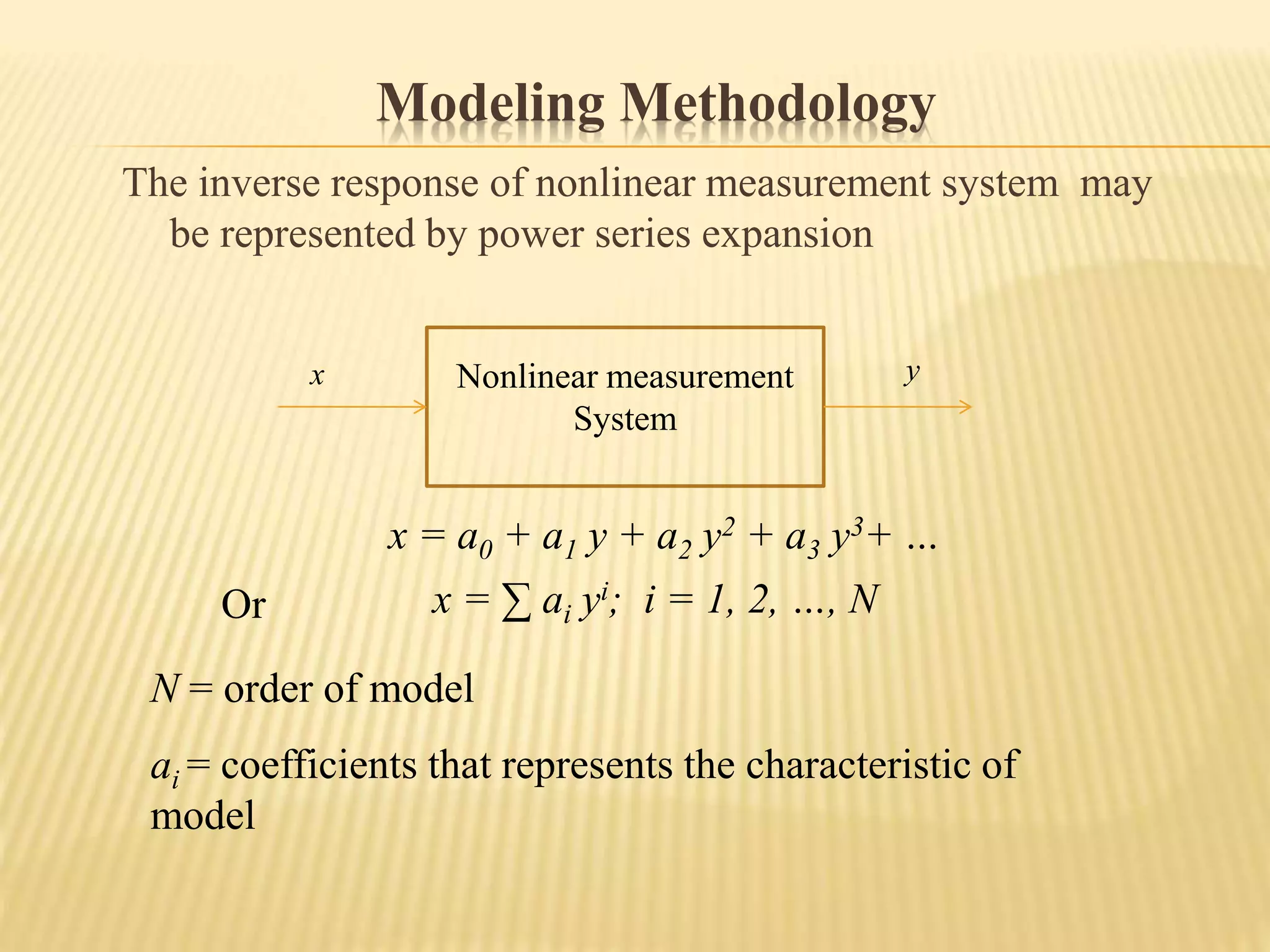

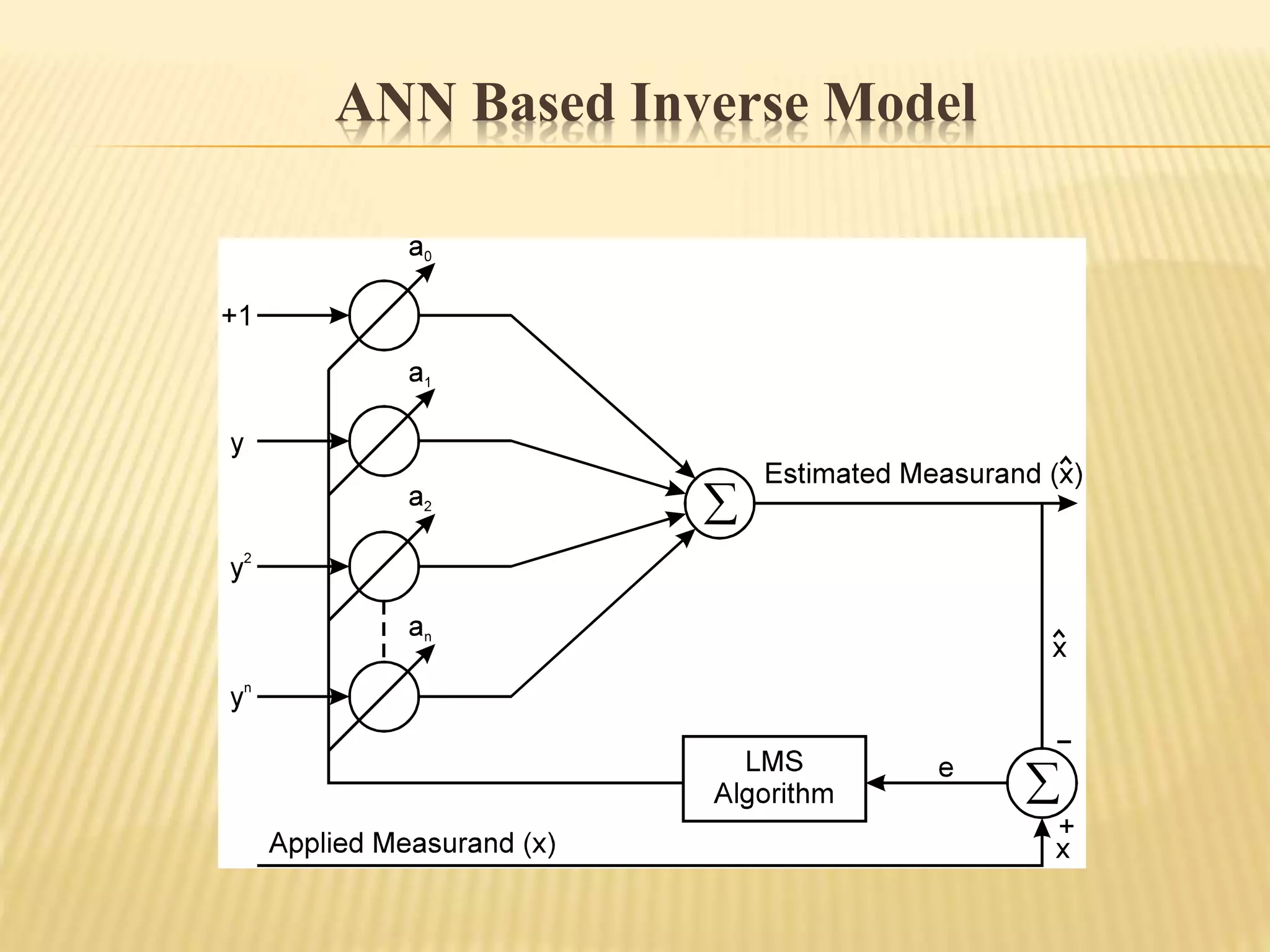

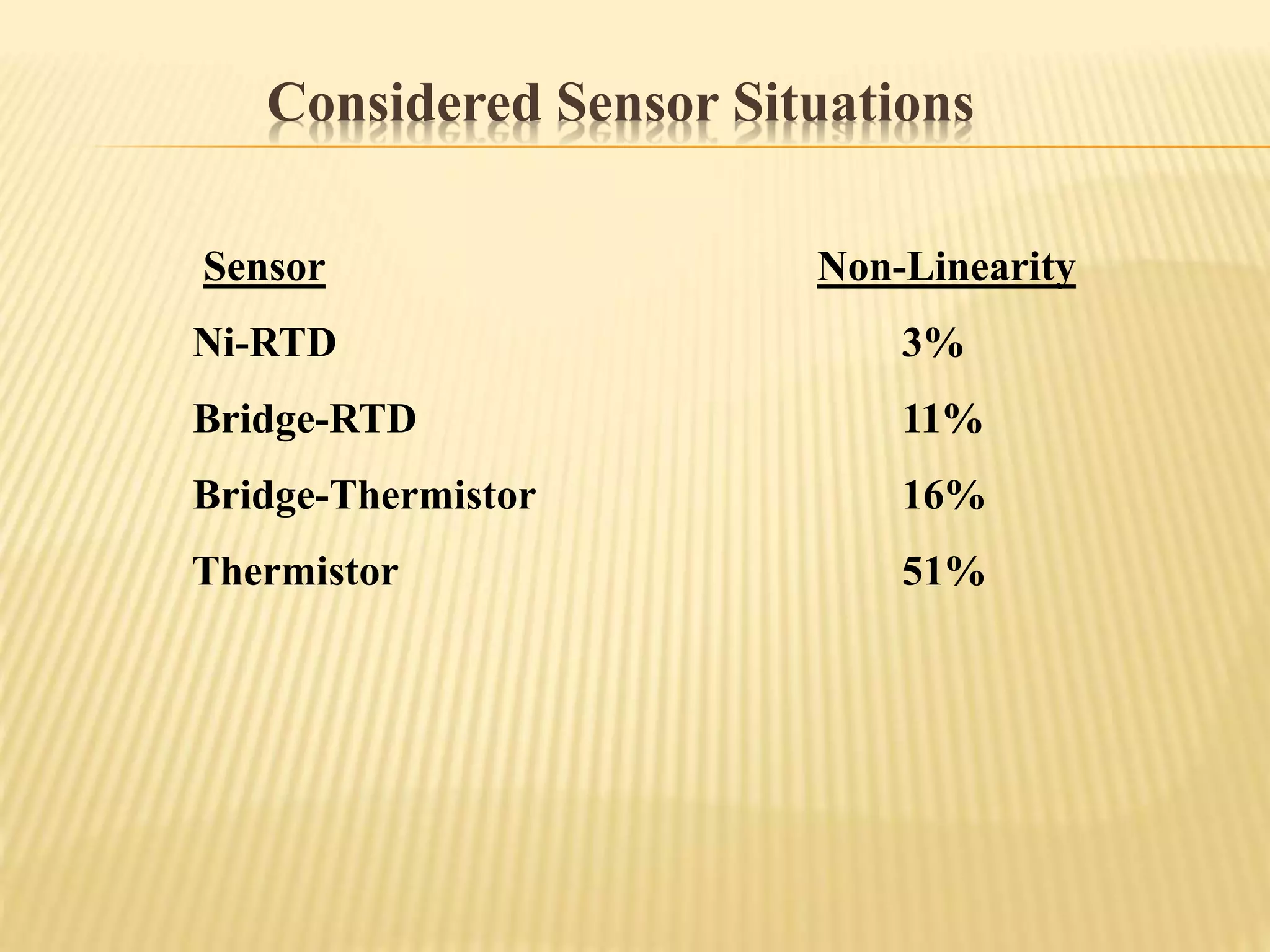

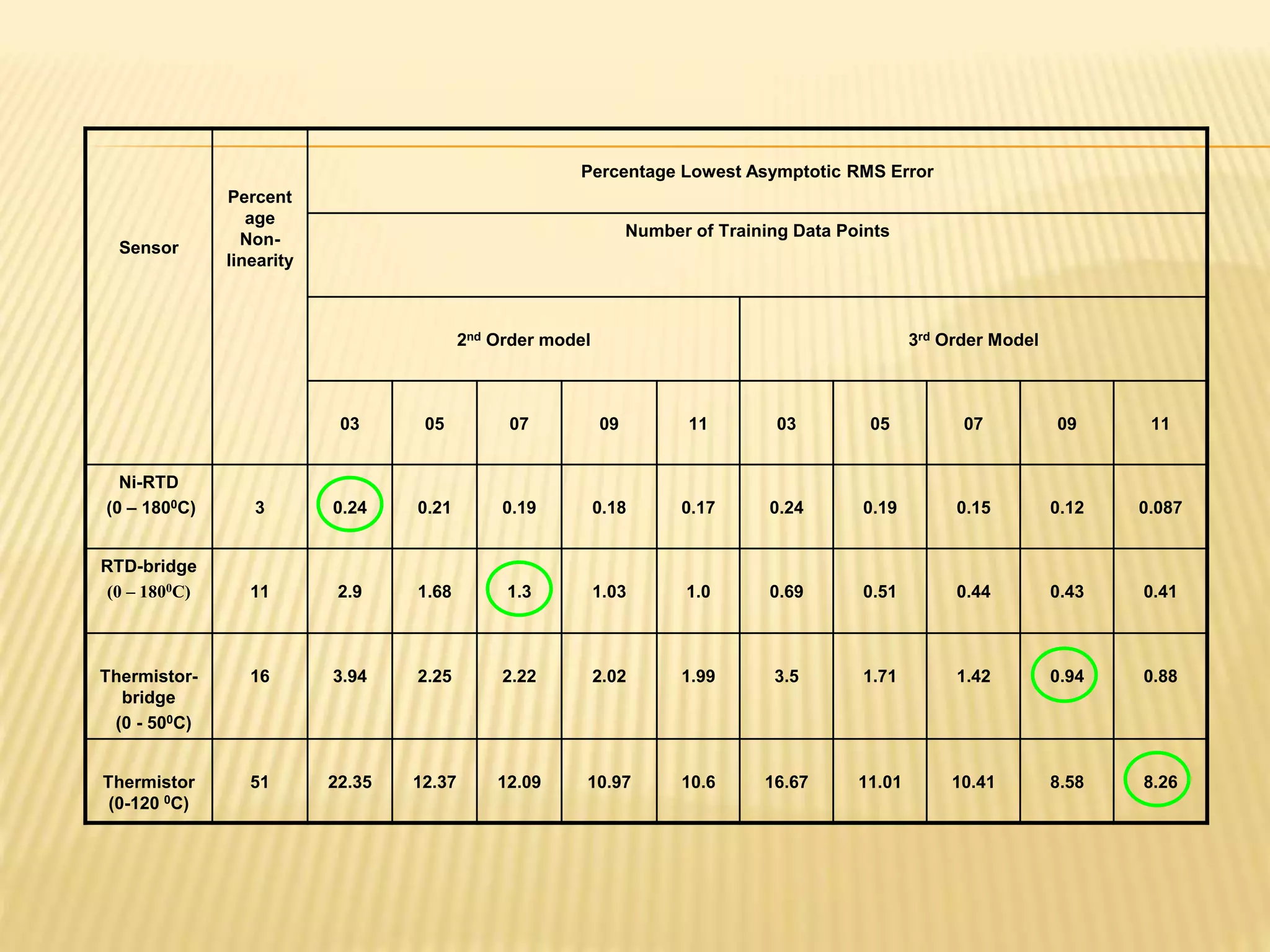

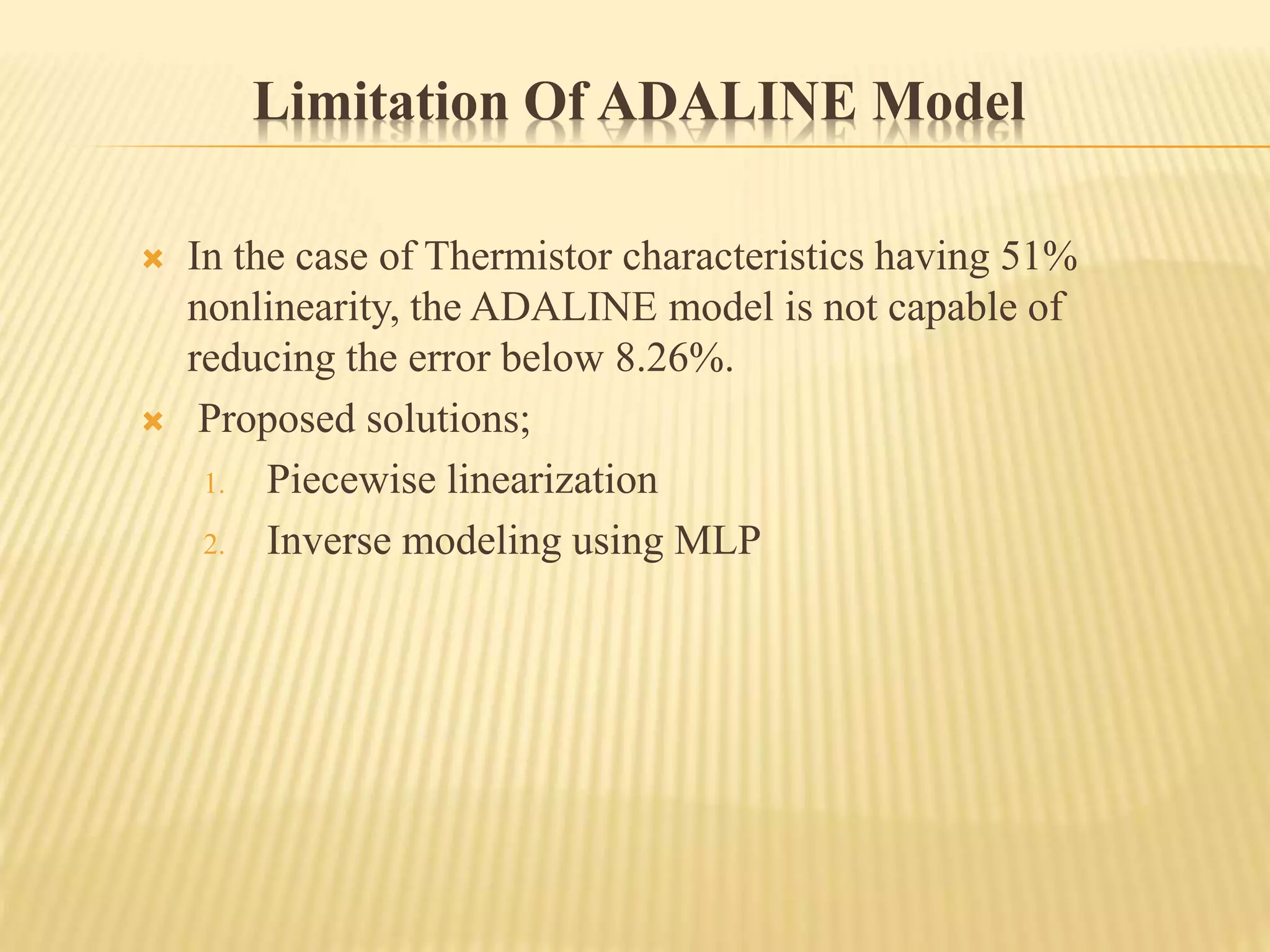

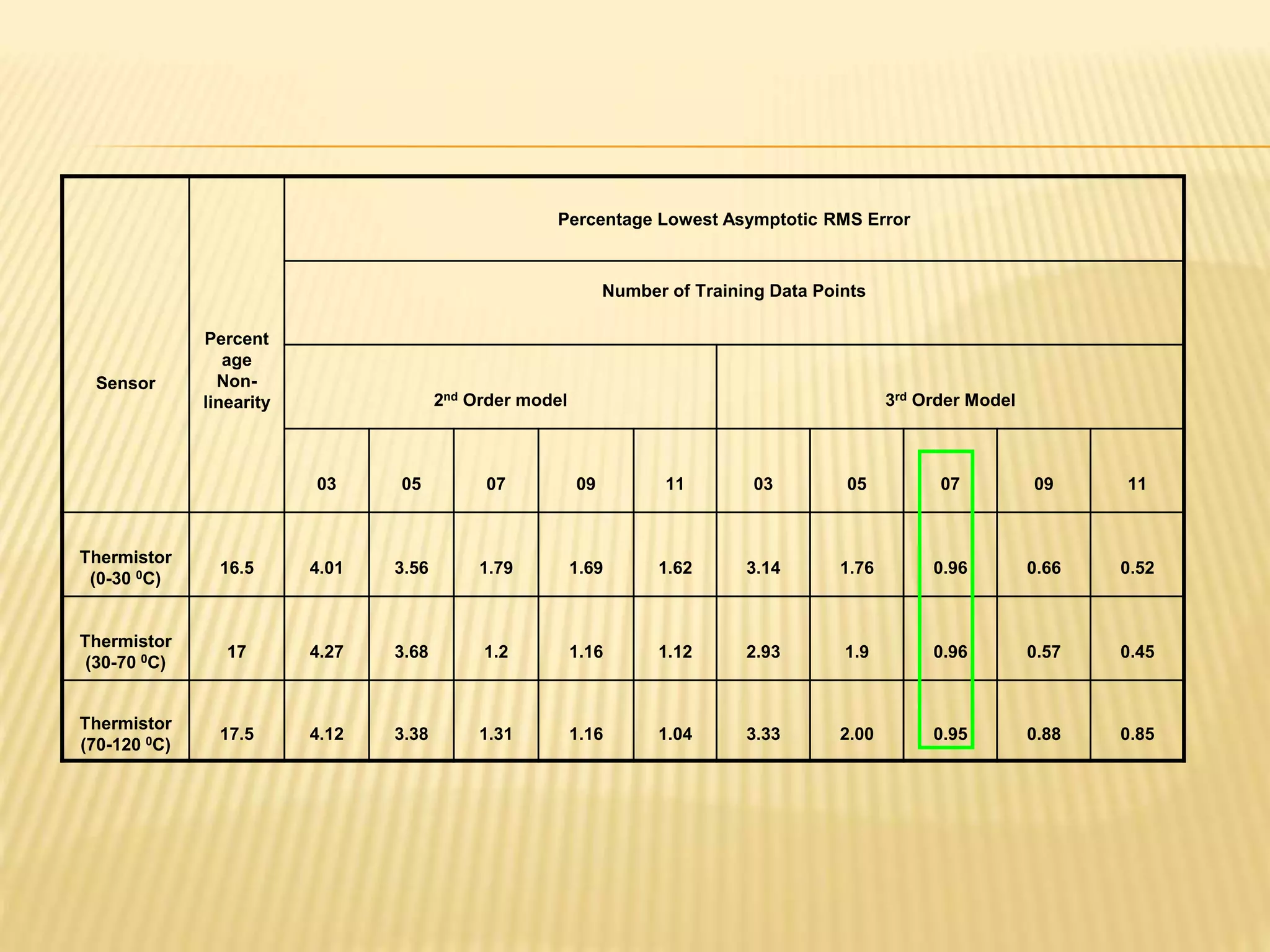

