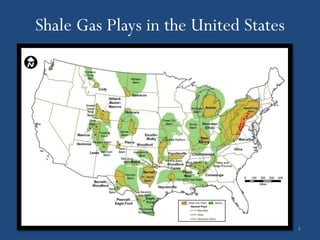

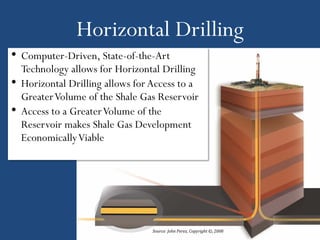

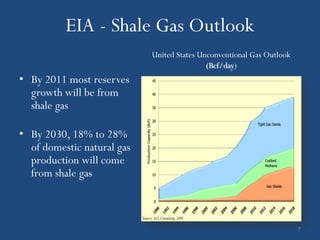

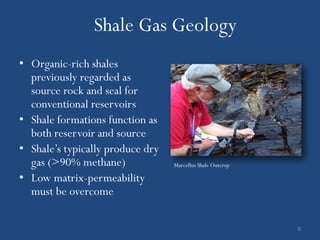

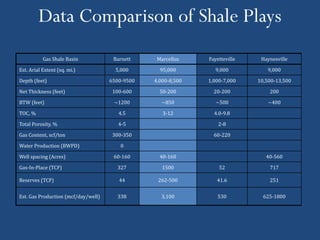

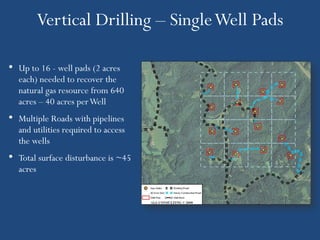

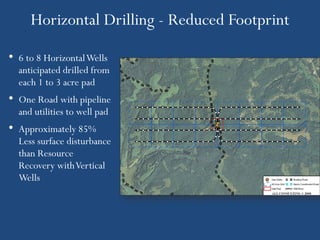

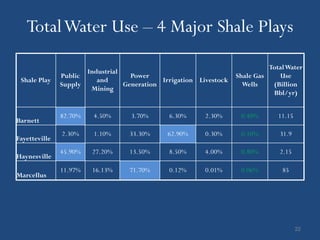

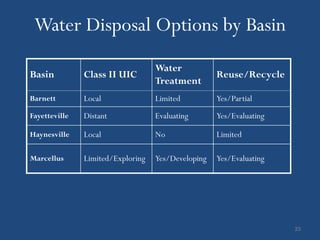

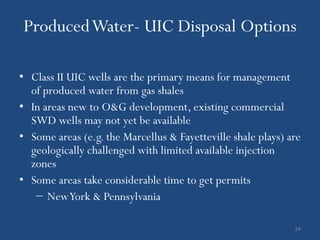

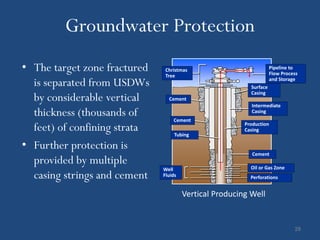

This document summarizes a presentation on modern shale gas development. It discusses how advances in horizontal drilling and hydraulic fracturing have made shale gas production economically viable in recent years. It provides an overview of major shale gas plays in the US and details of the geology, drilling, fracturing process and environmental considerations of shale gas development. The presentation emphasizes how horizontal drilling reduces surface impacts compared to vertical wells and discusses water sourcing, reuse and disposal in different shale basins.