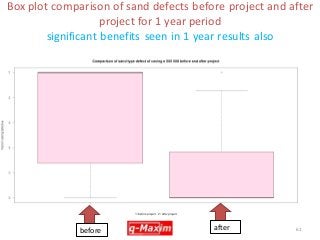

The document discusses Q-Maxim's approach to reducing defects in sand casting through a combination of Taguchi methods and machine learning. A case study highlights the project's aim to decrease top defects and repair costs by optimizing various manufacturing factors, leading to significant improvements in defect rates and welding material consumption. The results of the experimental design and confirmatory runs demonstrate a 59% reduction in defect levels and a 70% decrease in welding electrodes used for repairs.

![Business case – background, goal of project

•Defect levels in the industry are somewhat similar

•Traditional problem solving approaches unsuccessful

•Target :

1.Reduce top 3 defects by 50%

2.Reduce cost of repair by welding by 50%

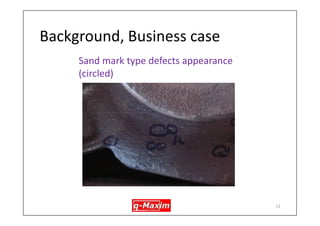

[See picture of sand mark type defect in the next slide]

15](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-14-320.jpg)

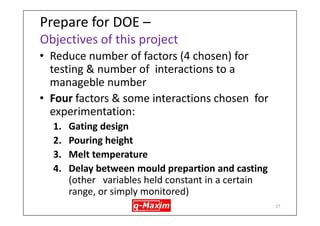

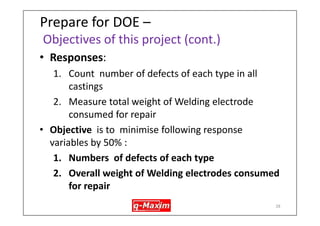

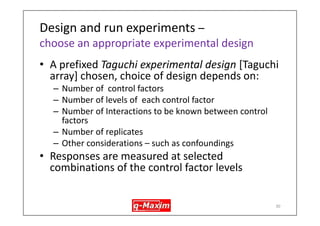

![Design and run experiments – choose an appropriate experimental design

•A prefixed Taguchi experimental design [Taguchi array] chosen, choice of design depends on:

–Number of control factors

–Number of levels of each control factor

–Number of Interactions to be known between control factors

–Number of replicates

–Other considerations – such as confoundings

•Responses are measured at selected combinations of the control factor levels

39](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-38-320.jpg)

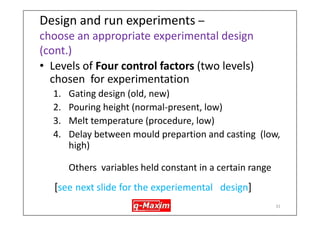

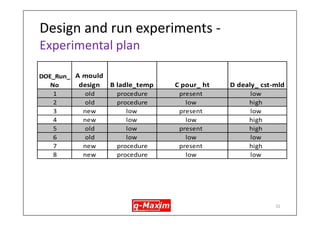

![Design and run experiments – choose an appropriate experimental design (cont.)

•Levels of Four control factors (two levels) chosen for experimentation

1.Gating design (old, new)

2.Pouring height (normal-present, low)

3.Melt temperature (procedure, low)

4.Delay between mould prepartion and casting (low, high) Others variables held constant in a certain range

[see next slide for the experiemental design]

40](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-39-320.jpg)

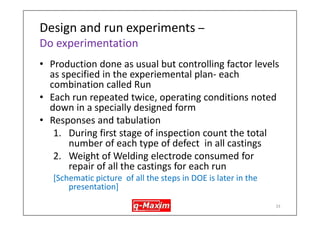

![Design and run experiments – Do experimentation

•Responses and tabulation

1.During first stage of inspection count the total number of each type of defect in all castings

2.Weight of Welding electrode consumed for repair of all the castings for each run

[Schematic picture of all the steps in DOE is later in the presentation]

43](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-42-320.jpg)

