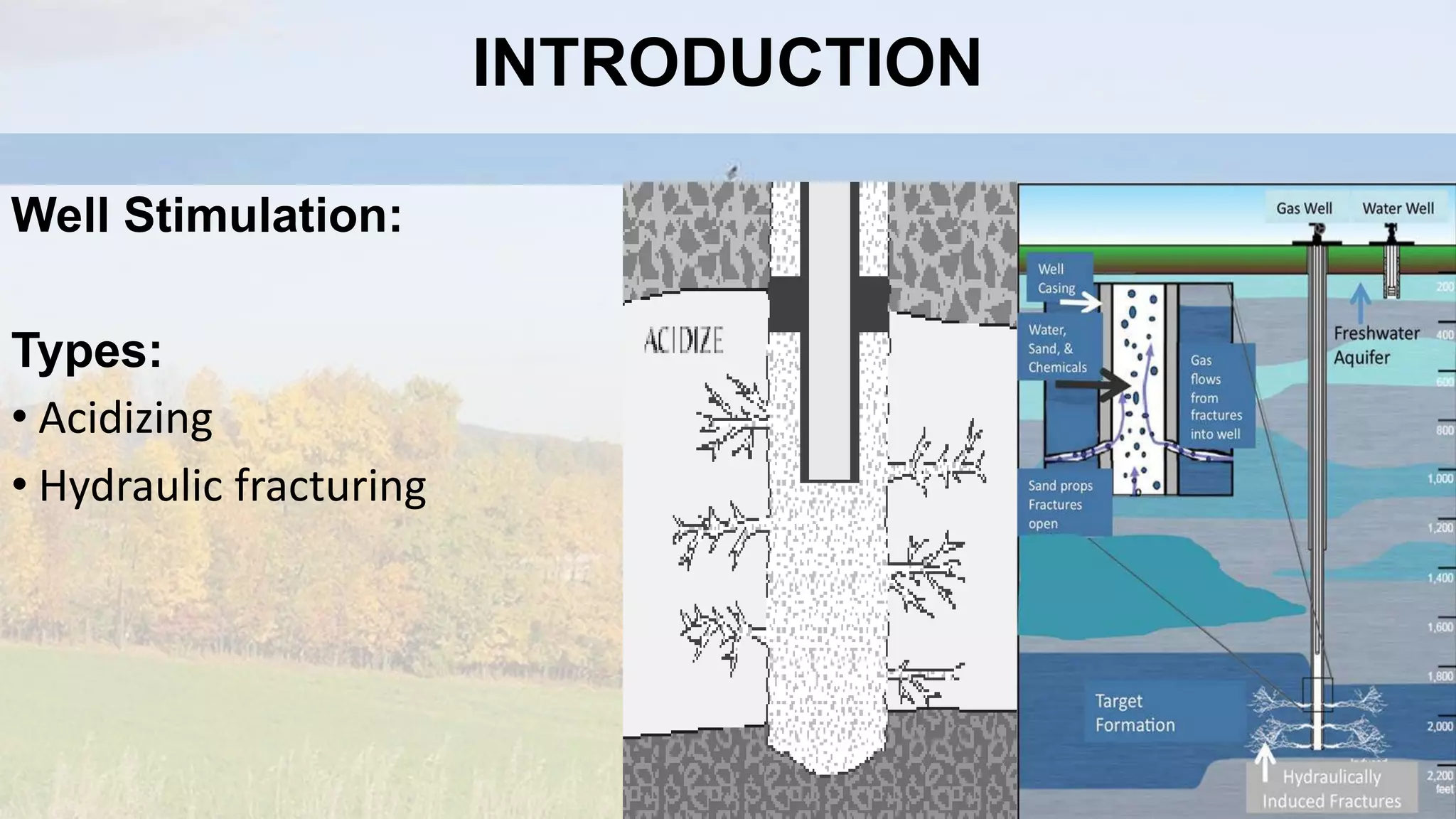

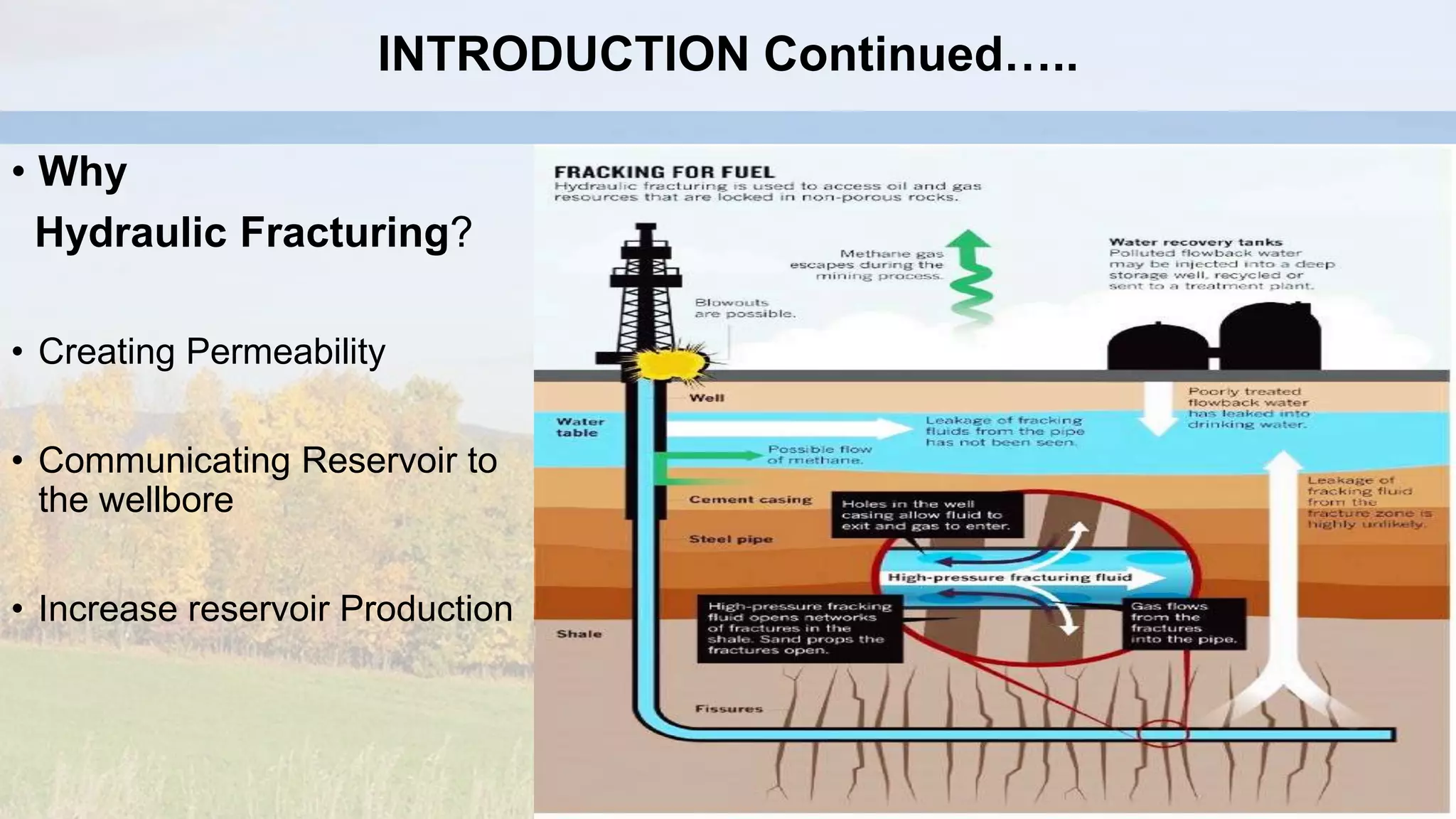

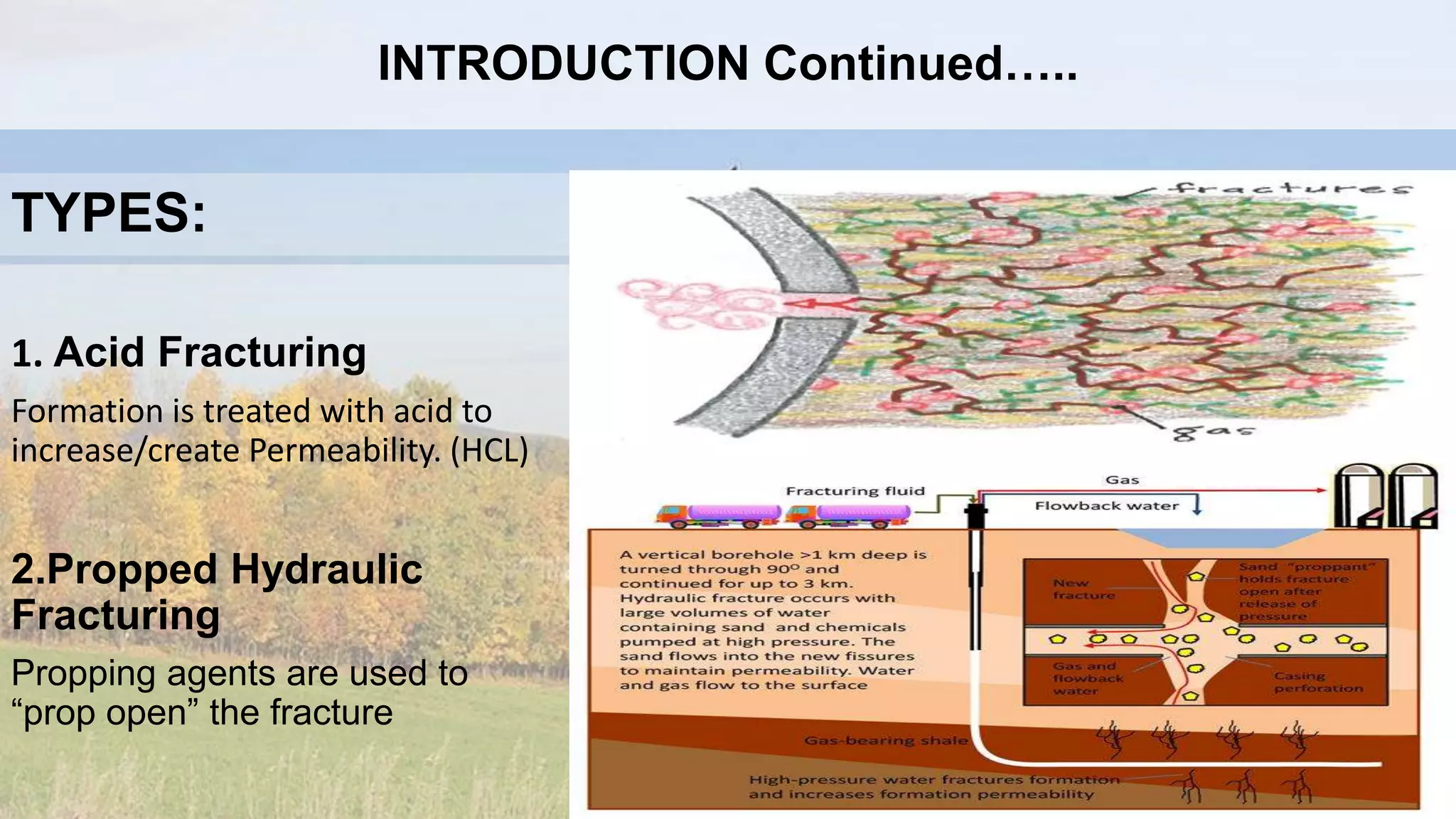

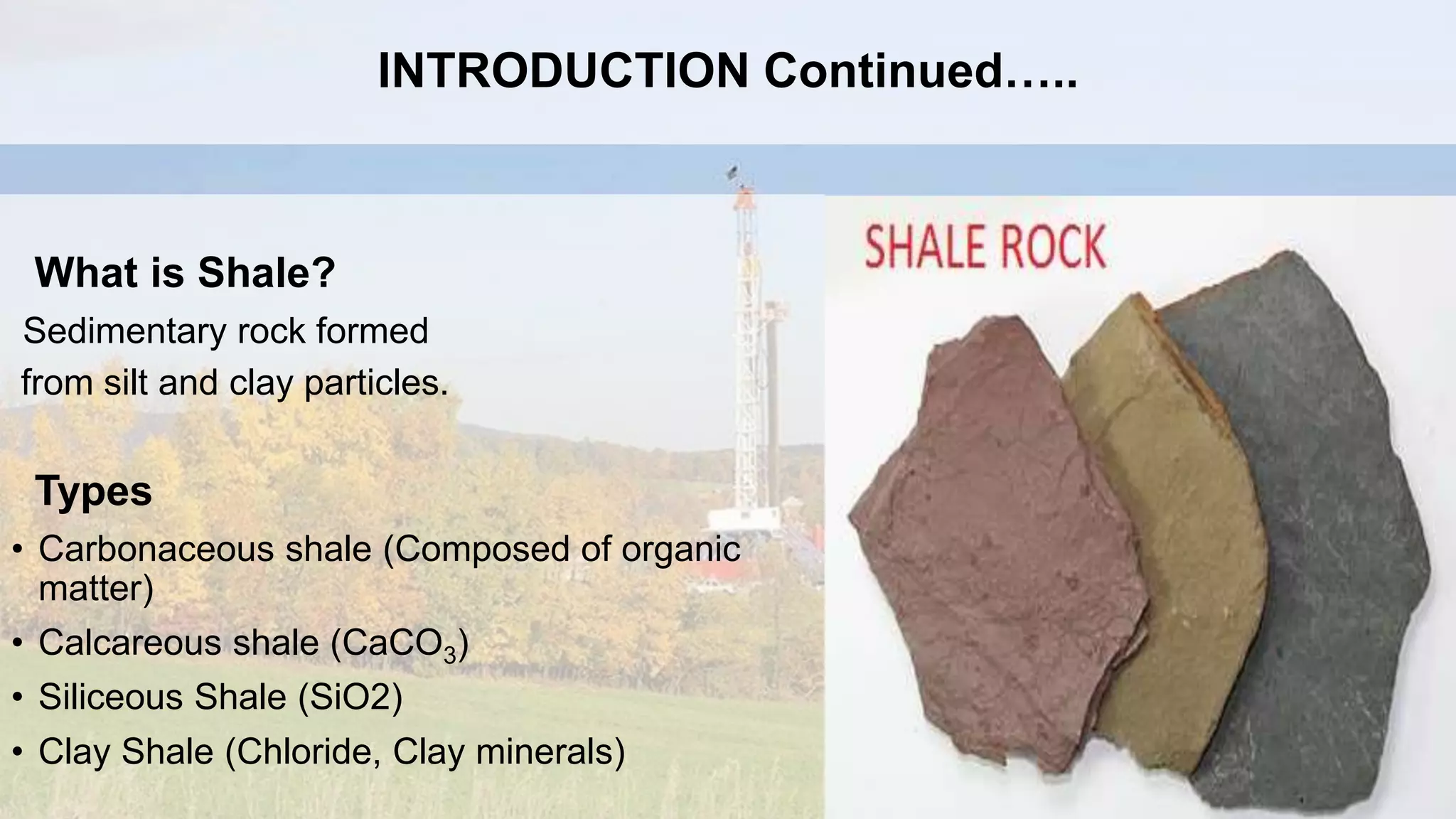

