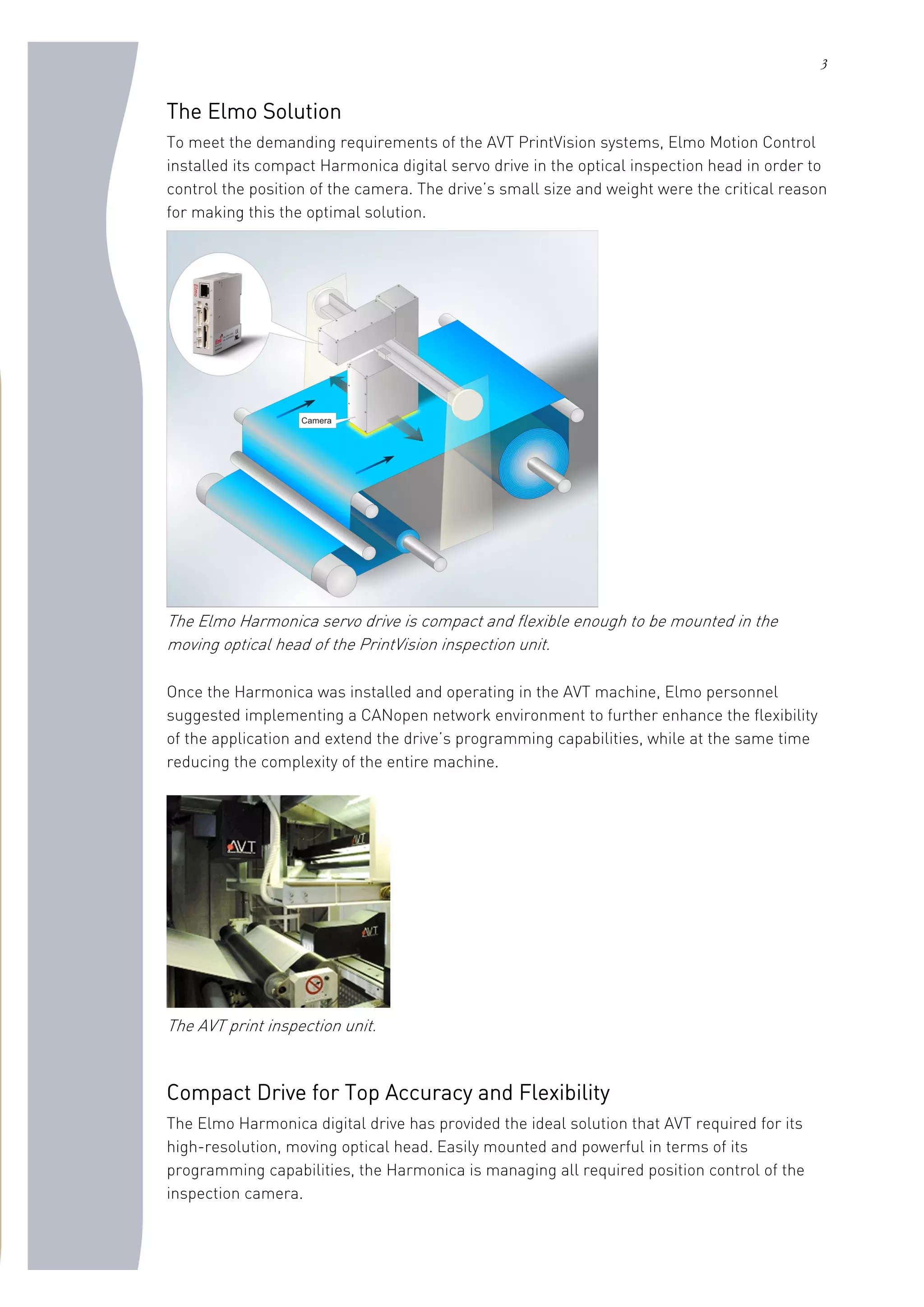

Elmo Motion Control has integrated its compact Harmonica digital servo drive into an automated print inspection machine developed by Advanced Vision Technology (AVT) to improve quality control in printing. The Harmonica servo drive controls the position of a high-resolution camera, allowing for real-time detection of printing defects, which reduces waste and enhances efficiency. The drive's small size and programmable features make it an optimal solution for AVT's print inspection systems, ensuring precise movement at high speeds.