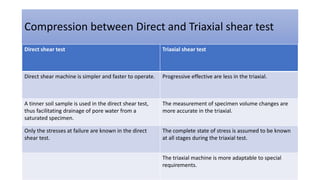

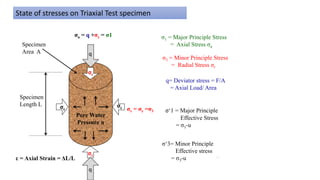

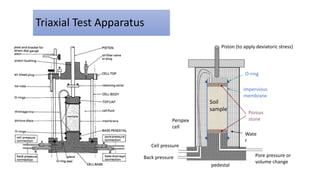

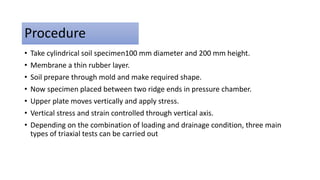

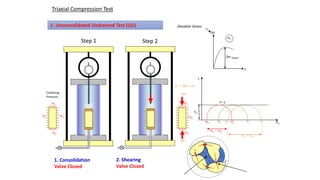

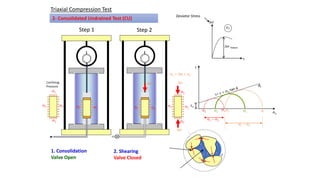

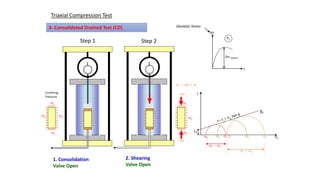

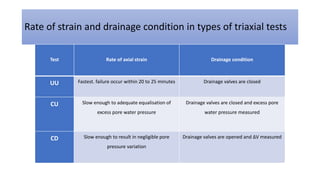

The document discusses shear strength of soils and describes the triaxial shear test. It explains that the triaxial test subjects a soil specimen to three compressive stresses in perpendicular directions to measure its mechanical properties. Direct shear and triaxial tests are described and compared. The triaxial test apparatus and procedures for unconsolidated-undrained, consolidated-undrained, and consolidated-drained triaxial tests are outlined. Advancements in triaxial testing options and conclusions on benefits of the triaxial test are presented.