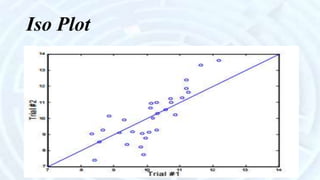

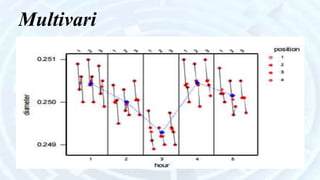

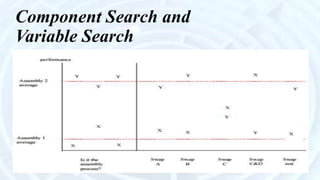

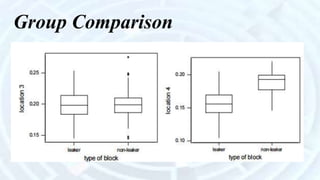

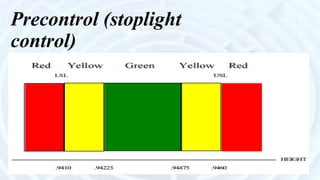

Dorian Shainin was an American quality consultant and engineer notable for developing the "Red X" concept for industrial problem solving and product reliability. Shainin tools provide a simplified approach to Design of Experiments to logically identify root causes of variation. The key Shainin tools are Iso Plot, Multivari, Component Search and Variable Search, Group Comparison, and Precontrol (stoplight control). Shainin referred to root causes as "Red X" primary causes, "Pink X" secondary causes, and "Pink-Pink X" minor but still controllable causes.