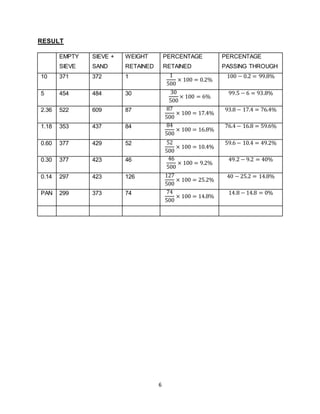

This document summarizes a sieve test experiment conducted on fine aggregate to determine its grain size distribution. The experiment involved sieving 500g of dry fine aggregate through various sized sieves, weighing the material retained on each sieve, and calculating the percentage passing and retained. The results were plotted on a grading curve and compared to BS standards to evaluate the quality of the aggregate sample. In conclusion, the experiment was successfully performed and the fineness modulus calculated. The aggregate sample fell within the acceptable range specified by standards.