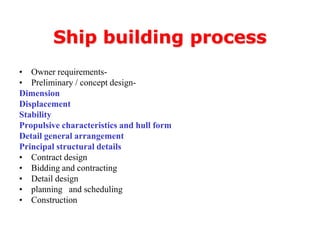

This document provides an overview of ship construction and outlines a 7-week course on the topic. It will cover ship structure, types of ships, construction processes, regulatory bodies, and key components. Students will learn about structural members, terminology, and framing systems. The document lists learning objectives and navigation for the course, which will cover construction overview, the construction process, ship dimensions and forms, development of ship types, ship structure, outfitting, and a final assignment project.