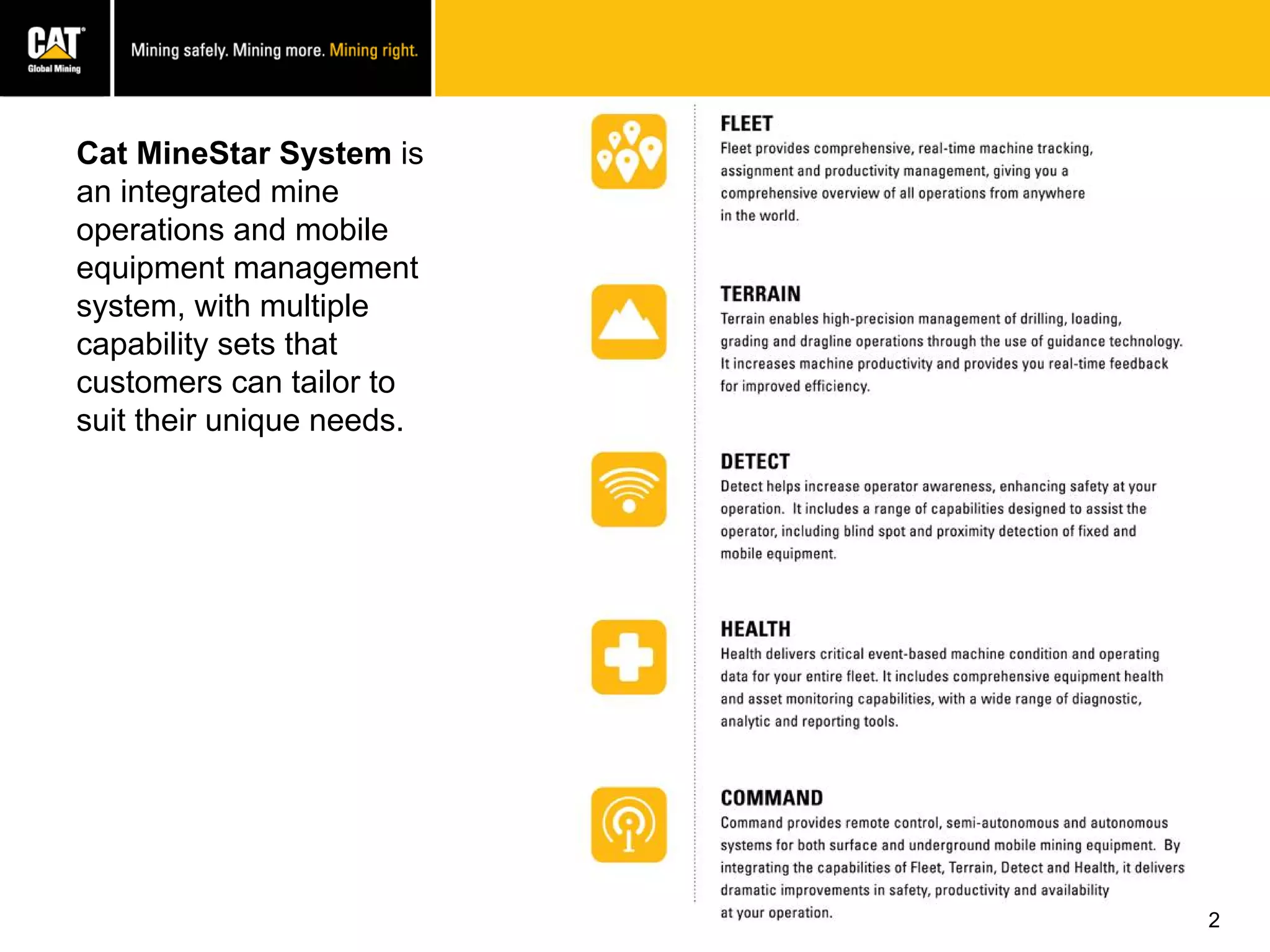

