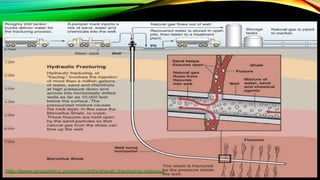

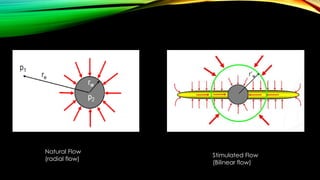

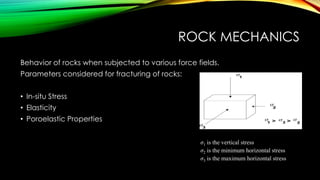

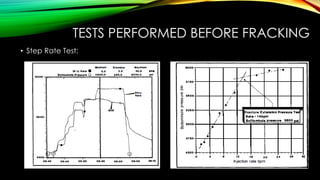

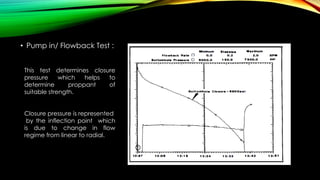

Hydraulic fracturing involves pumping water mixed with proppant and additives into wells at high pressure to create fractures in rock formations and stimulate oil and gas production. The first successful hydraulic fracturing jobs occurred in the 1940s and 1950s. The process involves pad, slurry, and flowback stages. Parameters like in-situ stress, elastic properties, and fluid properties are considered for fracturing design. Fluid additives are used to carry proppant into the fracture and improve fluid properties. Pre-fracturing tests like step-rate and pump-in/flowback tests help determine fracture and closure pressures. Hydraulic fracturing has enabled production from tight shale and coalbed methane reservoirs.