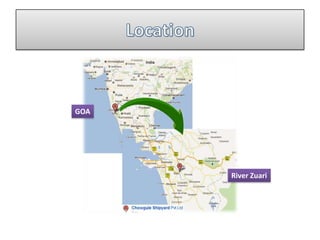

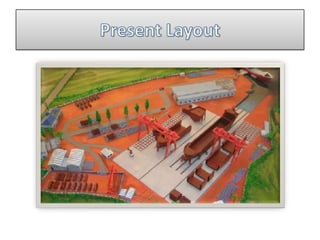

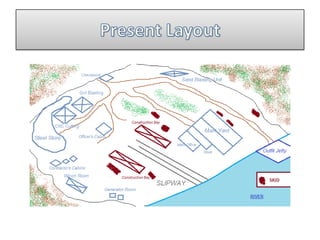

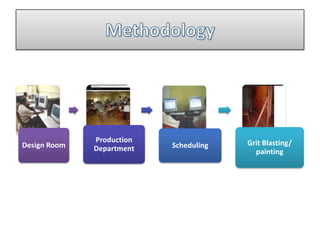

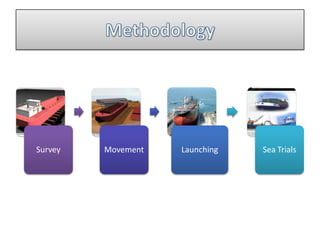

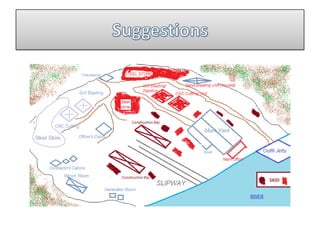

Chowgule & Co. Ltd.'s shipbuilding division, established in 1951, focuses on building and repairing small vessels, primarily for iron ore transport and fishing. The document outlines proposed layout improvements to enhance production efficiency and reduce delivery times, including relocating certain facilities and optimizing material flow. Current limitations in space and a lack of government support necessitate these changes to expand product offerings and maintain competitiveness.