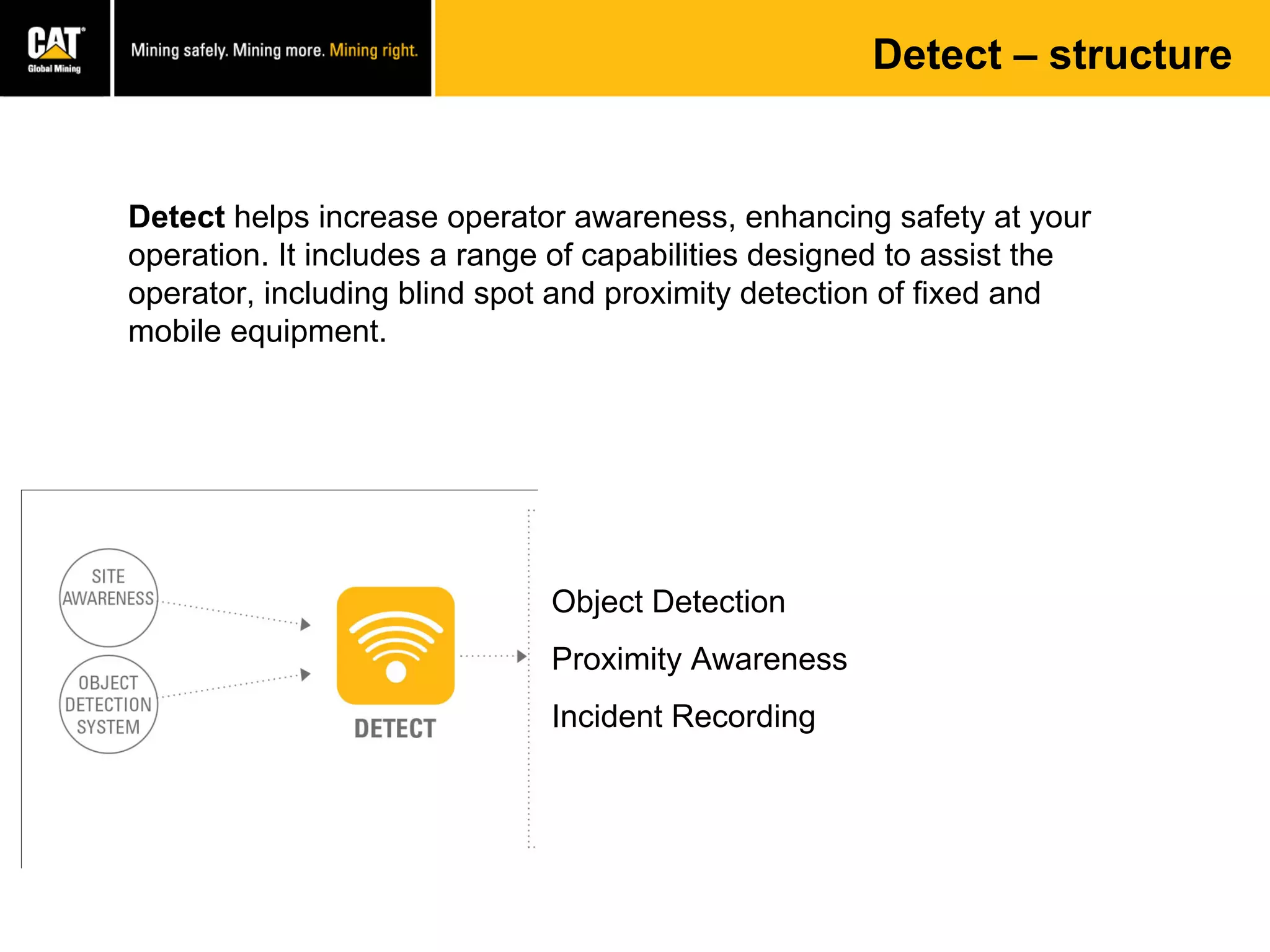

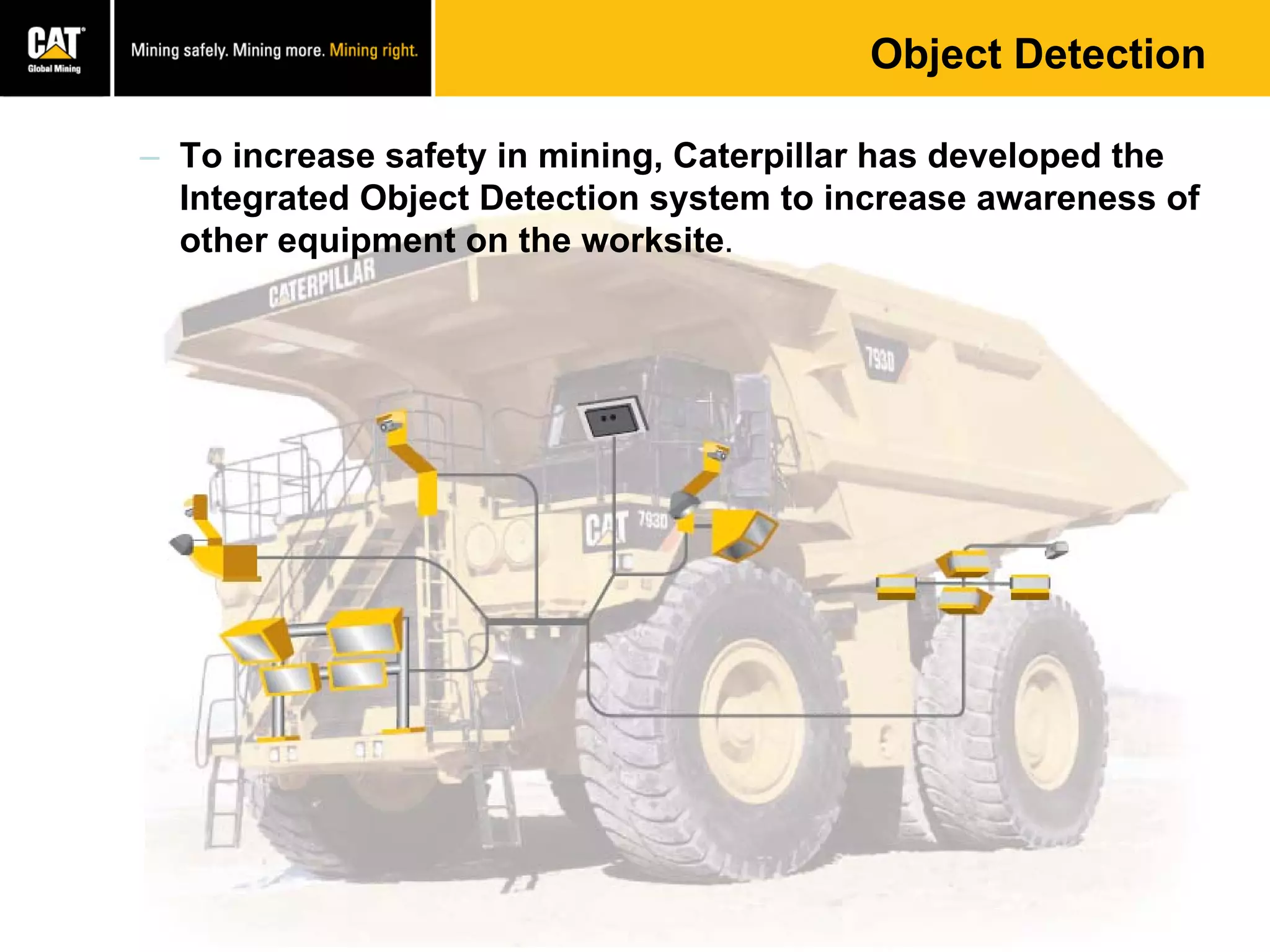

