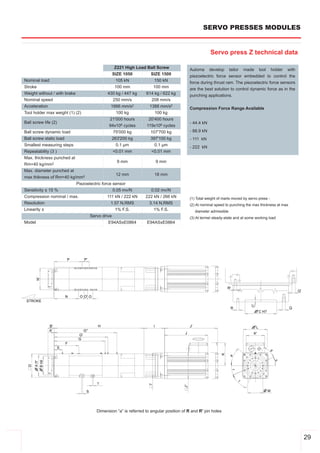

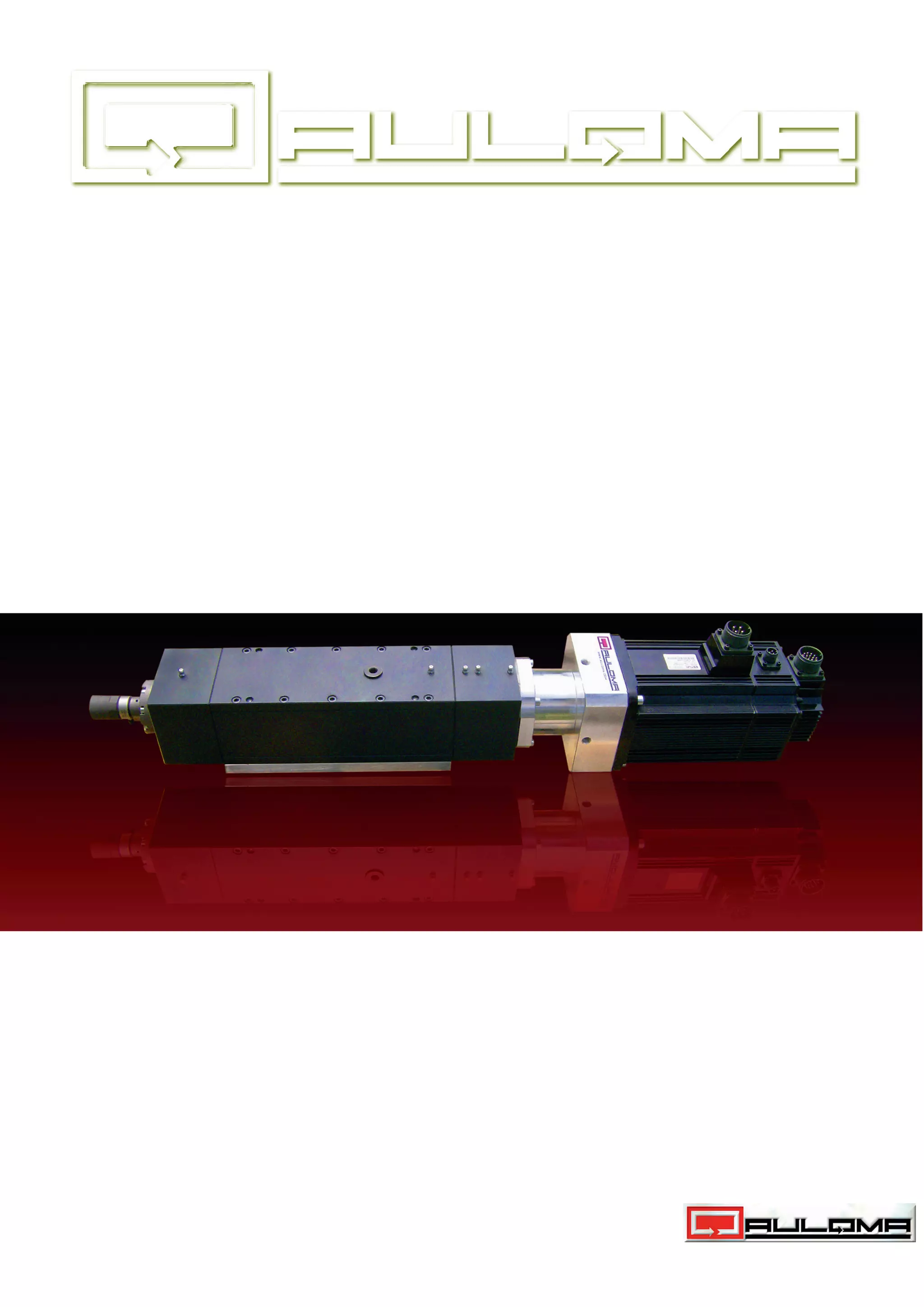

The document provides an overview of Auloma's OEM modular devices for press monitoring, detailing various models of servo and electromechanical presses, their specifications, and functionalities. It emphasizes the importance of selecting the appropriate force sensor, highlighting the differences between piezoelectric and strain gauge sensors for specific applications. Additionally, the document discusses the integration of motion control and process monitoring systems to optimize production quality and efficiency in manufacturing environments.

