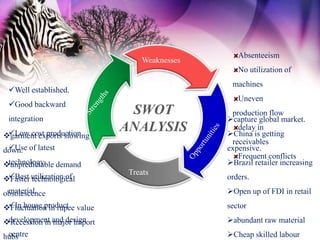

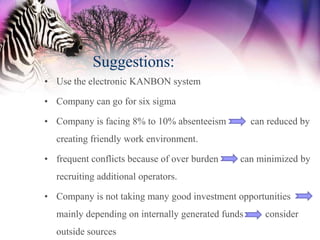

Shahi Exports Pvt. Ltd is a leading apparel manufacturer in India established in 1974. It has expanded significantly over 30 years from 250 associates to producing 3 million pieces per month. The presentation analyzed Shahi's organizational structure, production process, strengths as a well-established low-cost producer, and opportunities to improve efficiency and utilize investment opportunities. Suggestions included implementing an electronic Kanban system and reducing absenteeism to improve productivity.