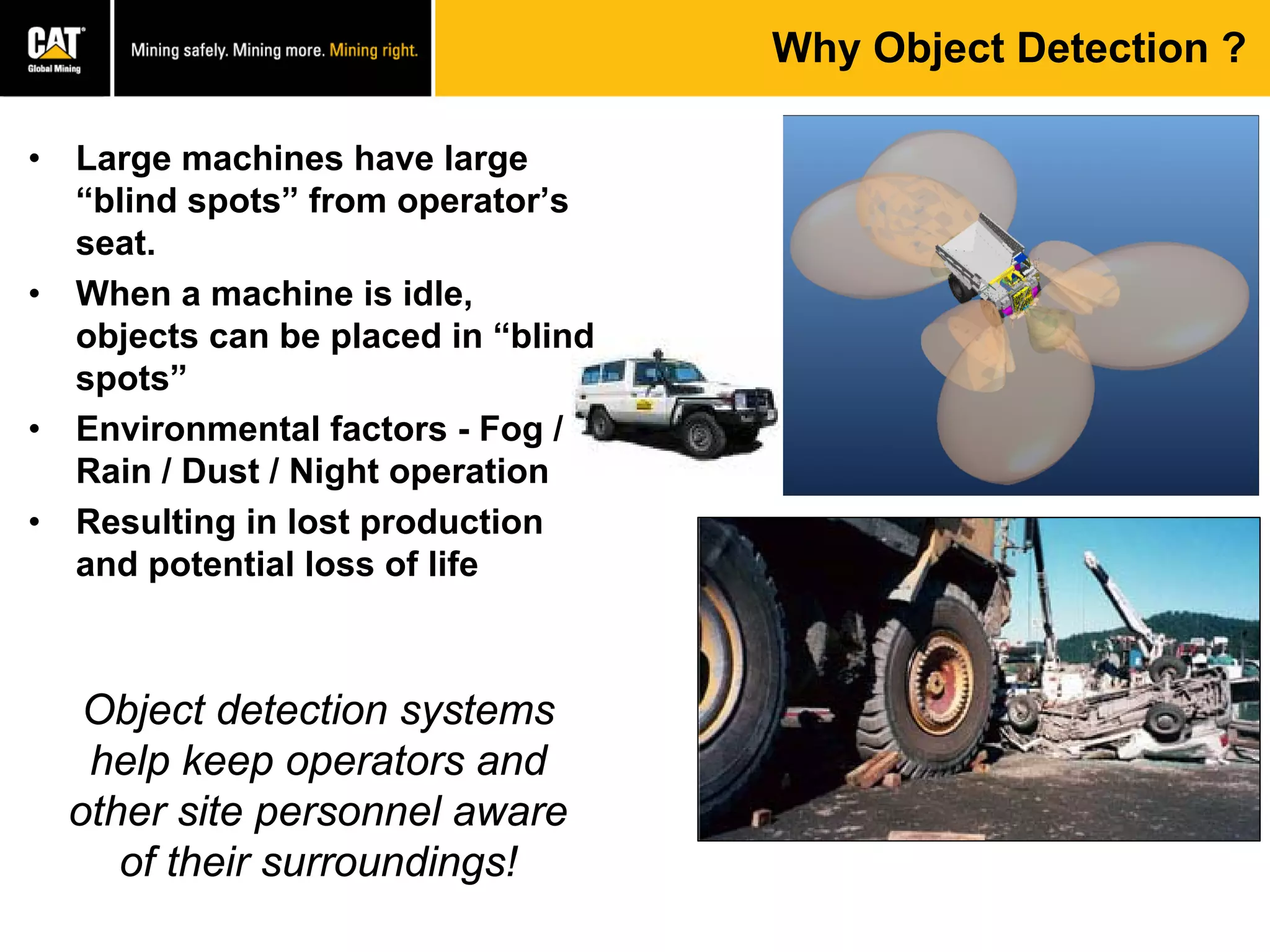

