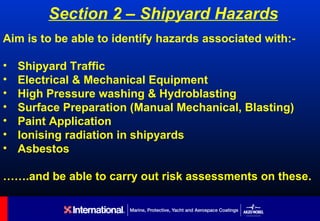

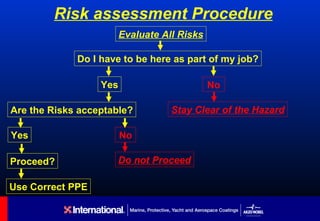

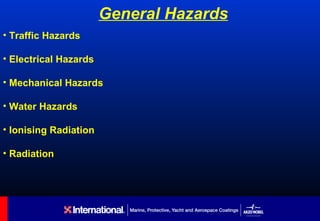

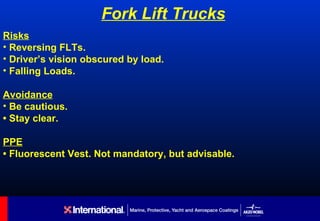

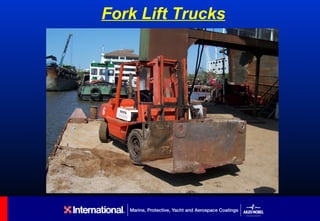

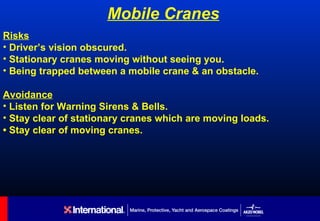

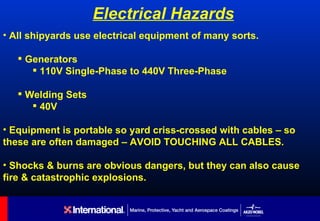

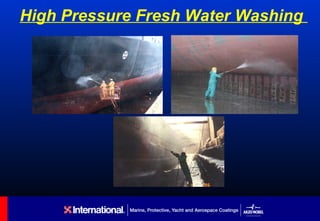

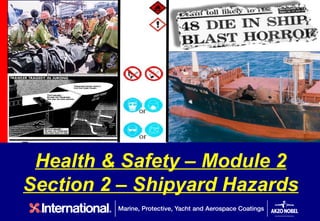

This document provides an overview of common hazards found in shipyards and guidance on risk assessment. It identifies key shipyard hazards such as traffic, electrical equipment, water hazards, and asbestos. For each hazard, it describes potential risks and recommendations to avoid risks, including staying clear of hazards, using proper personal protective equipment, and following safety procedures. The document emphasizes that shipyards can be dangerous places and accidents are common due to a general lack of safety culture, so risk assessment and caution are important to prevent injuries.