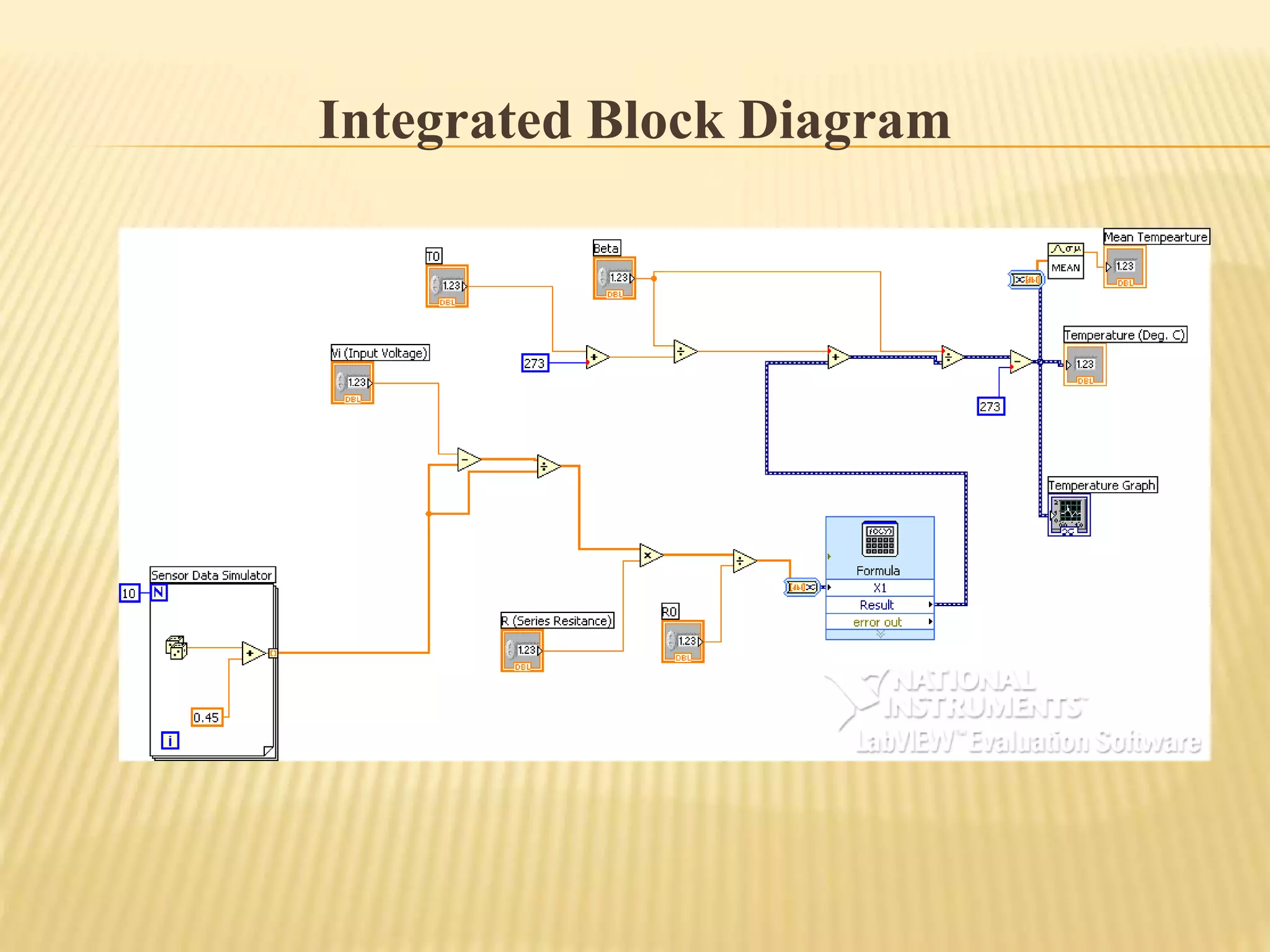

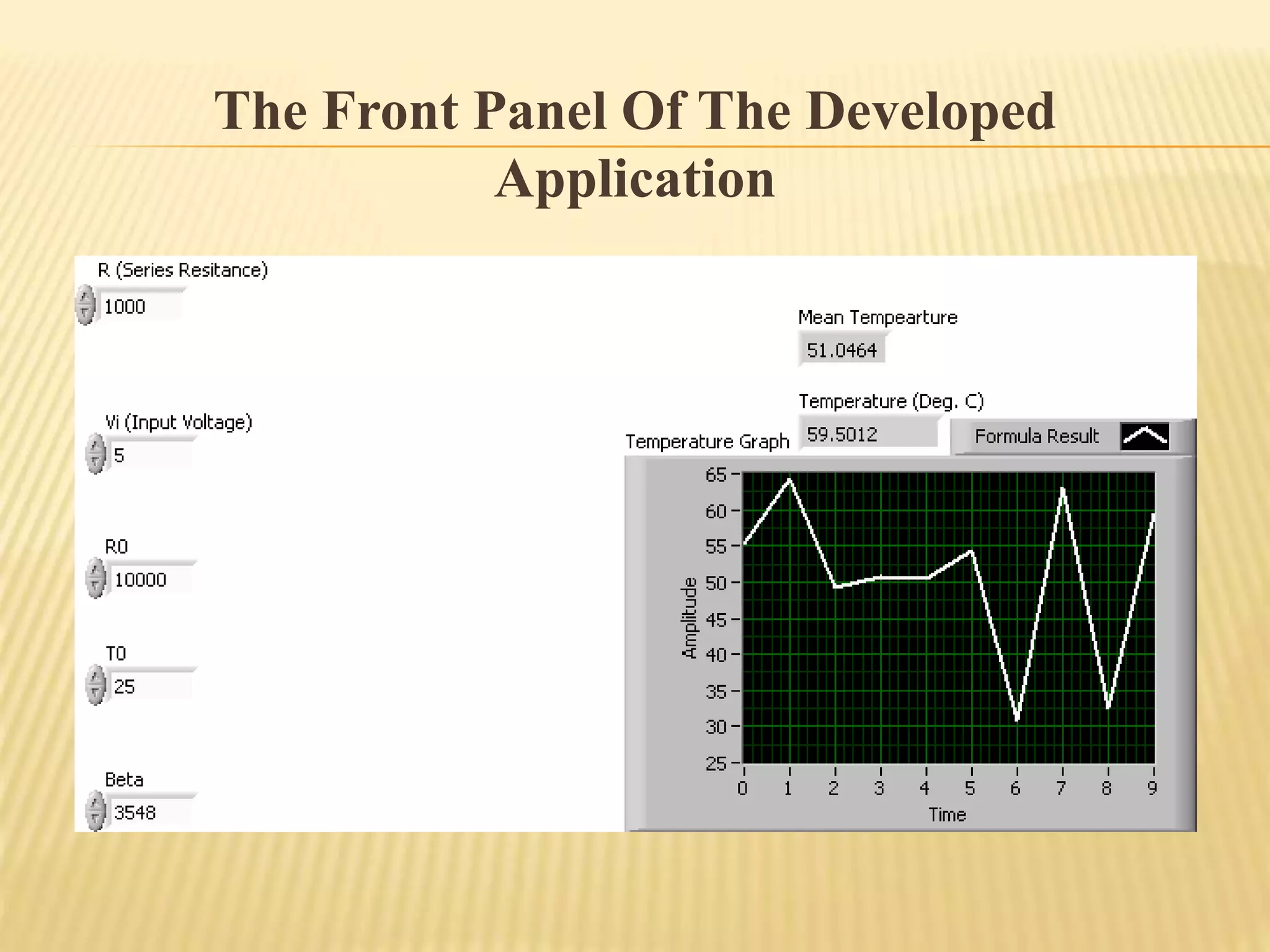

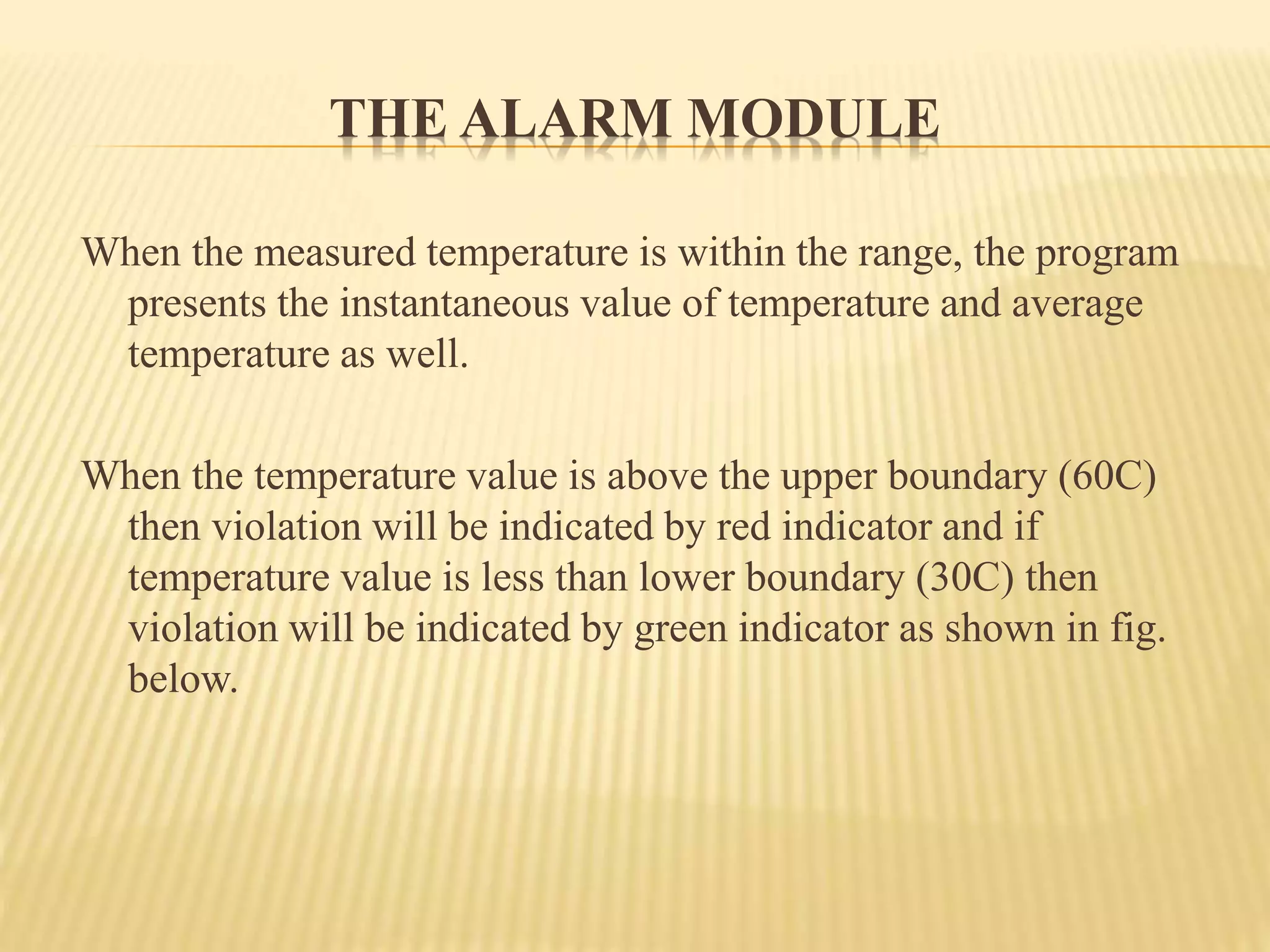

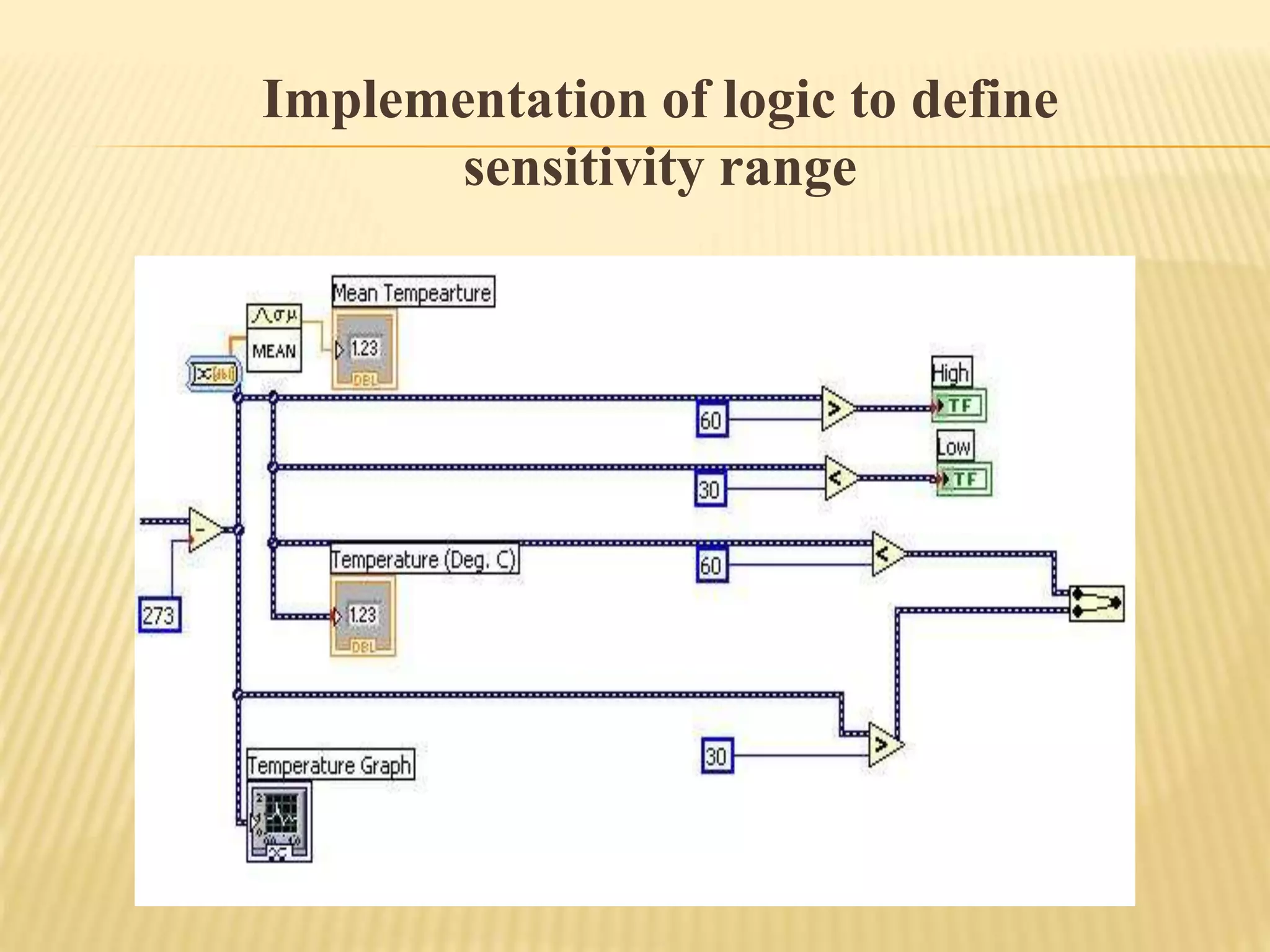

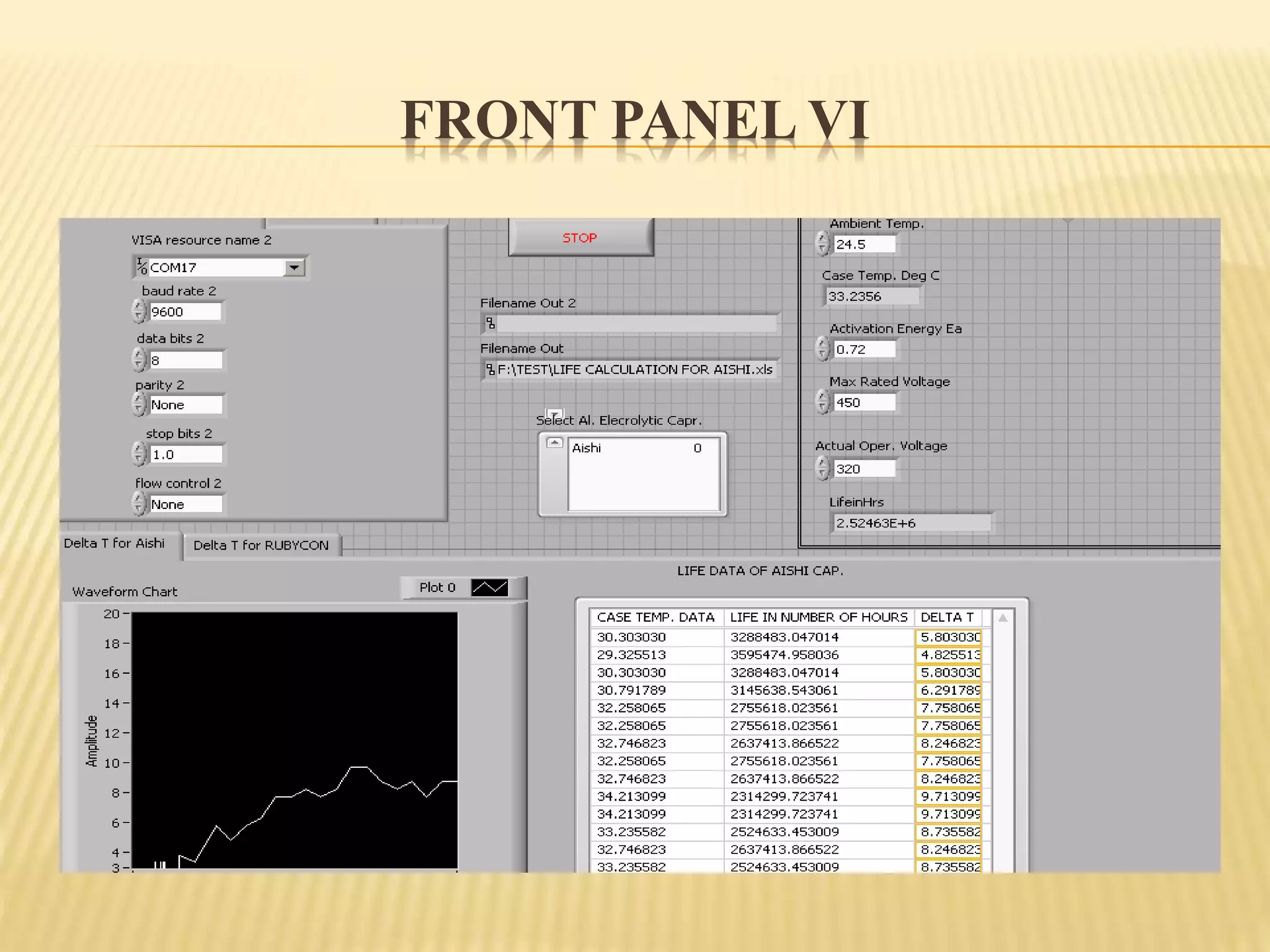