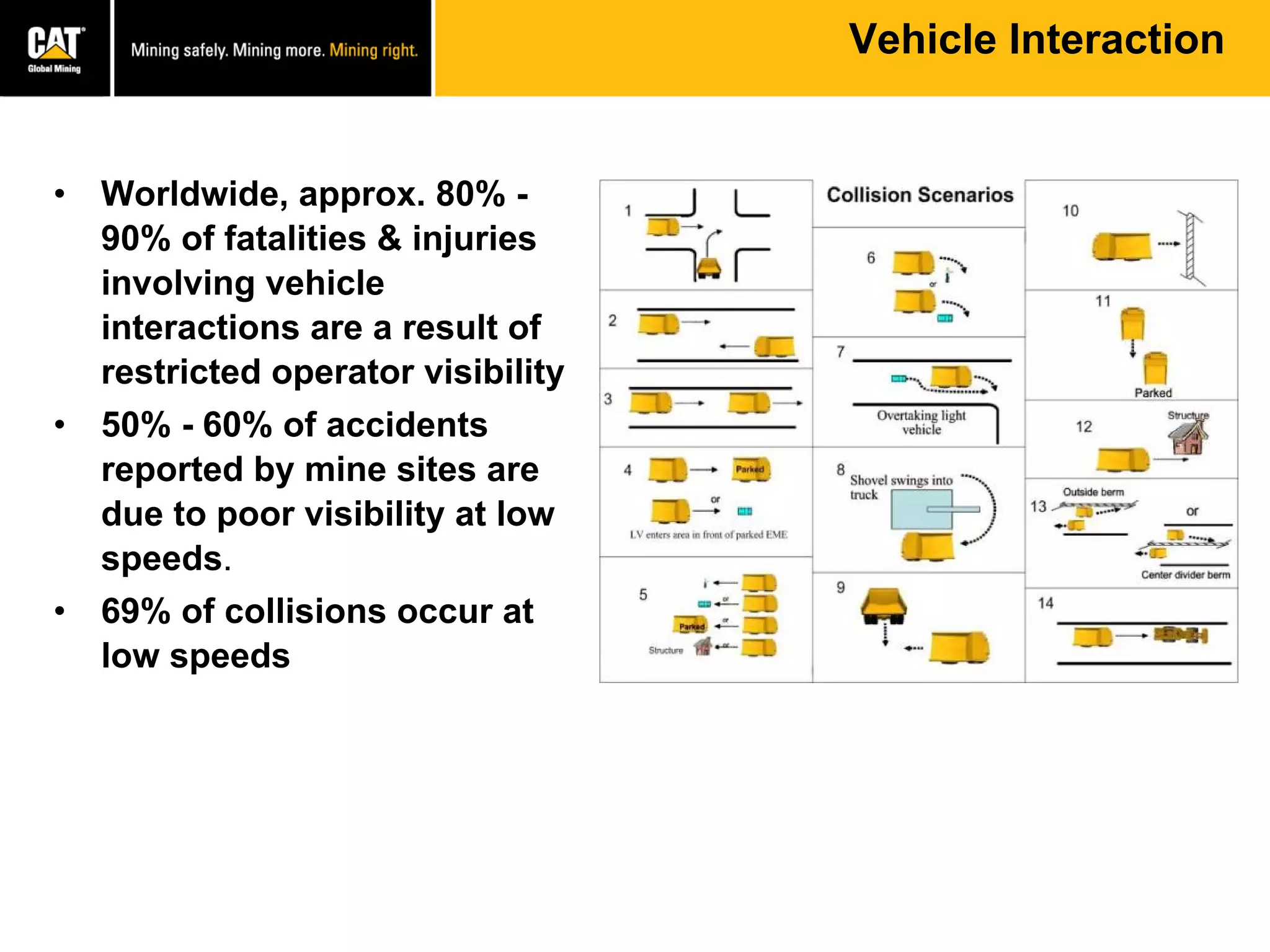

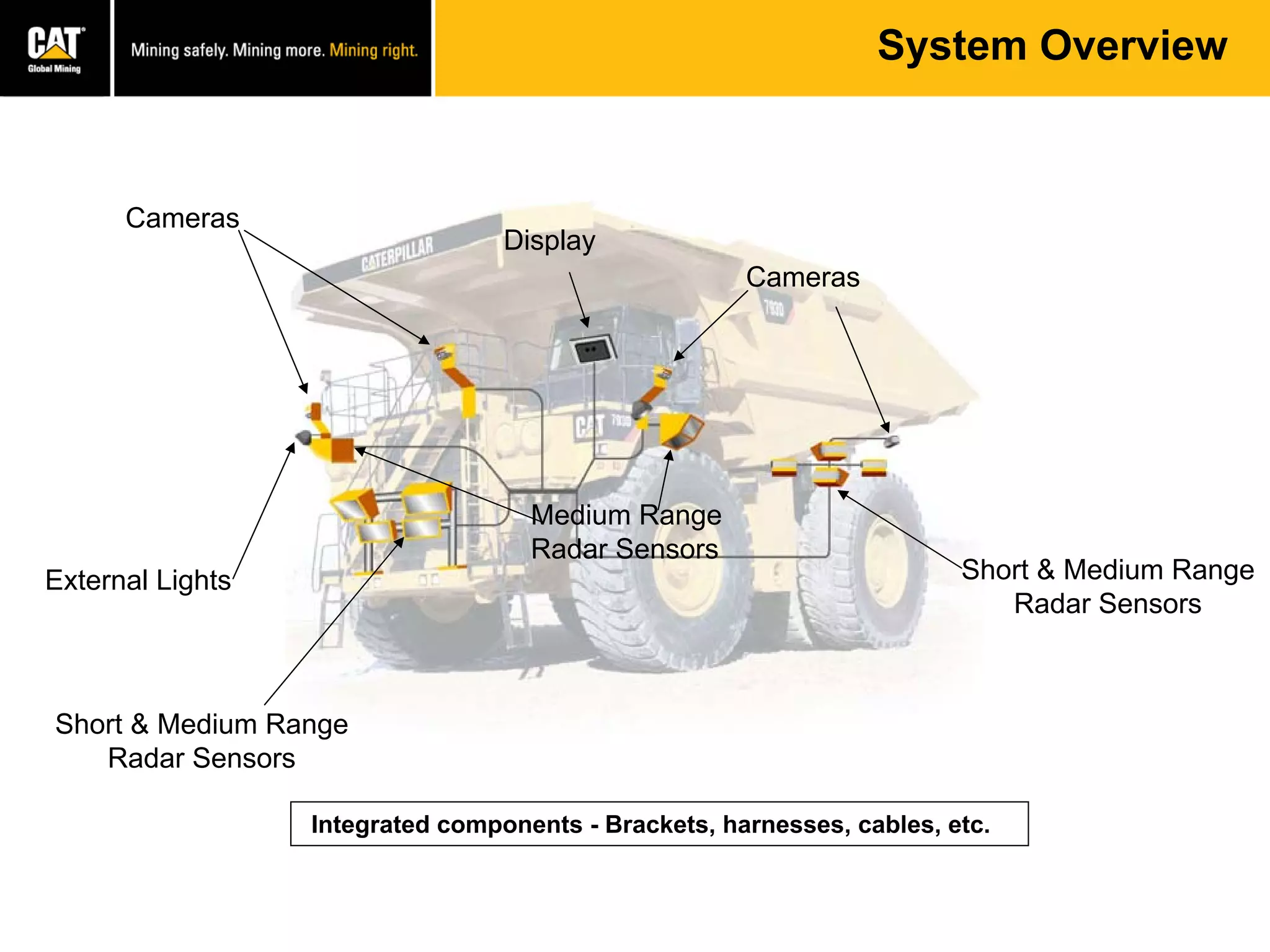

