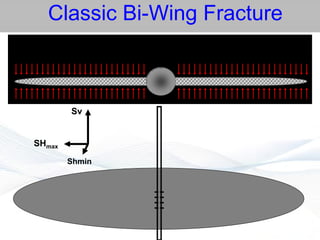

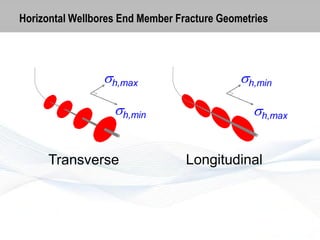

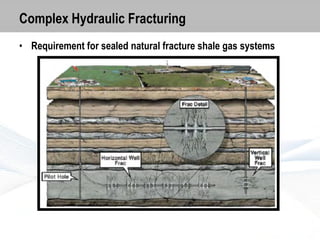

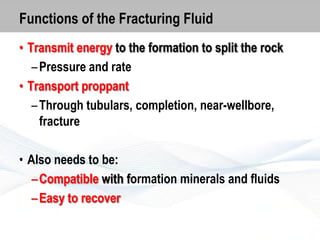

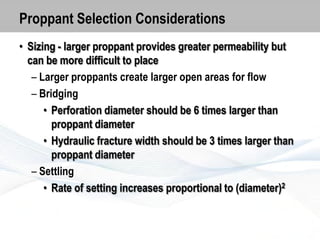

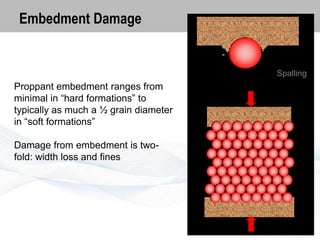

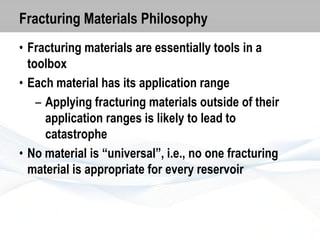

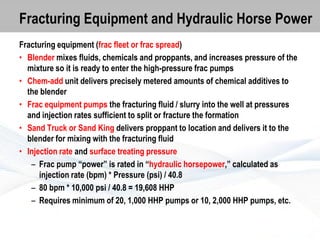

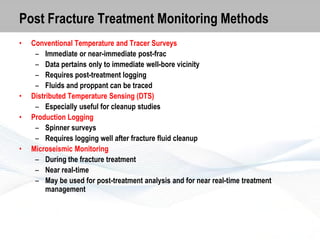

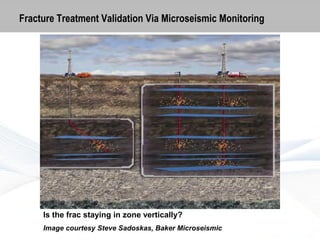

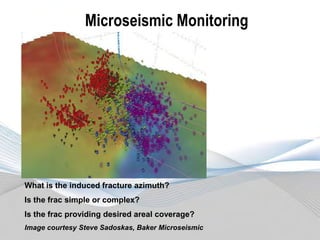

Hydraulic fracturing is necessary to produce economic quantities of gas from shale reservoirs with very low permeability. Complex fracture geometry is important to maximize contact between the fracture and reservoir. The fracturing process involves pumping fluid to create fractures, then a slurry of proppant to prop open the fractures. Proppant and fluid selection depends on factors like embedment and closure stress. While aspects like rate, volume, and proppant quantity can be controlled, the natural variations in shale make the exact fracture geometry and productivity impacts difficult to predict. Monitoring tools provide some insight into the fracture treatment results.

![Mobility Comparison

10

MOBILITY (mD/cP)

1

kh(Pr es Pwf )

q

u[ln( re / rw) S ]

0.1

0.01

0.001

0.0001

0.00001

0.000001

0.00001

0.0001

0.001

0.01

0.1

PERMEABILITY (mD)

Gas Shale

Bkkn Tight Oil

Tight Gas

1](https://image.slidesharecdn.com/shalegaspresentation-131123174649-phpapp01/85/Shale-gas-presentation-6-320.jpg)