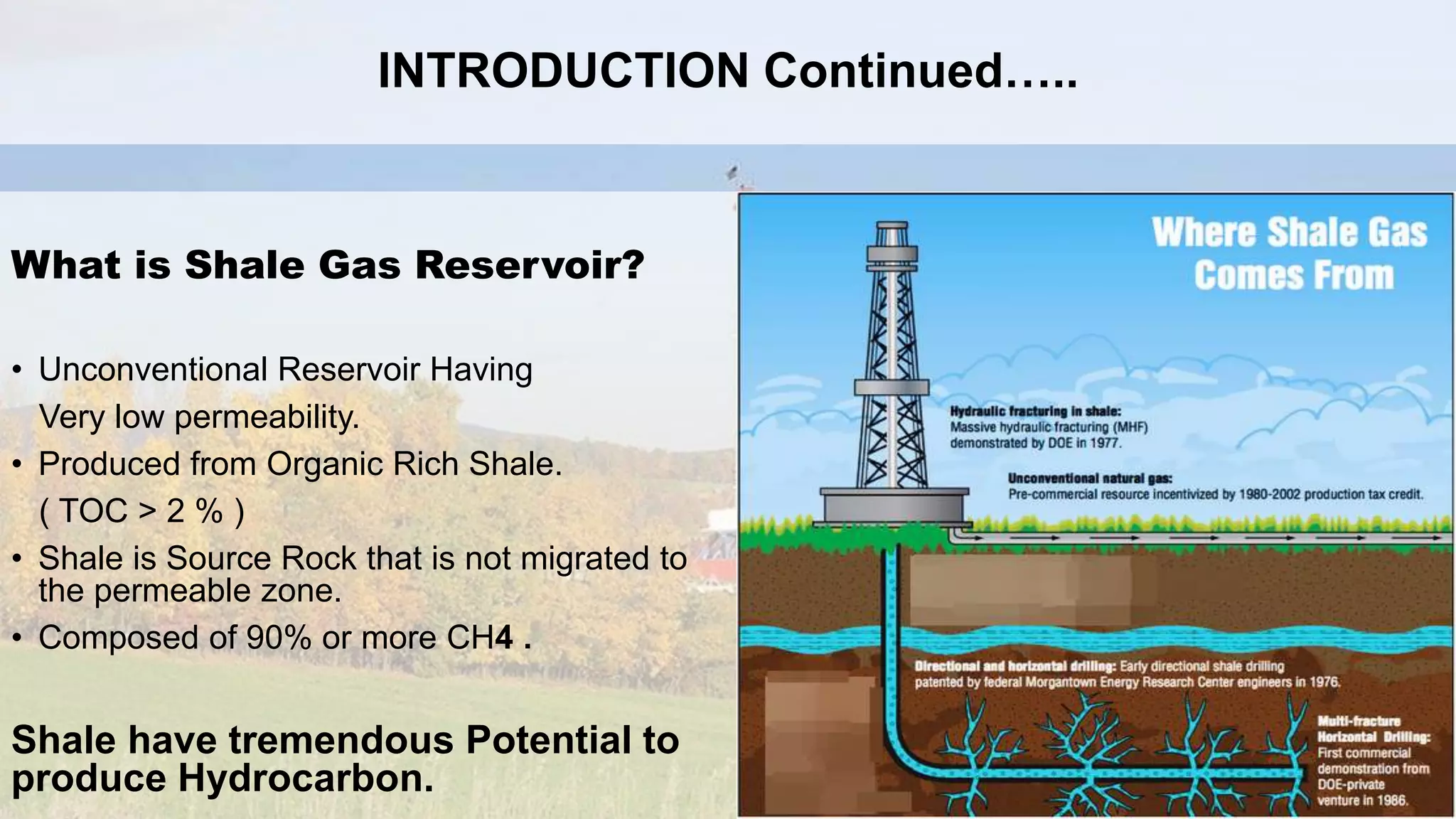

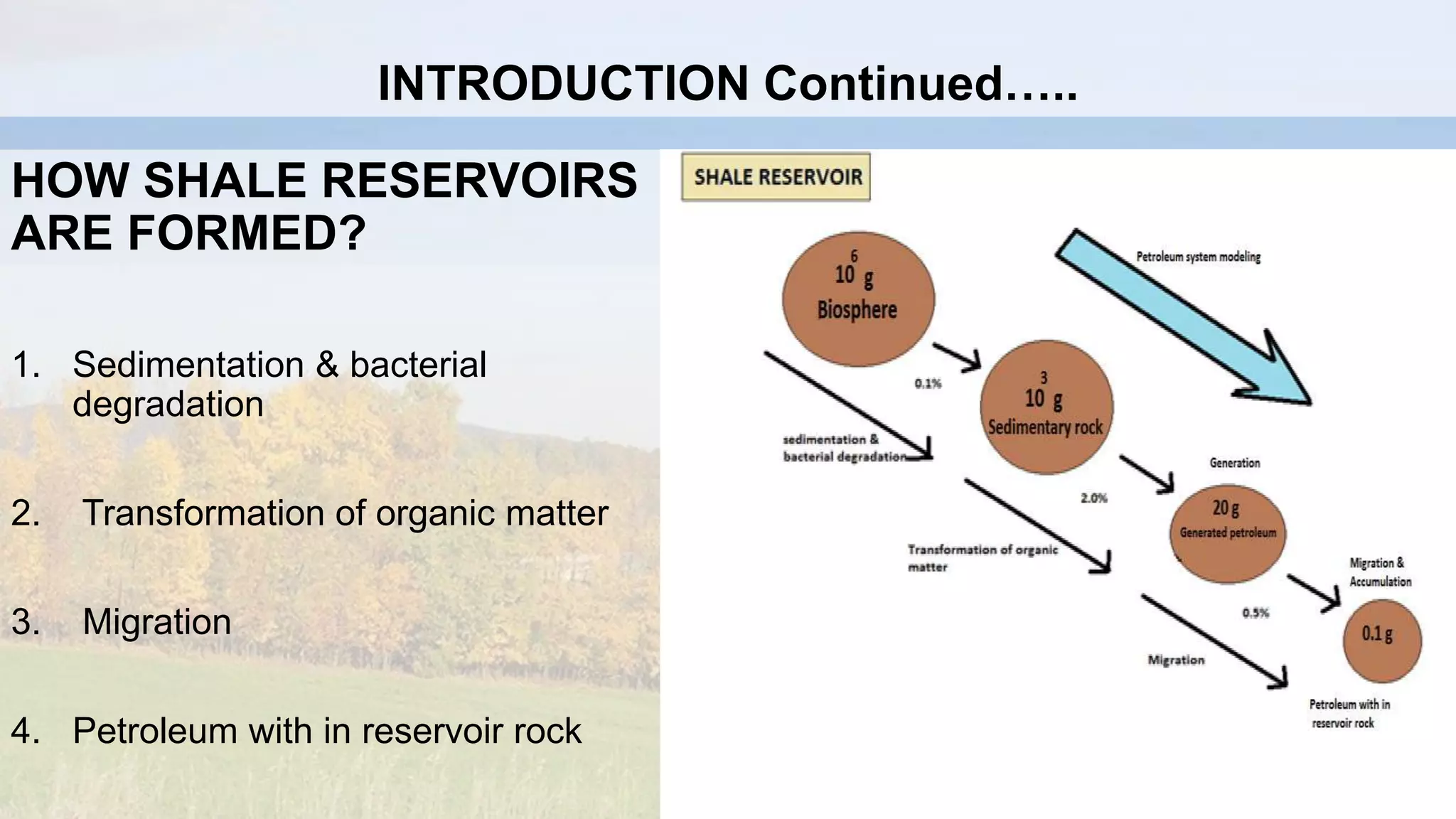

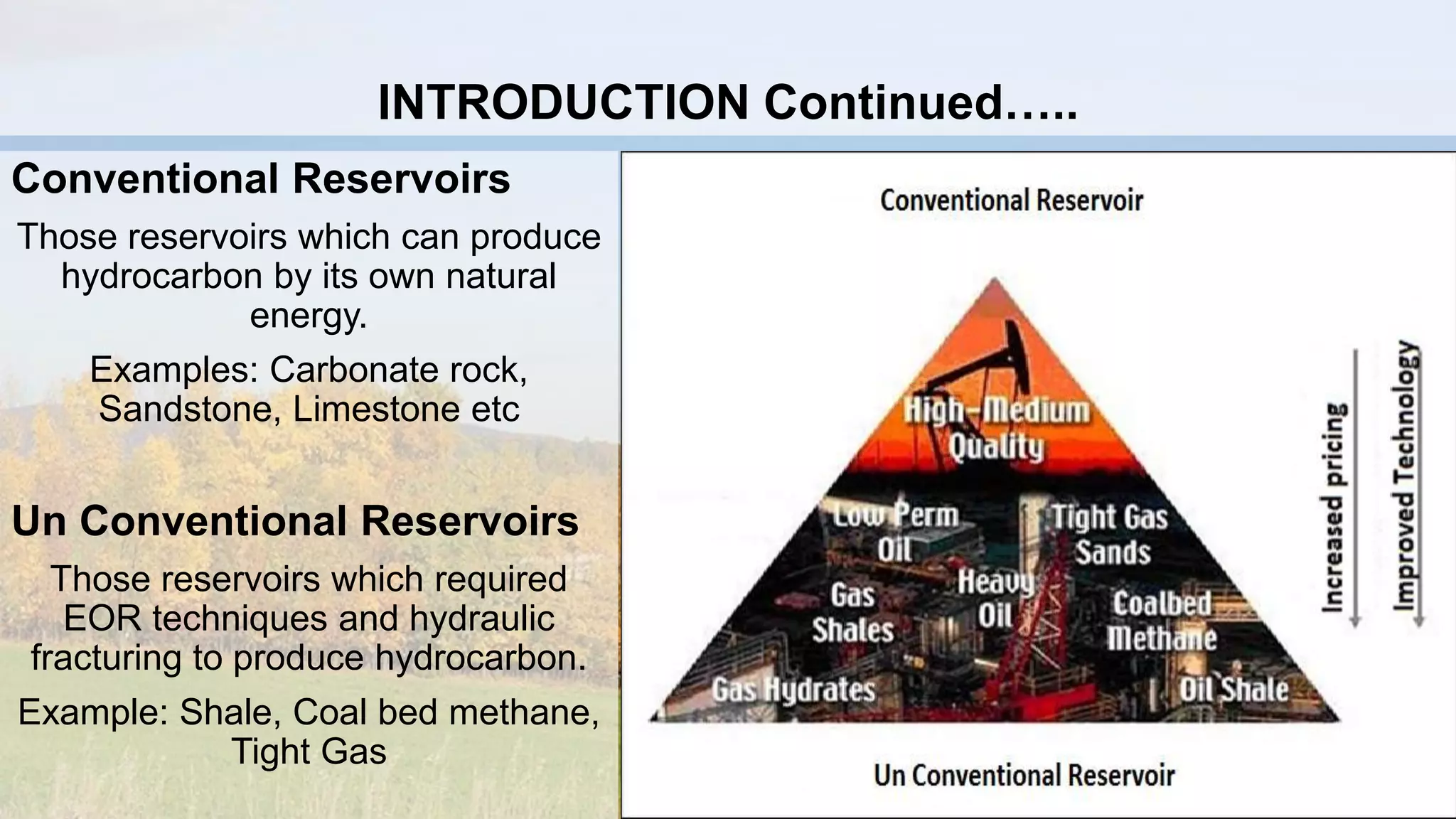

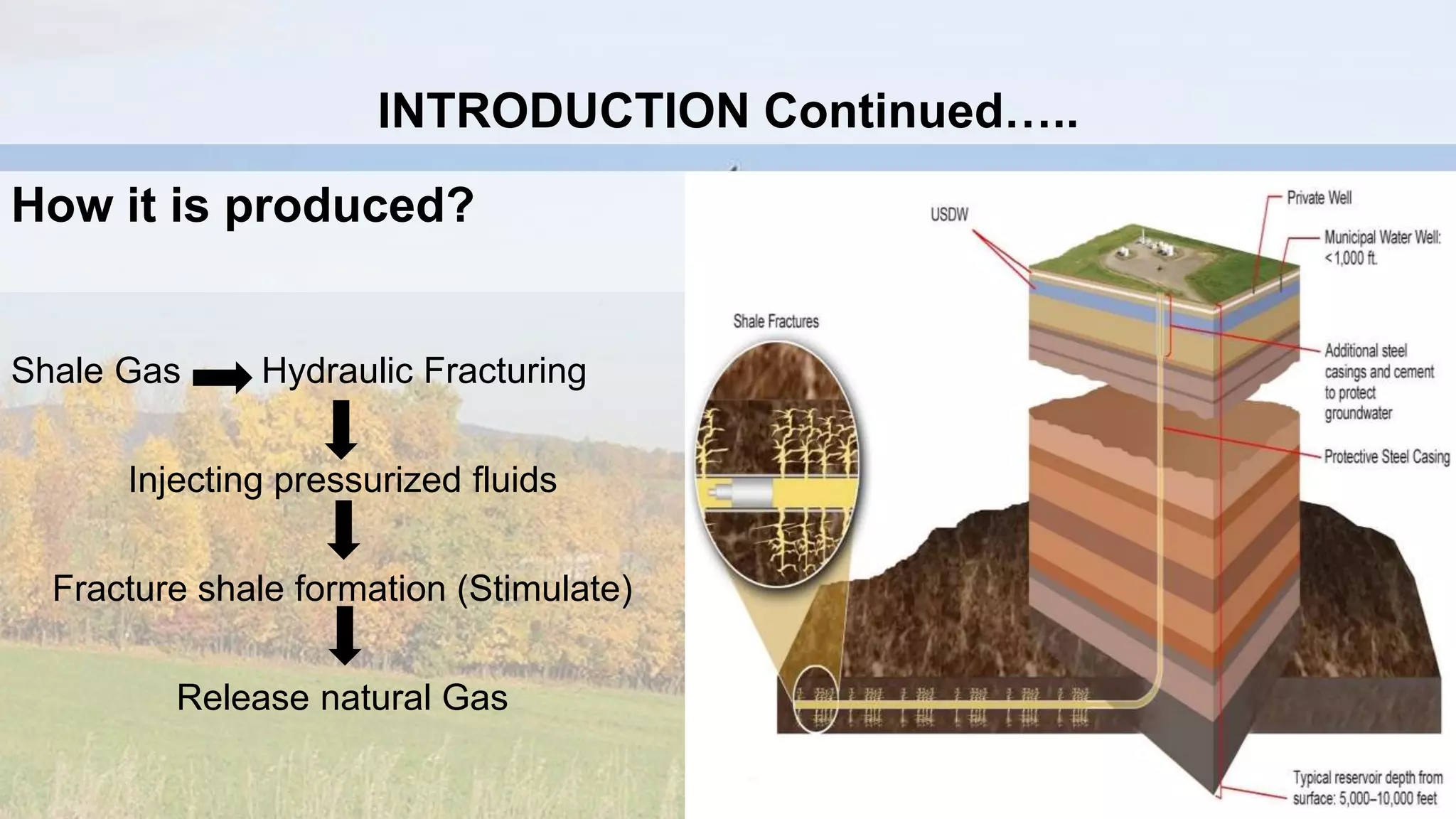