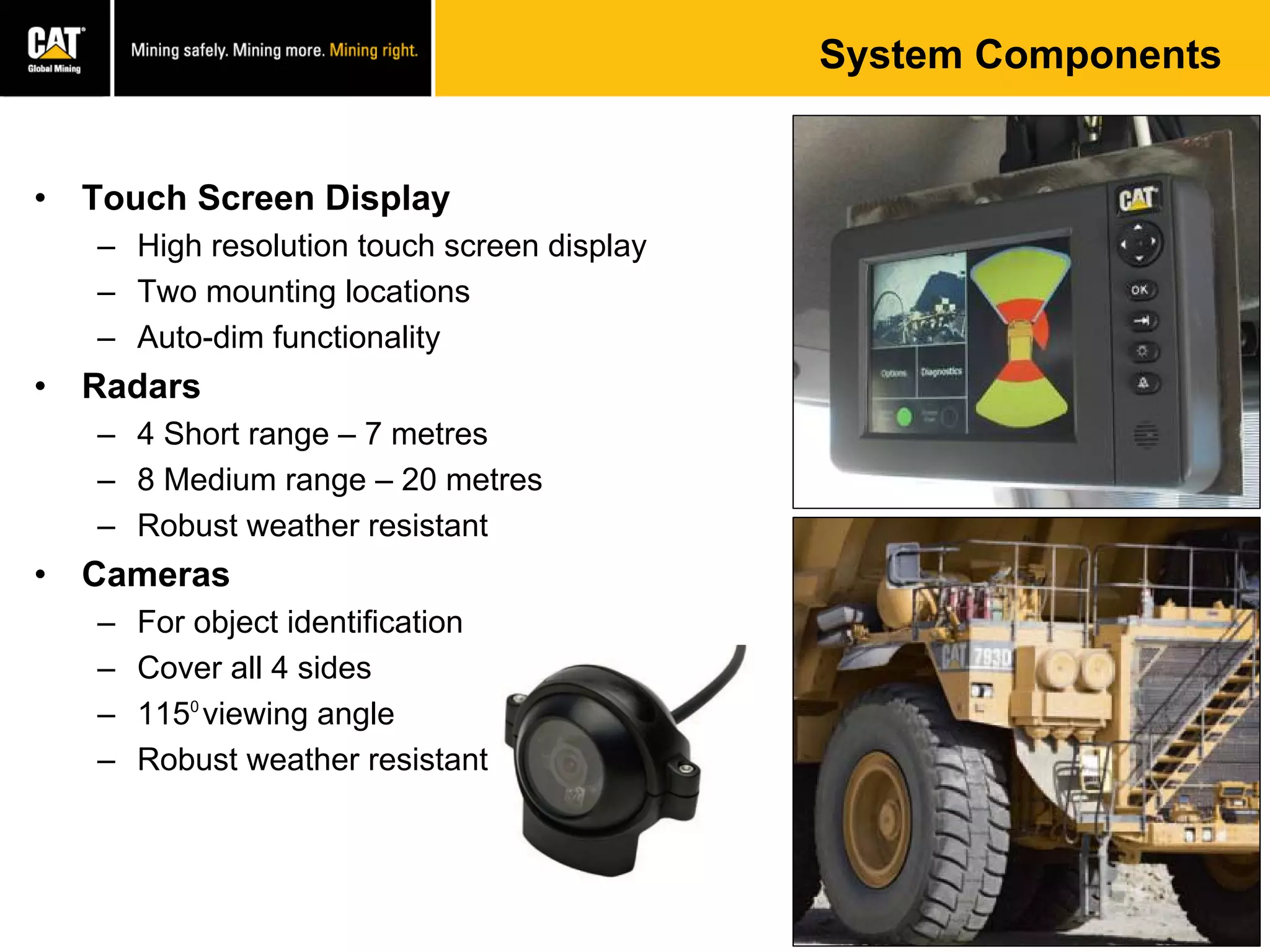

