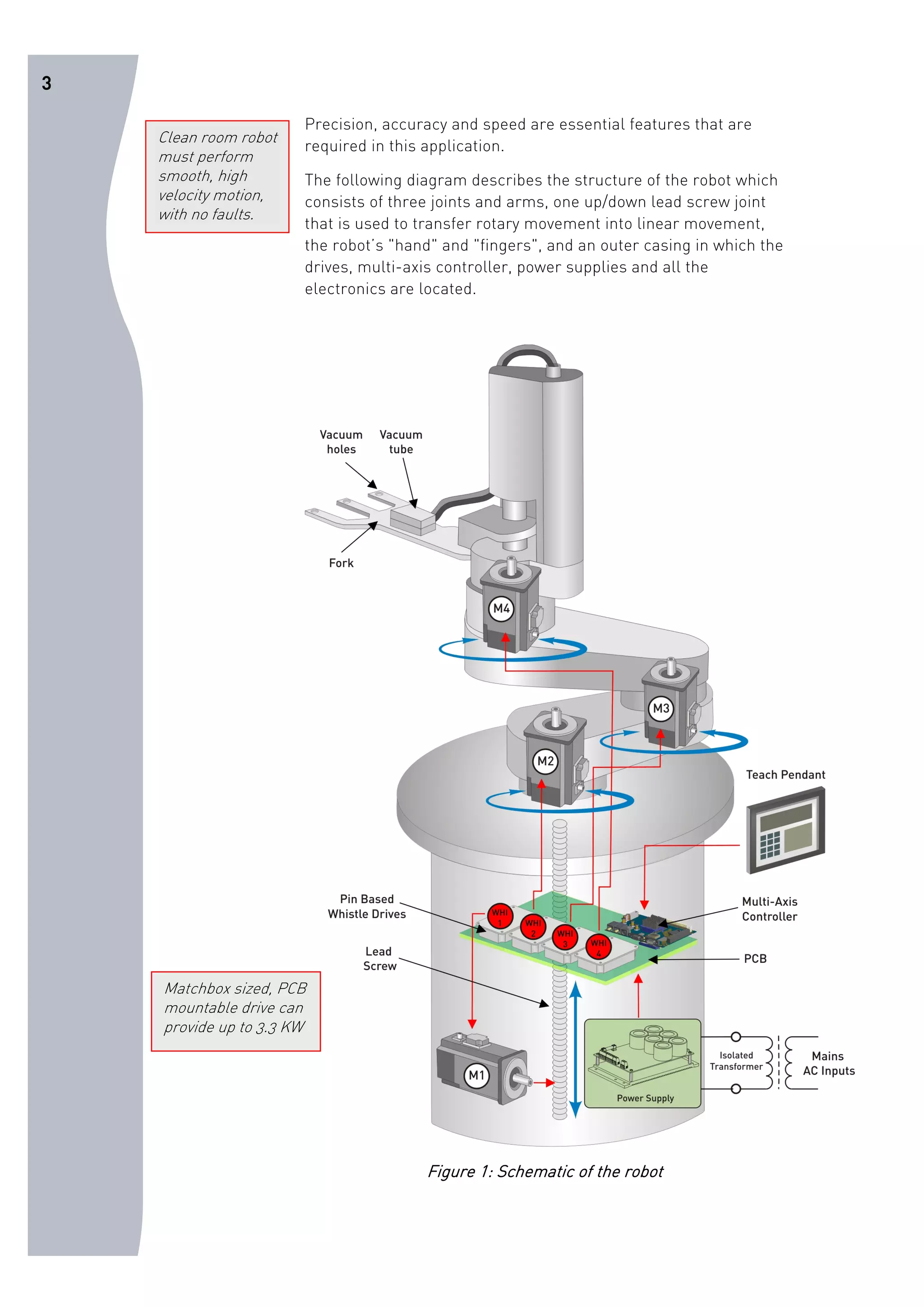

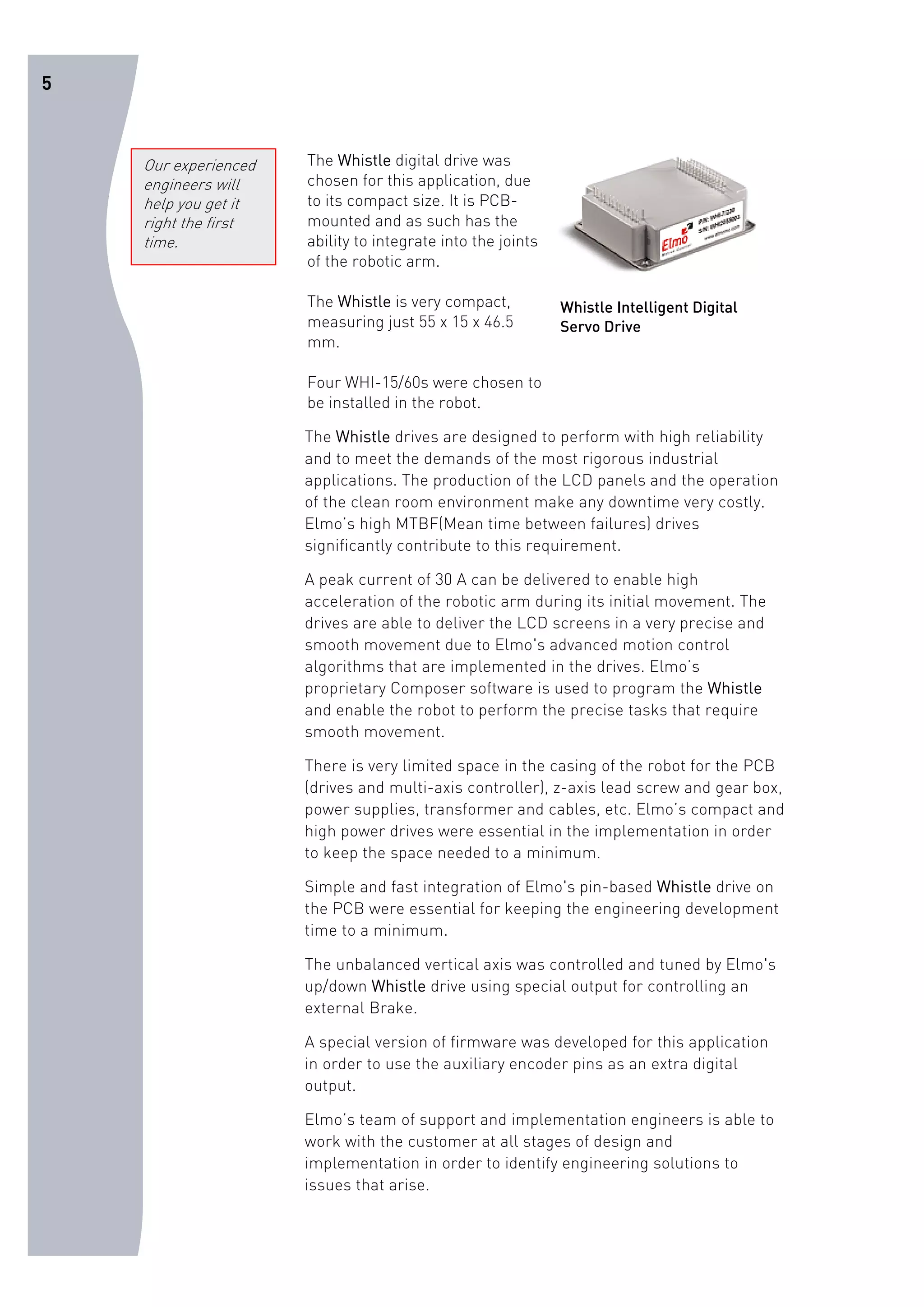

A robotics company needed drives for a clean room robot that transfers LCD panels. The robot required small, high-power drives for its four degrees of freedom within a limited space. Elmo's Whistle drives were chosen due to their compact size, ability to provide up to 3.3 kW of power, and ease of integration onto a printed circuit board. The Whistle drives enabled the robot to perform smooth, fast movements needed to precisely transfer LCD panels in the clean room.