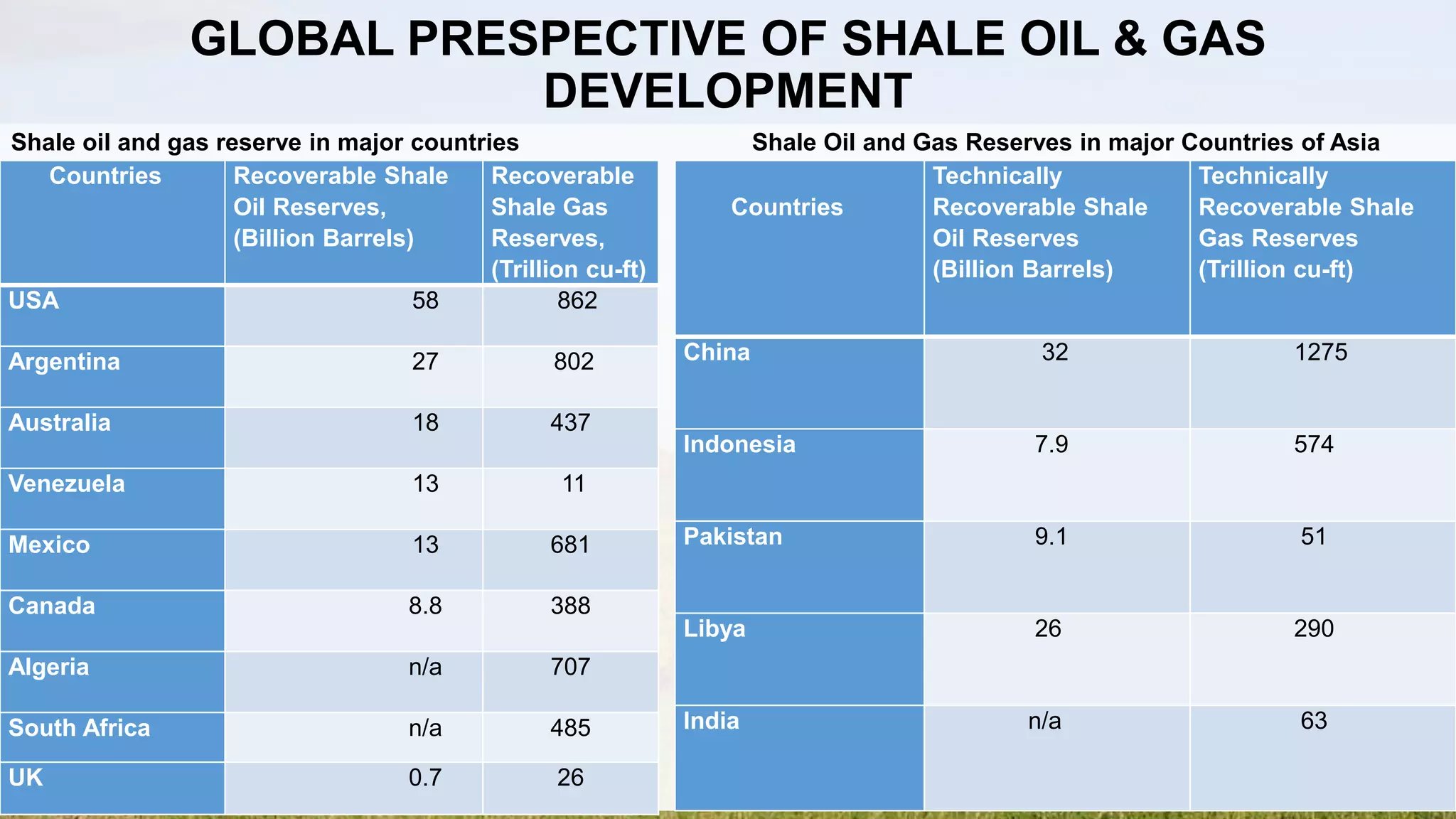

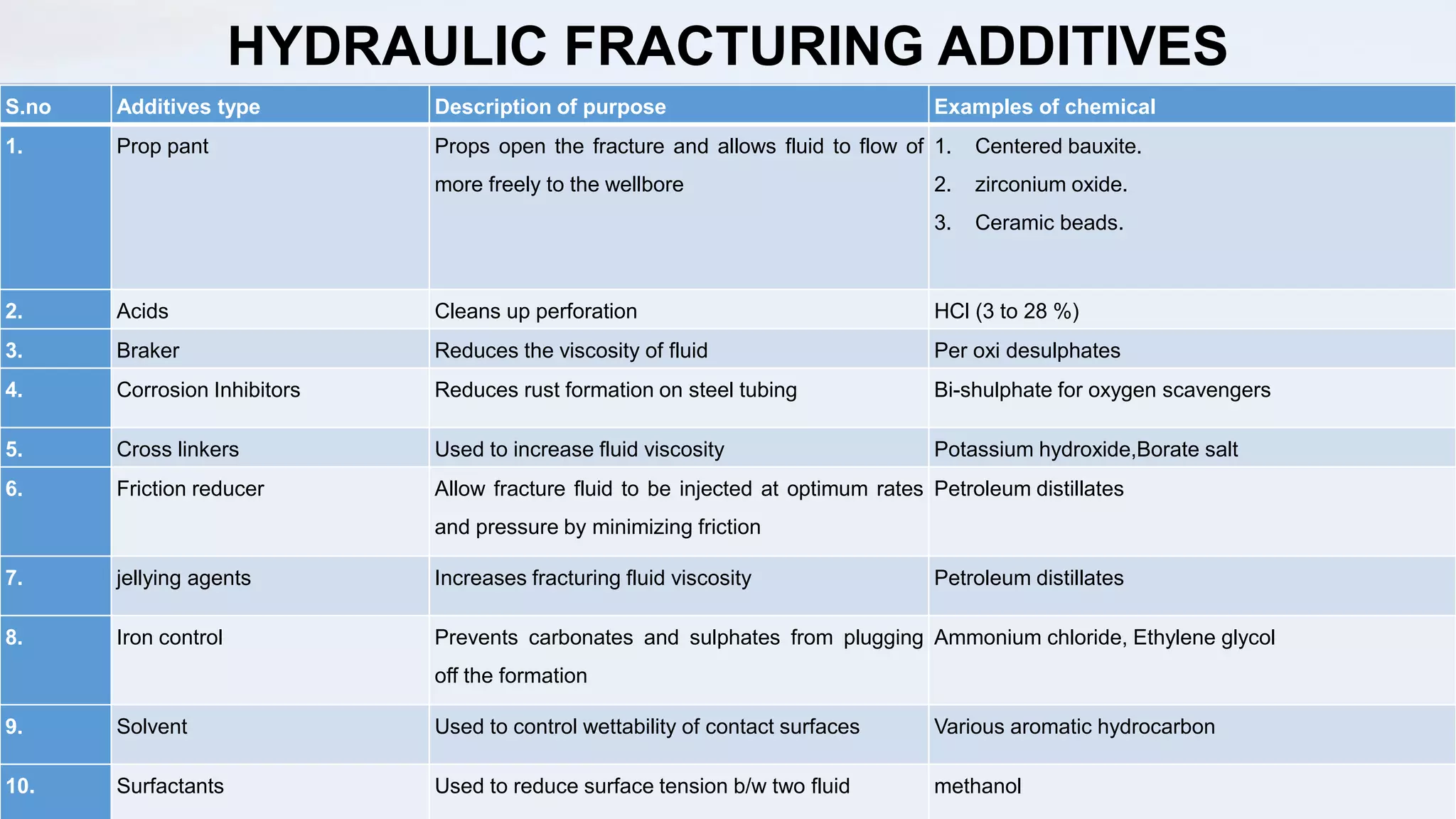

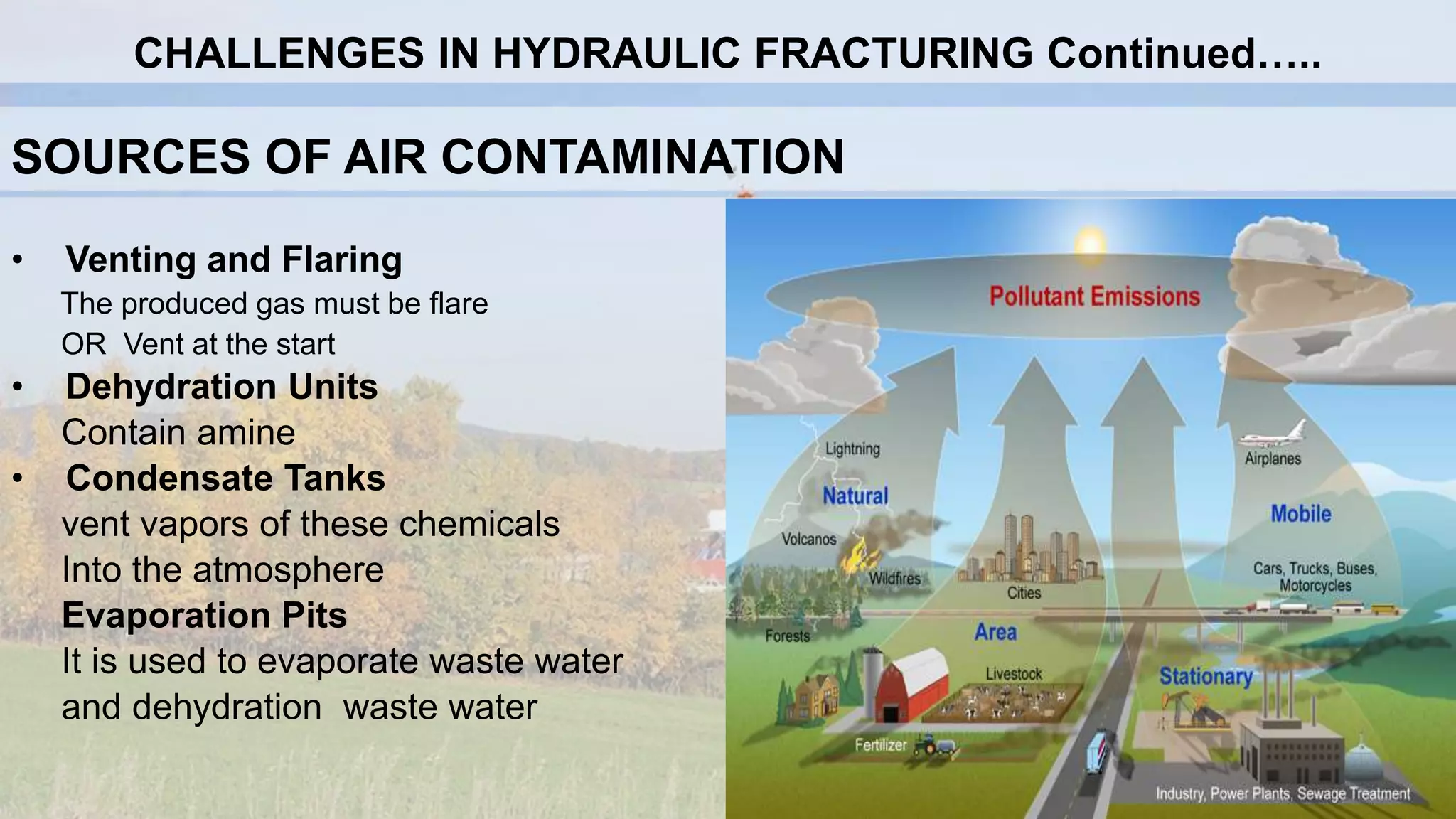

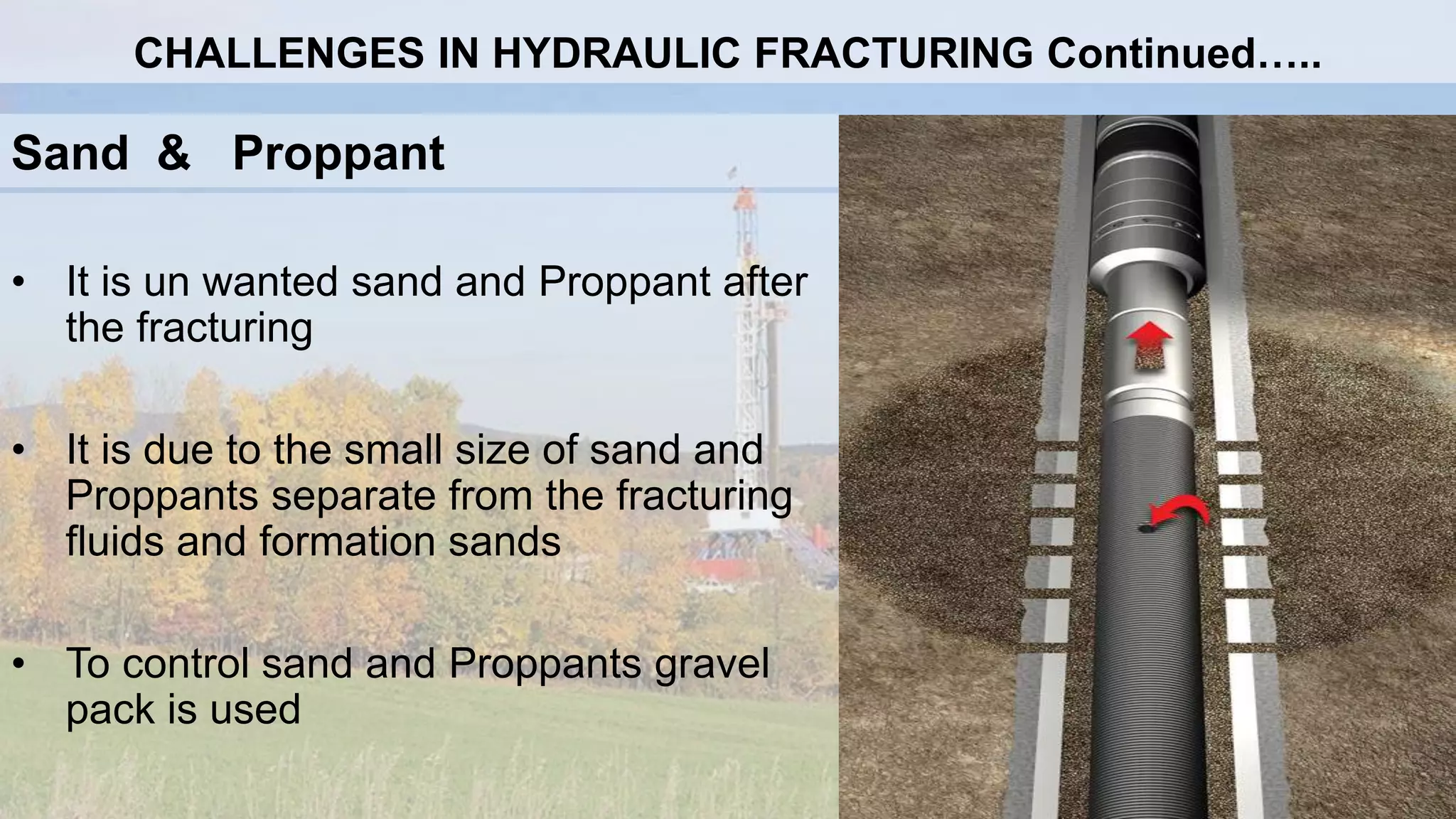

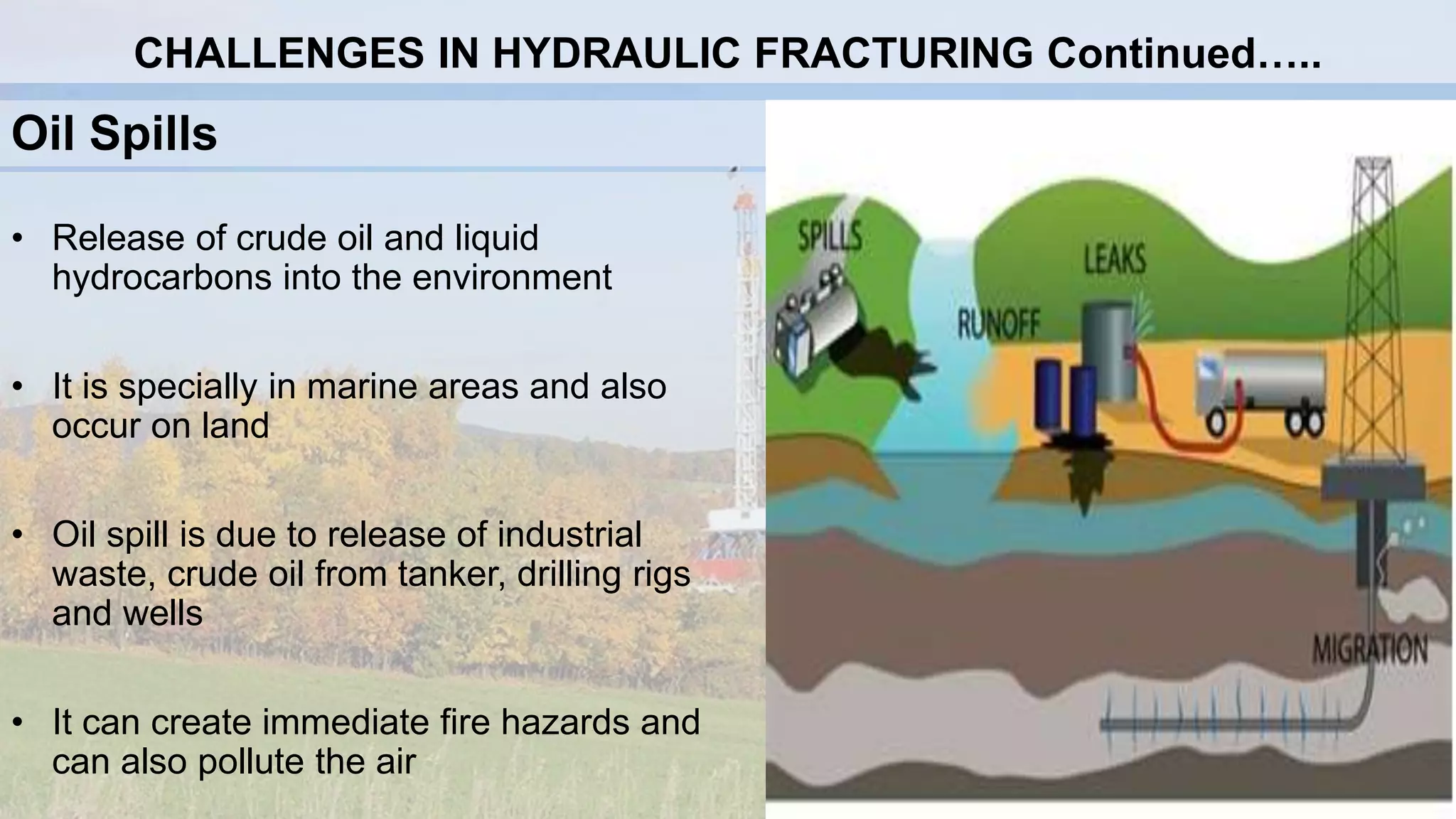