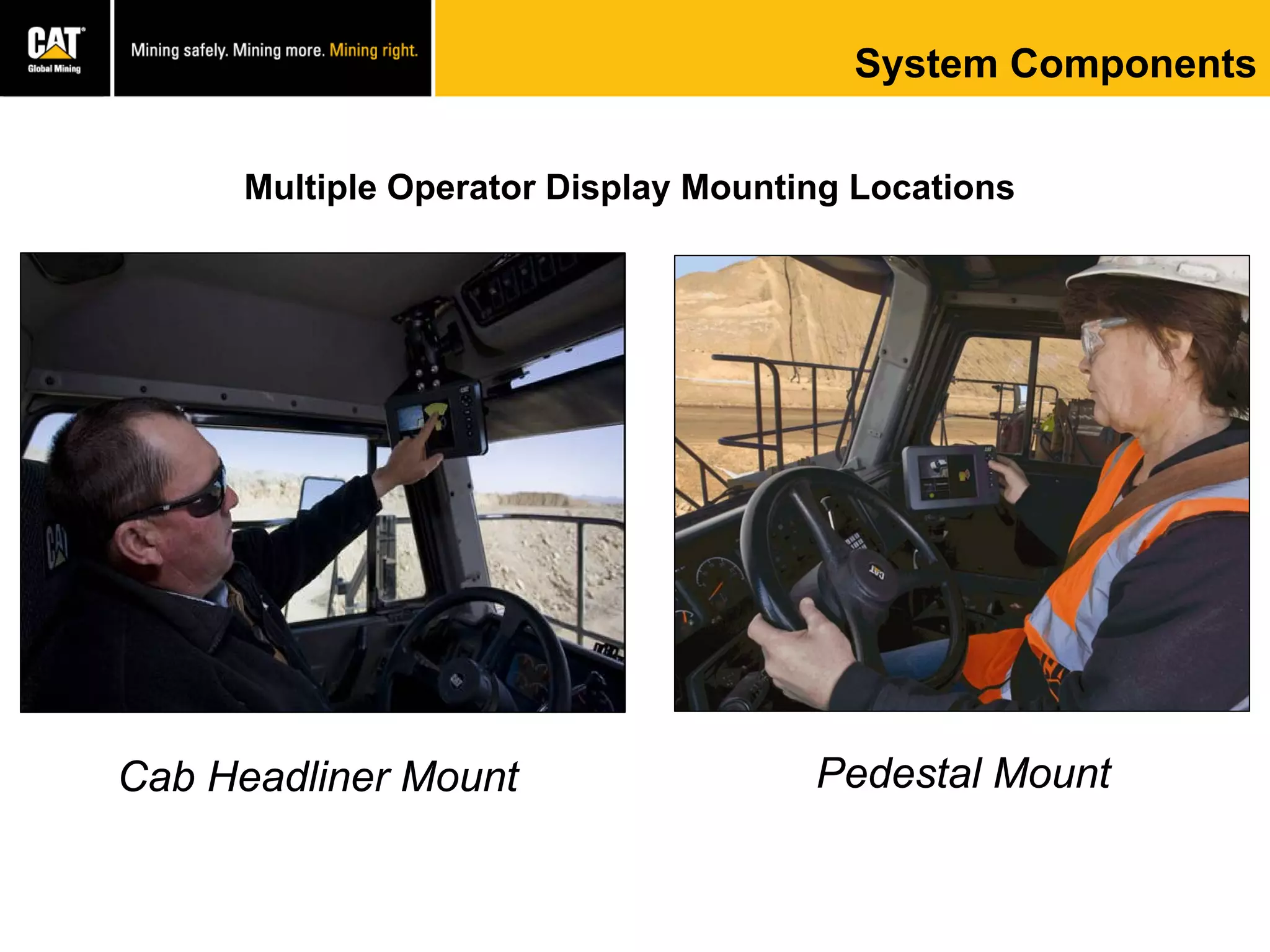

