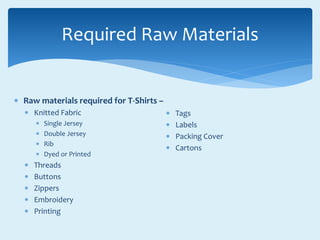

This document proposes a factory layout plan for a T-shirt manufacturing unit located at Brandix India Apparel City in Visakhapatnam, Andhra Pradesh. It includes details on the proposed products (round neck, crew neck, and V-neck T-shirts), required raw materials, available infrastructure and resources at the site, proposed machinery and equipment, estimated production needs, manpower requirements, and material flow through the production process. Floor area requirements are allocated for each department including raw material storage, cutting, sewing, finishing, packing, and other support areas.