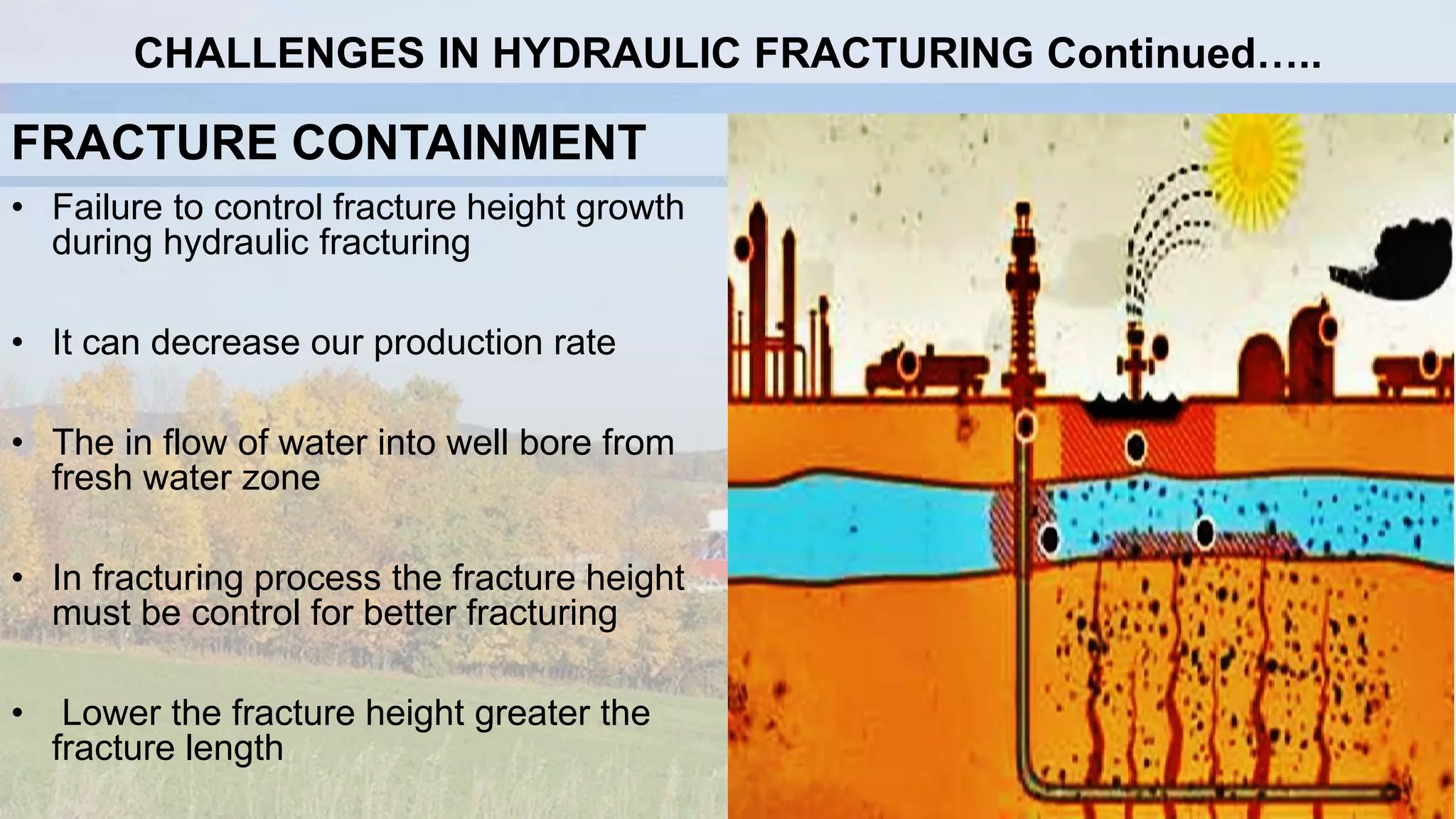

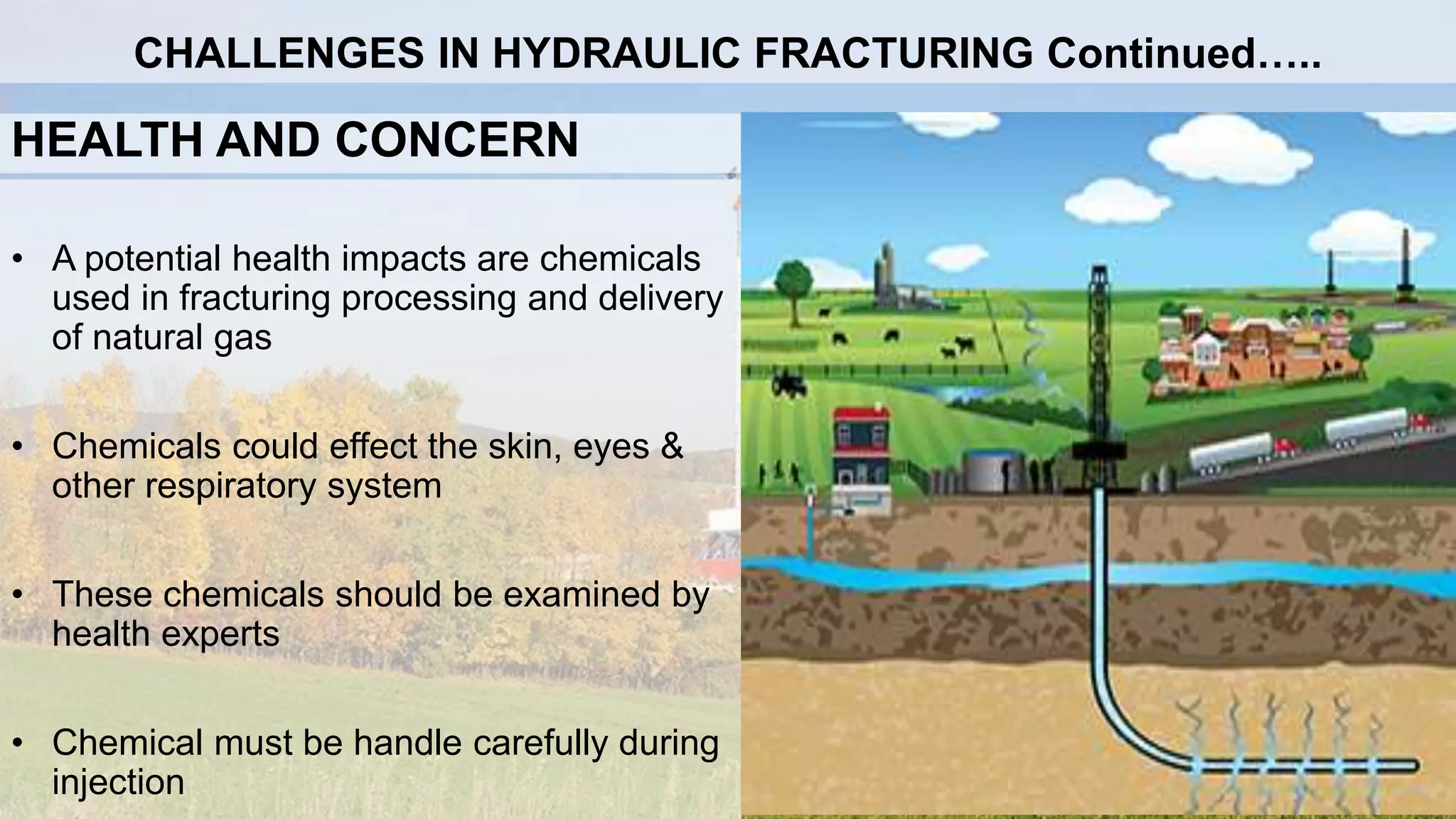

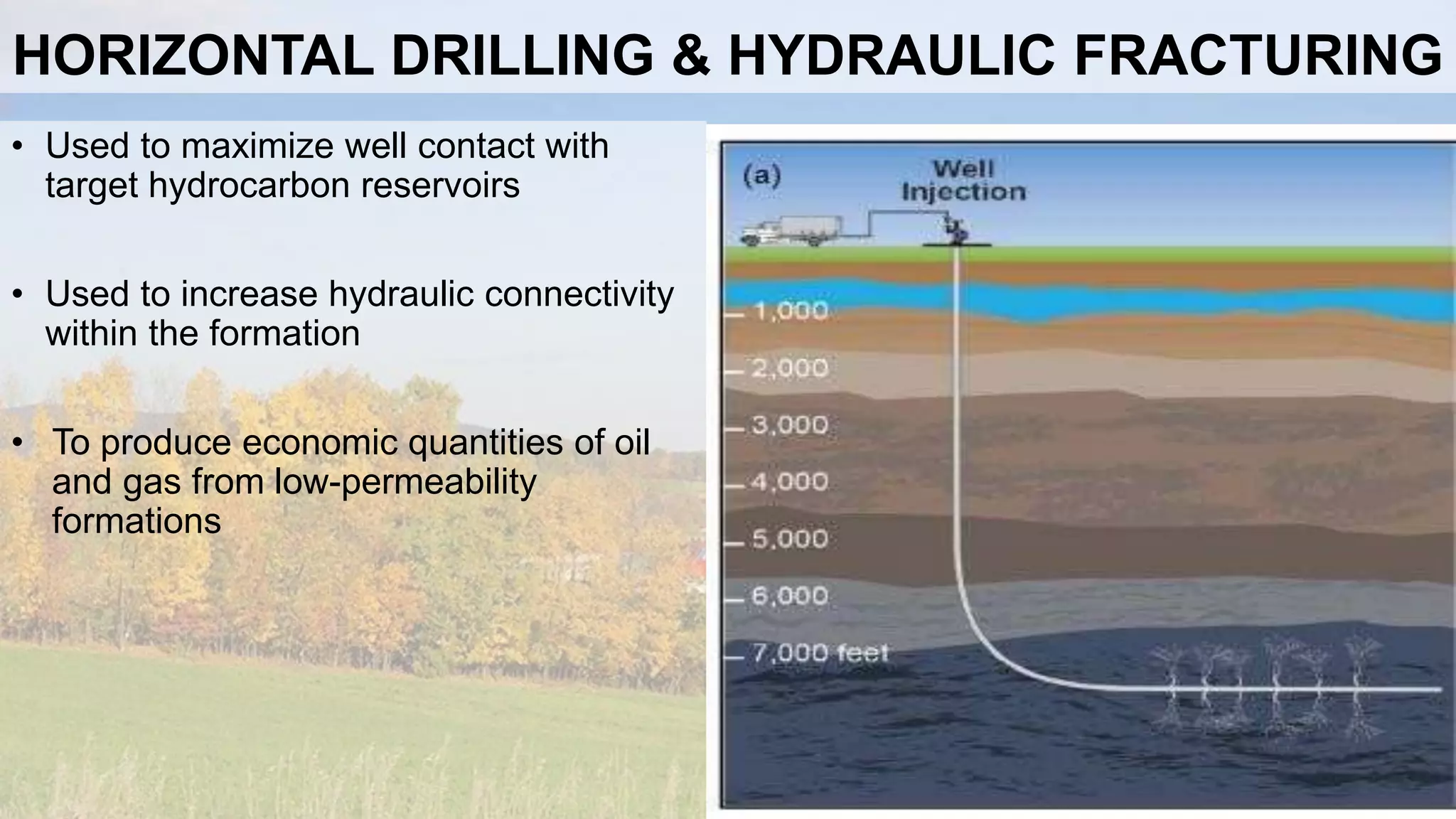

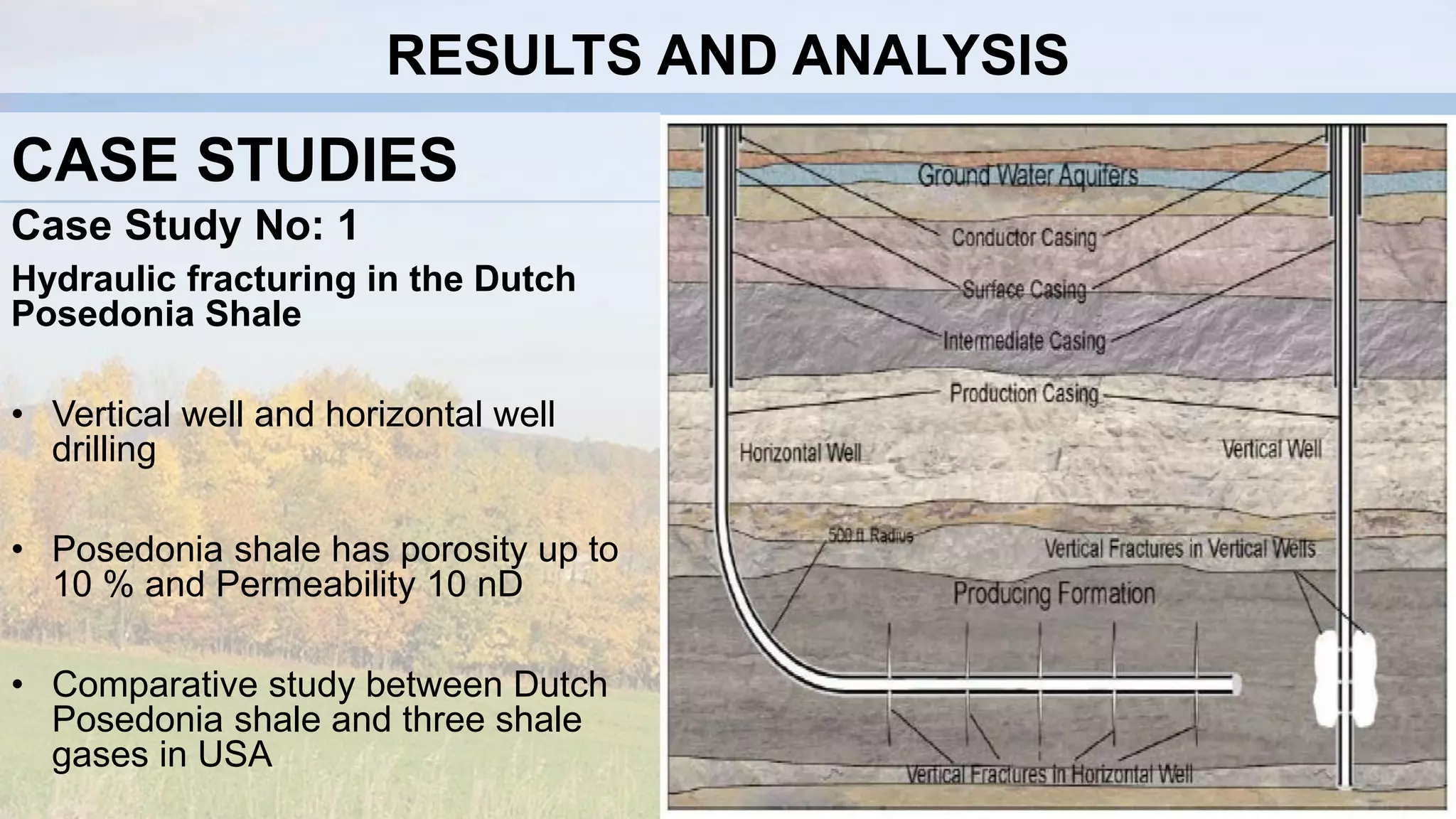