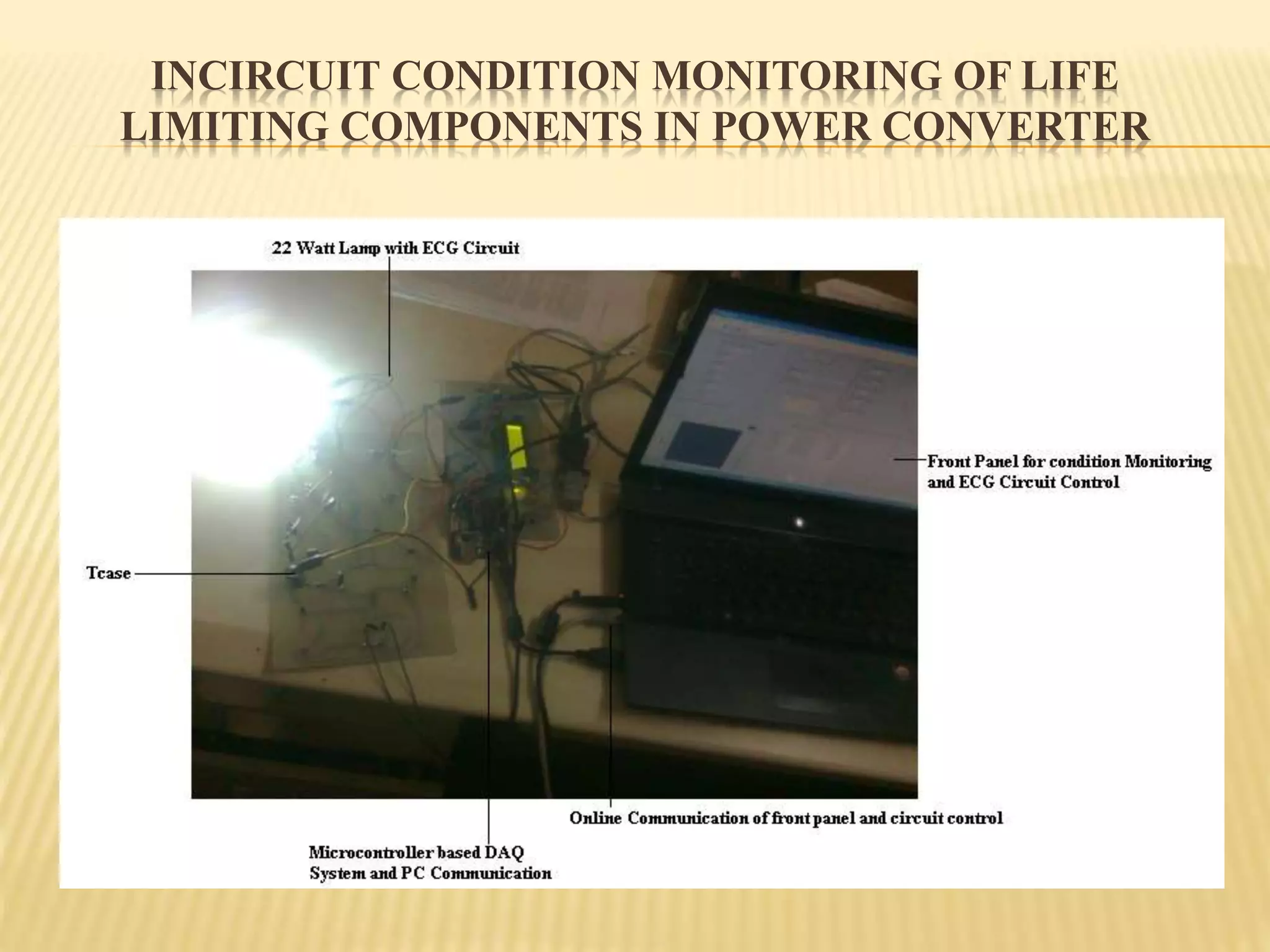

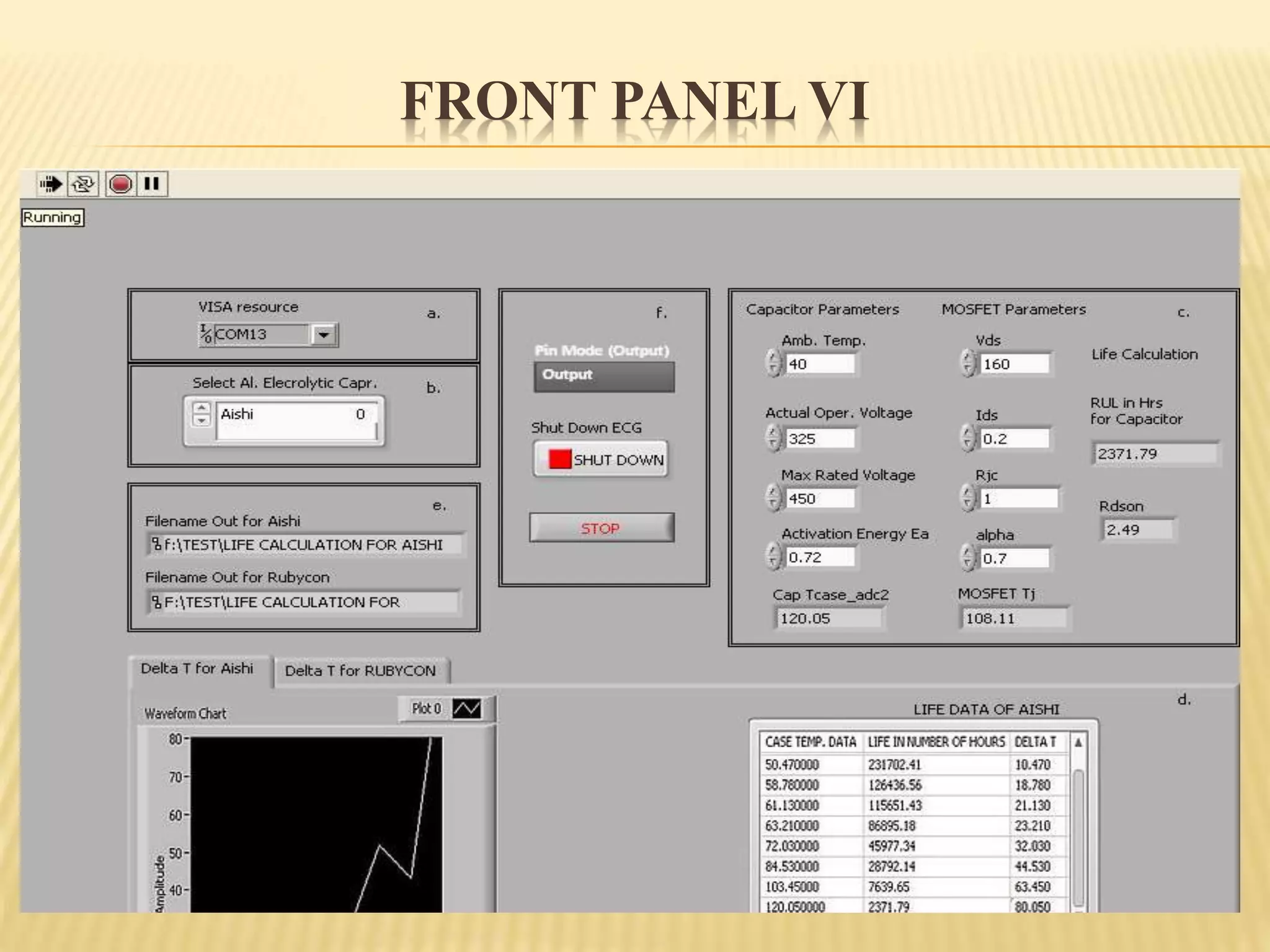

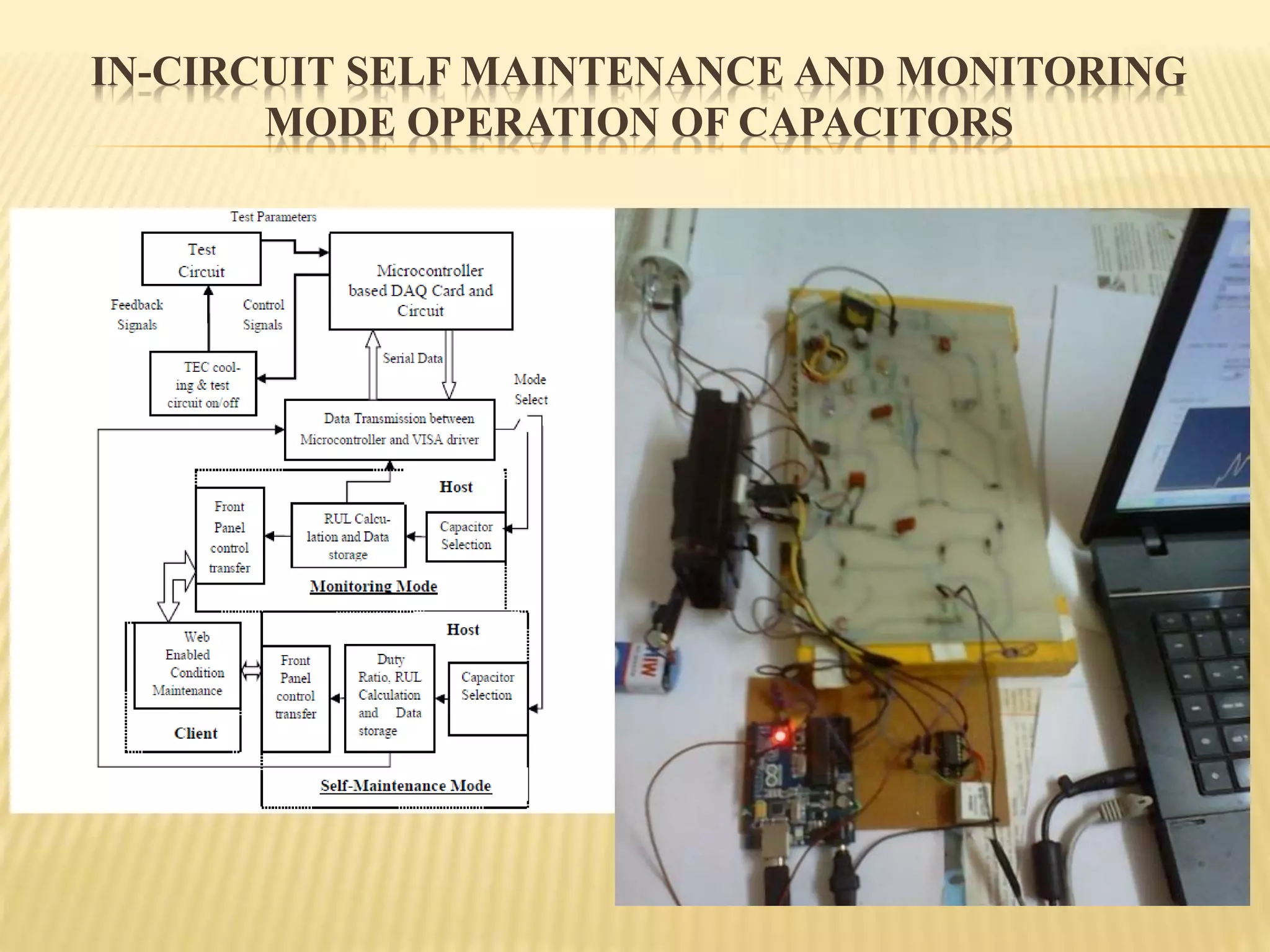

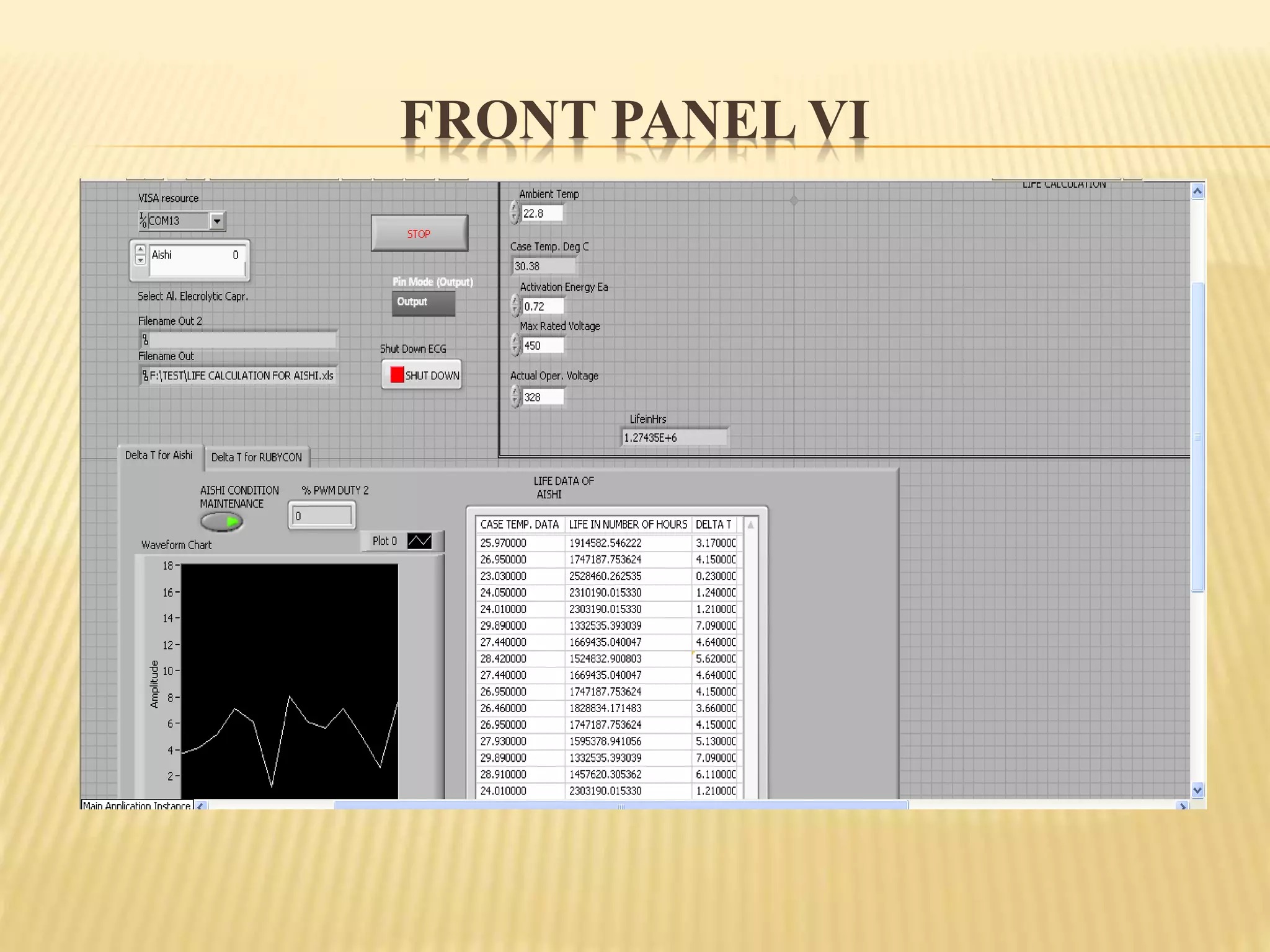

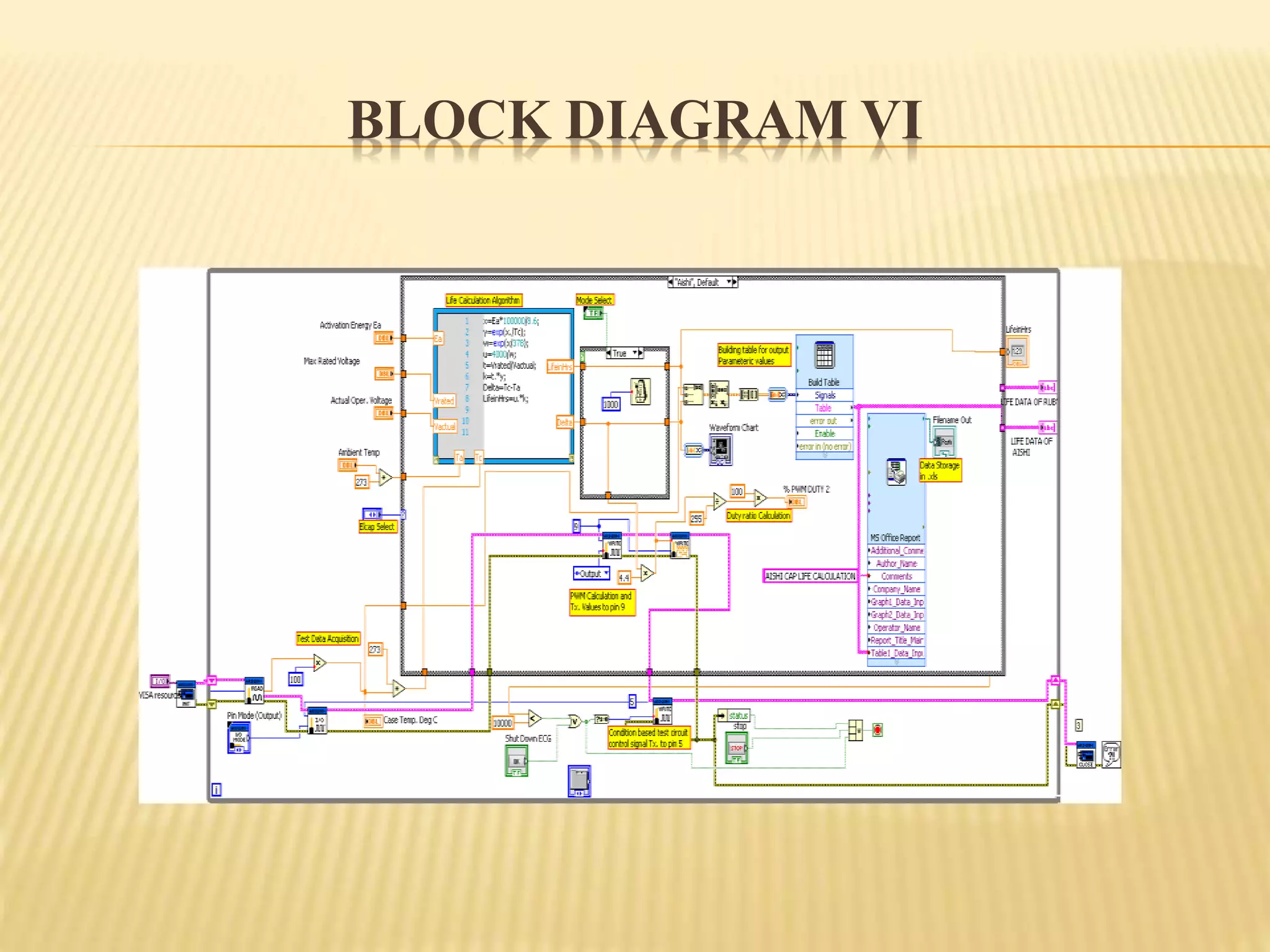

The document outlines methods for signal conditioning and nonlinearity compensation in sensor systems, detailing techniques like piecewise linearization and artificial neural networks (ANNs). It discusses the implementation of a measurement system using MATLAB and LabVIEW for real-time monitoring and self-maintenance of sensors. The conclusion emphasizes a generalized multilayer ANN method for linearization and presents a virtual temperature measurement system alongside condition monitoring practices.

![Linearization By Equation Inversion

Consider a transducer, that converts pressure into voltage as:

V=K [p]^0.5

V is converted into a binary no. by ADC.

DV varies as [p]^0.5.

Squaring this DV

p varies as DV*DV

Thus a program would input a sample DV and multiply it by

itself.](https://image.slidesharecdn.com/prof-150901074550-lva1-app6891/75/Signal-conditioning-condition-monitoring-using-LabView-by-Prof-shakeb-ahmad-khan-14-2048.jpg)