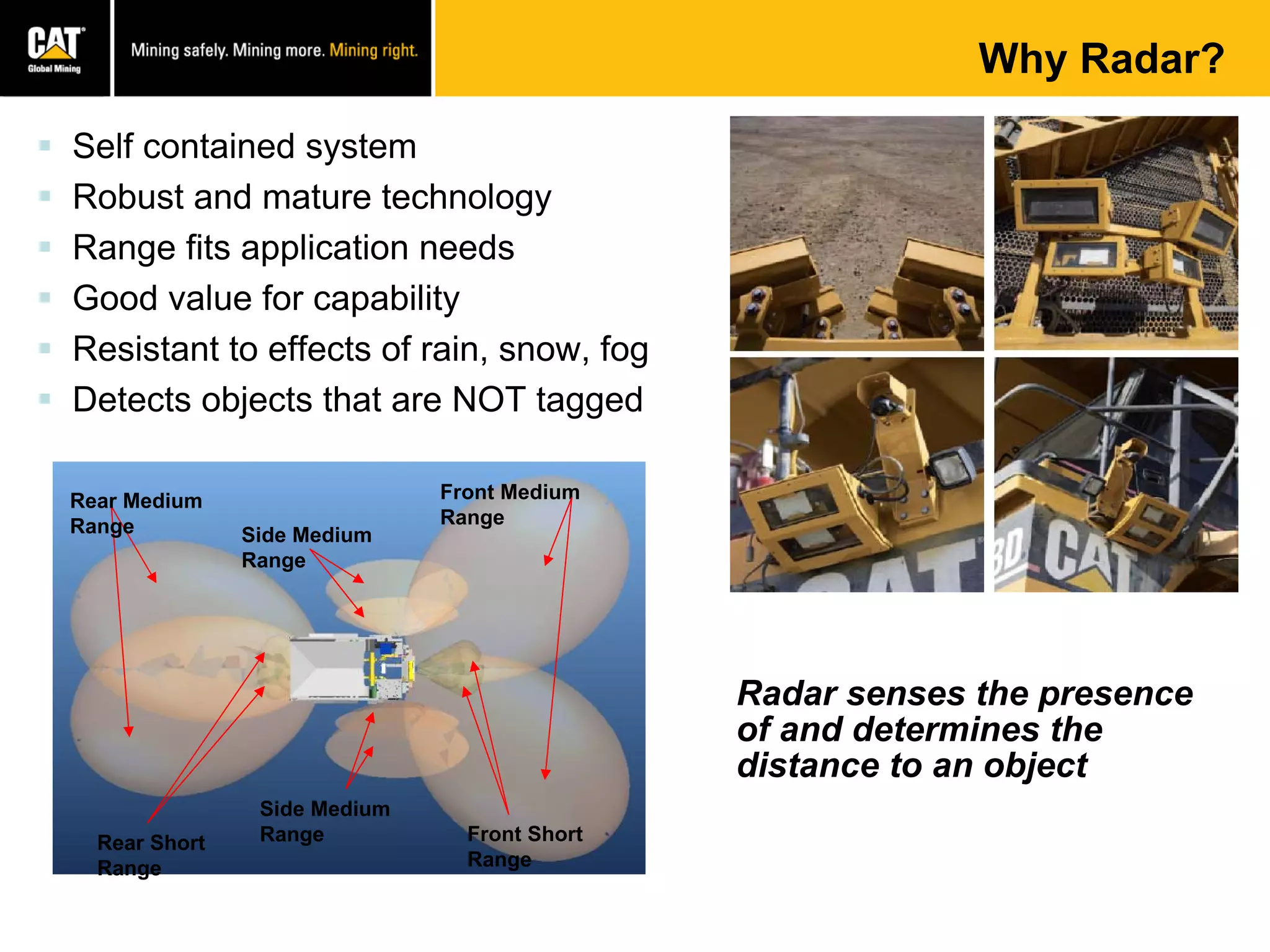

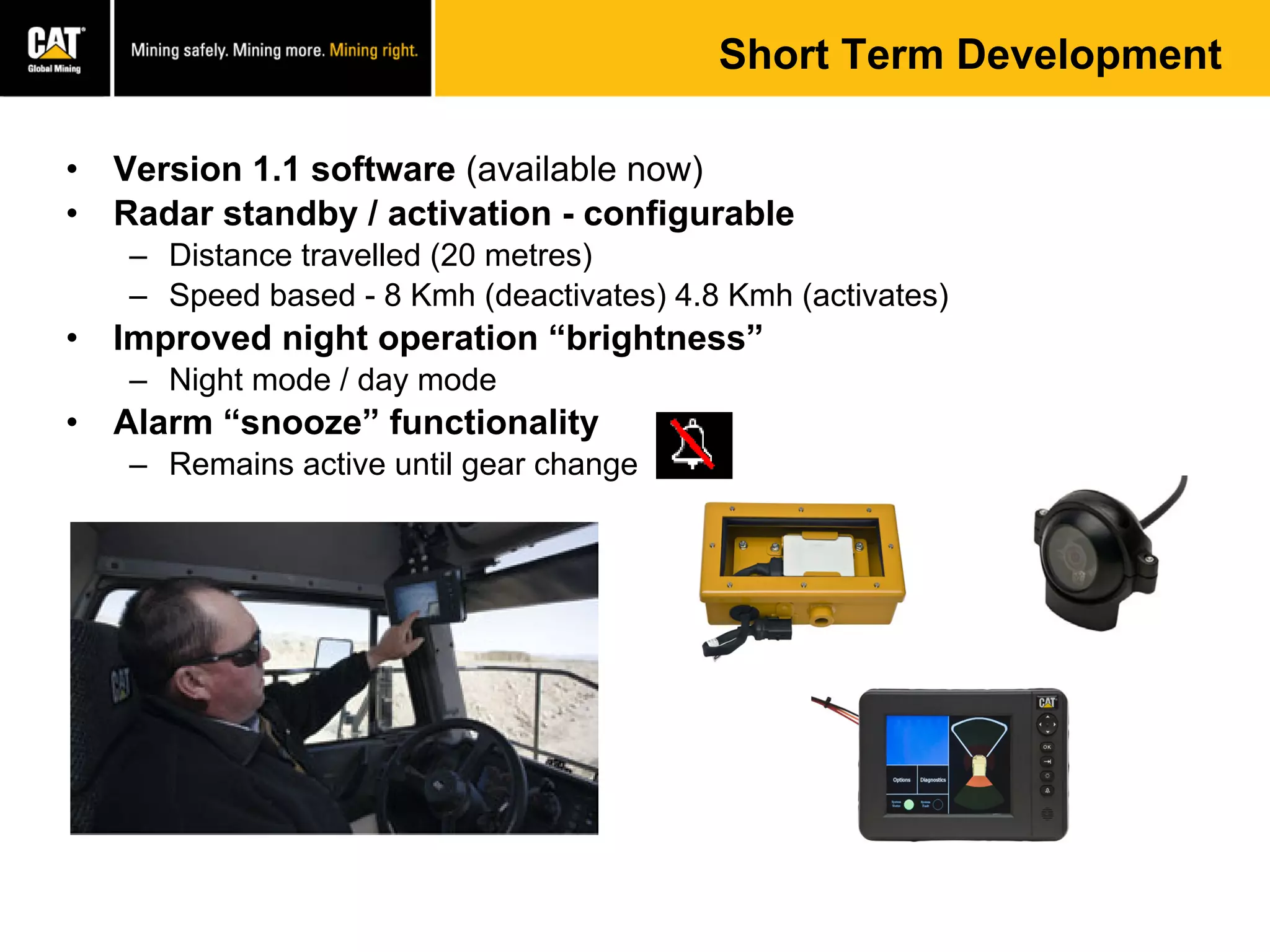