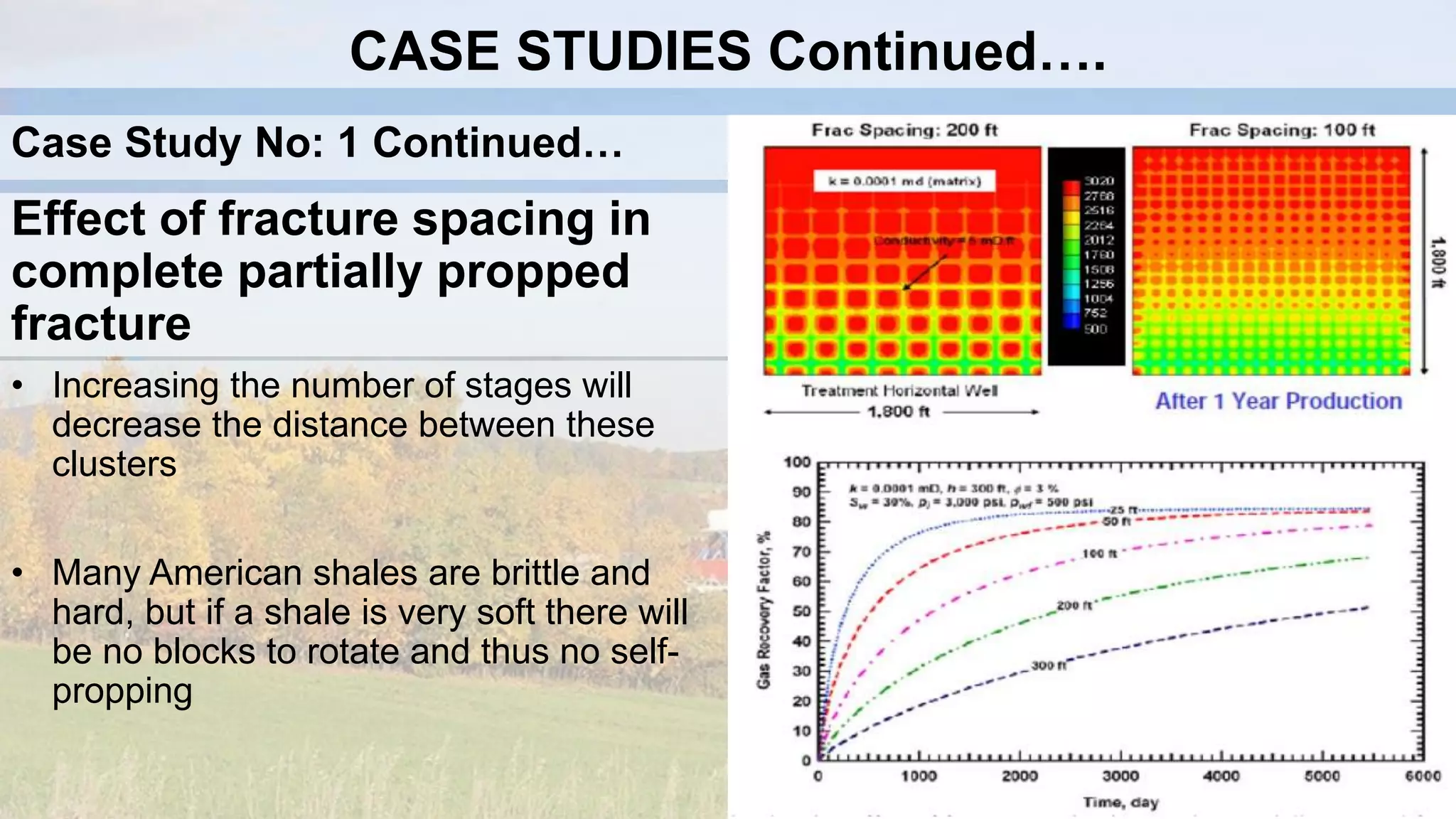

The document summarizes a final seminar presentation on optimization of shale gas production through hydraulic fracturing. It provides an outline of the presentation sections including introduction, objectives, literature review, methodology, and conclusions. The introduction defines well stimulation techniques like acidizing and hydraulic fracturing and their purposes. It describes the aims of increasing permeability and communication between wells and reservoirs. Key challenges of hydraulic fracturing discussed include potential water and air contamination from chemicals and activities, and management of materials like proppant and produced water.