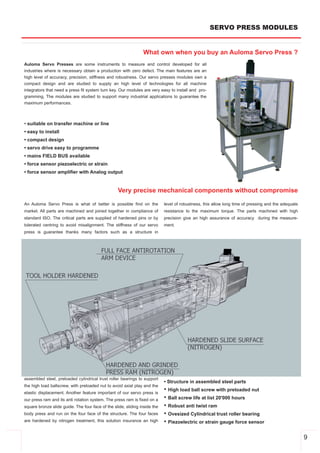

![SERVO PRESSES MODULES

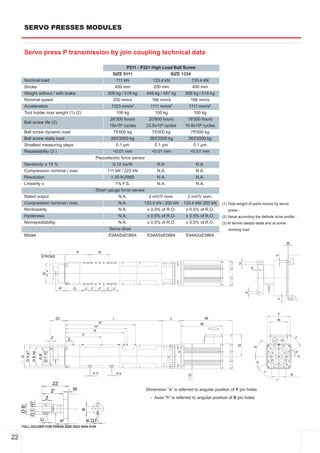

Servo drive features

servo drive E94ASxE

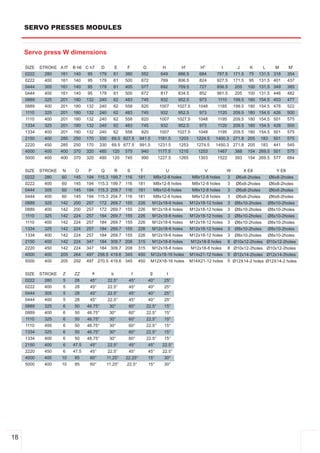

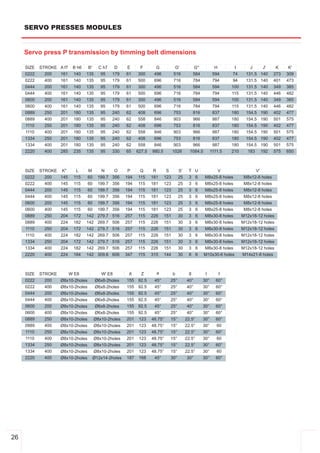

Size 0134 0174 0324 0594 0864 1044 1454 1724 2024

Mains voltage range 3/PE AC 180 V 0 % … 550 V +0 %; 45 Hz 0 % … 65 Hz +0 %

Rated output current [A] 16.5 23.5 32 59 86 104 145 172 202

Rated switching frequency [kHz] 8 8 8 4 4 4 4 4 4

Max. output current 1) [A] 49.5 58.8 76,8 118 172 208 261 310 364

Typical motor power [kW] 7.5 11 15 30 45 55 75 90 105

Electronics supply Internal; alternatively DC 24 V external

Brake chopper Integrated

Brake resistor External

Dimensions (H x W x D) [mm] 481 x 60 x 288 602 x 206 x 294 702 x 266 x 370 930x407x427 1199 x 407 x 427

A B

C

size a b b1 b2 e c1 d g m kg

0134 120 8

A

0174 120 8

0324 206 606 556 630 294 170 585 6.5 12.5 26.5

0594 206 606 556 630 294 170 585 6.5 12.5 26.5

B

0864 266 706 655 729 370 230 685 6.5 12.5 42

1044 266 706 655 729 370 230 685 6.5 12.5 42

1454 930 897 885 95

1724 1199 1166 1154 107 C

2024 1199 1166 1154 109

mm

12](https://image.slidesharecdn.com/main-catalogue-121013023754-phpapp02/85/Servo-press-auloma-catalogue-14-320.jpg)