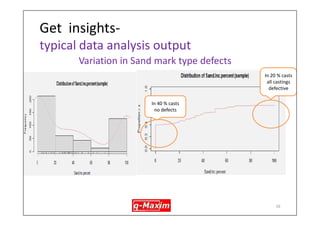

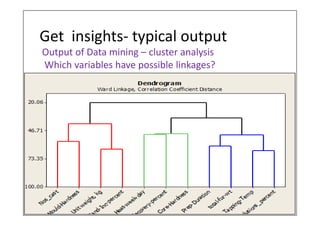

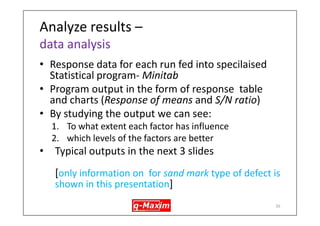

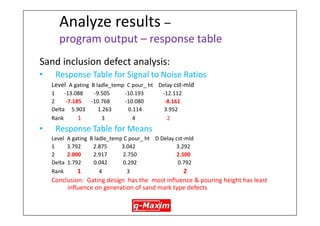

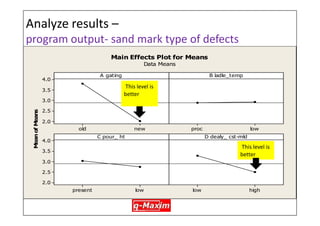

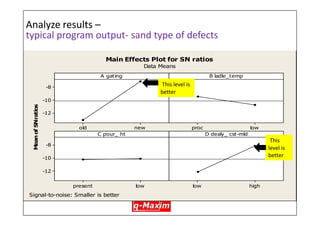

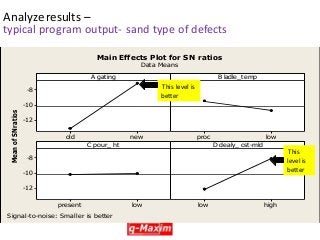

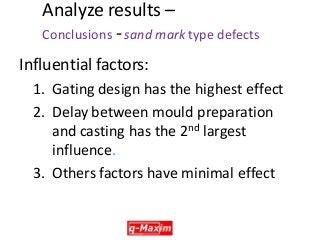

![Analyze results – data analysis

•By studying the output we can see:

1.To what extent each factor has influence

2.which levels of the factors are better

•Typical outputs in the next 3 slides [only information on for sand mark type of defect is shown in this presentation]

46](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-45-320.jpg)

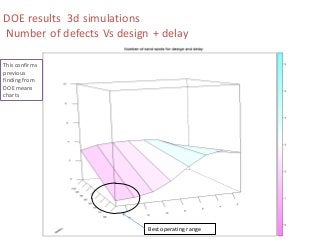

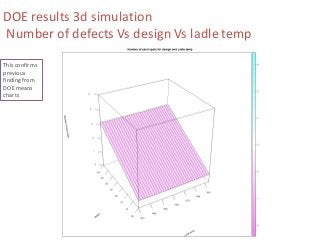

![Analyze results – Findings were confirmed by using machine learning

•A statistical model was built using machine learning algorithm of Artificial neural networks

•Simulation was done, data generated, and 3d plot was made with response (i.e. number of sand type defects ) in z axis & important features in x & y axis

[see next 2 slides]](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-51-320.jpg)

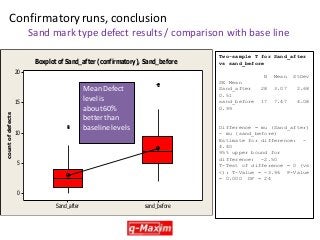

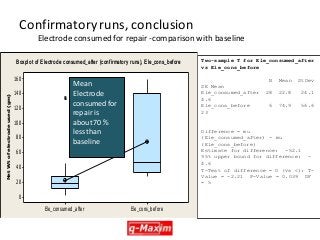

![Confirmatory runs, conclusions- Confirmatory runs

•It is necessary to confirm findings by repeating the runs under most desirable levels of influential factors & compare the responses with baseline levels

•Responses are compared by

1. Box plot and

2. statistical tests

[Comparison shown in next two slides]](https://image.slidesharecdn.com/q-maximsapproachtowastereductionfoundryexamplev1-1-120707064658-phpapp02/85/q-Maxim-s-approach-to-waste-reduction-in-foundry-application-using-Taguchi-method-and-Machine-learning-55-320.jpg)