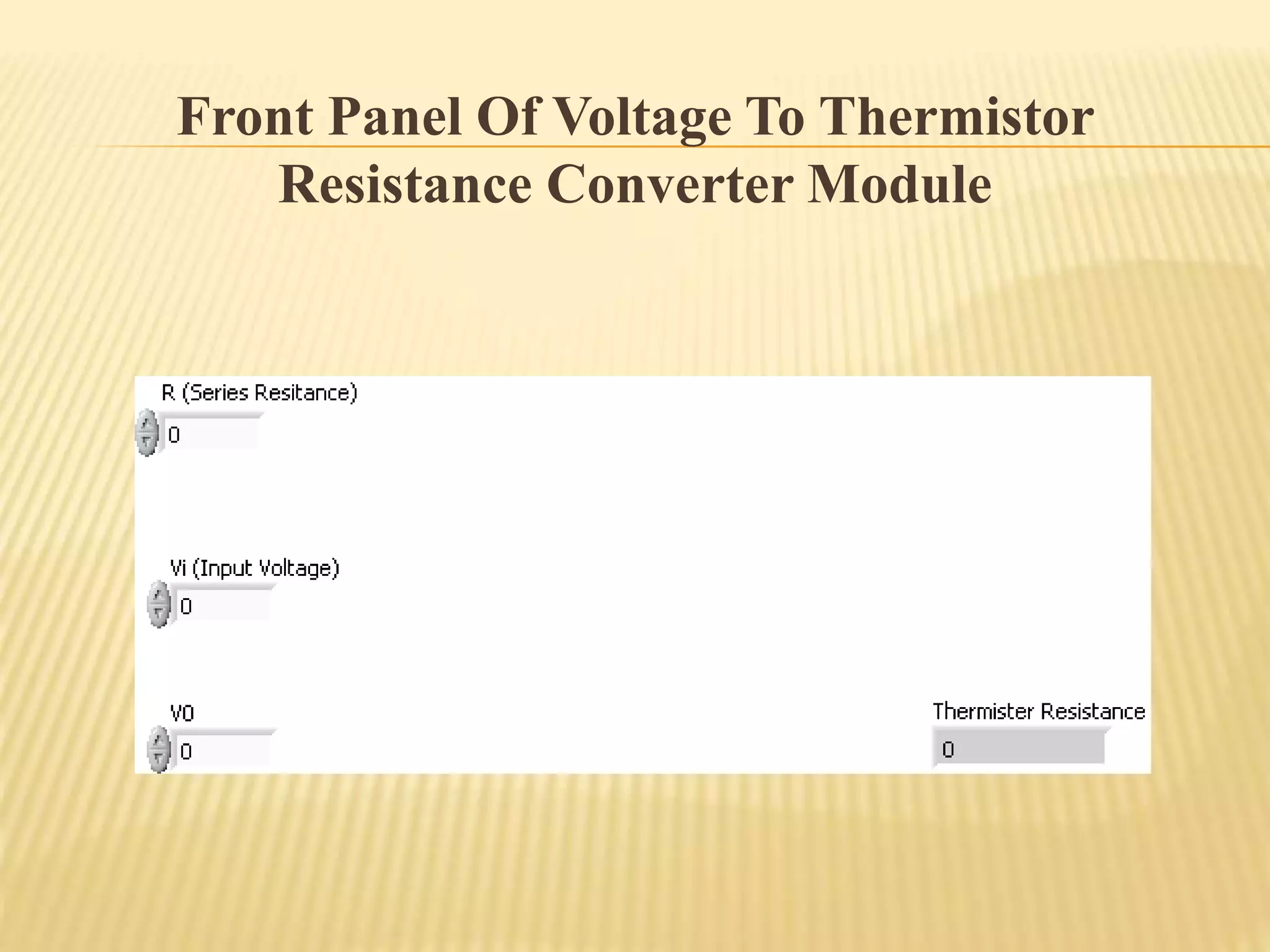

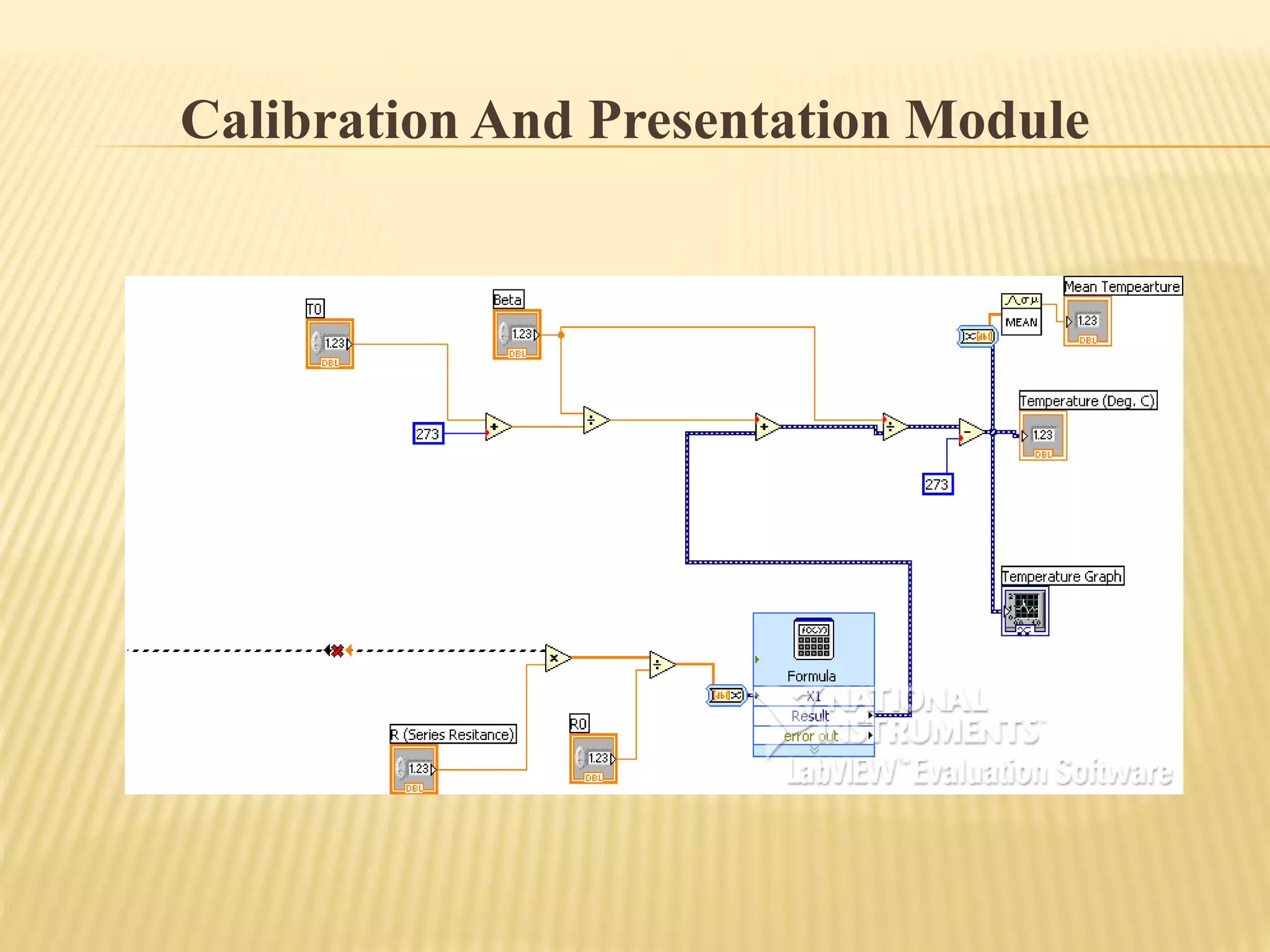

![Calibration And Presentation Module

The calibration module implements following expression:-

T = /[{ln(Rth/ R0)}+ /T0]

Where

Rth Thermistor resistance at T (K)

T Thermistor temperature (K)

R0 Resistance at T0 (K)

Thermistor characteristics constant (K)](https://image.slidesharecdn.com/prof-150901074550-lva1-app6891/75/Signal-conditioning-condition-monitoring-using-LabView-by-Prof-shakeb-ahmad-khan-41-2048.jpg)

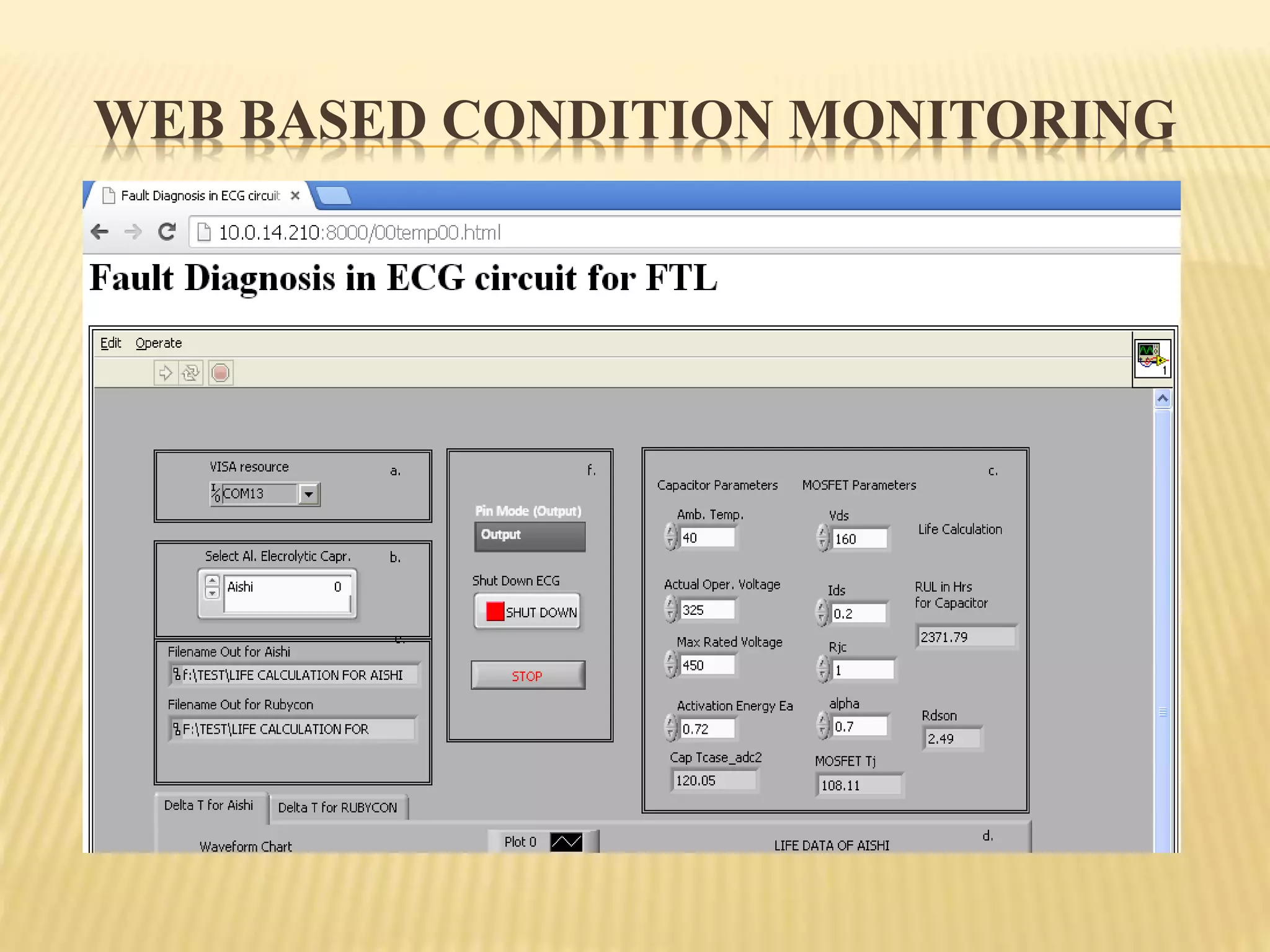

![WEB BASED CONDITION MONITORING

[MONITORING MODE]](https://image.slidesharecdn.com/prof-150901074550-lva1-app6891/75/Signal-conditioning-condition-monitoring-using-LabView-by-Prof-shakeb-ahmad-khan-57-2048.jpg)

![WEB BASED CONDITION MONITORING [SELF

MAINTENANCE MODE]](https://image.slidesharecdn.com/prof-150901074550-lva1-app6891/75/Signal-conditioning-condition-monitoring-using-LabView-by-Prof-shakeb-ahmad-khan-58-2048.jpg)