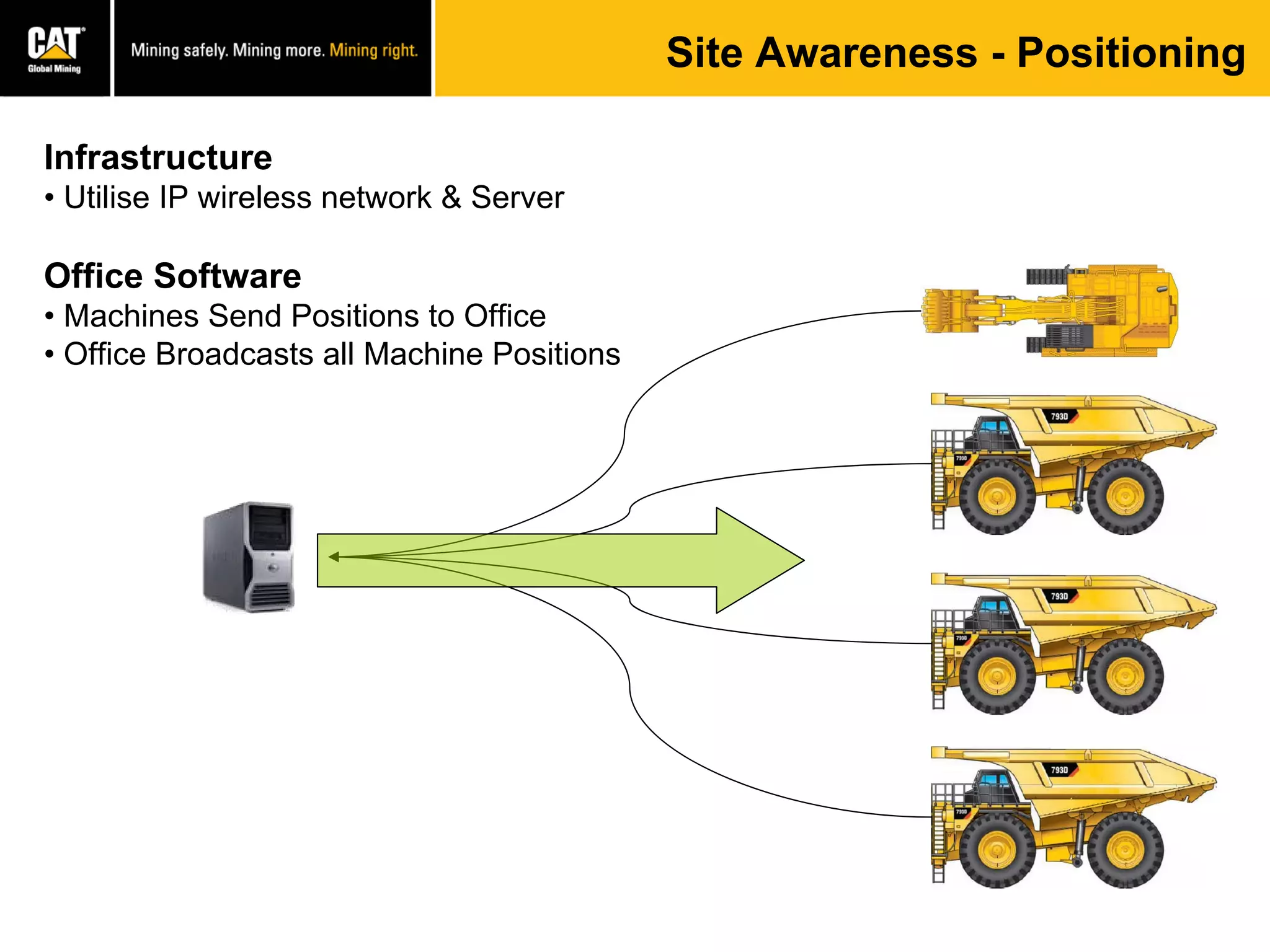

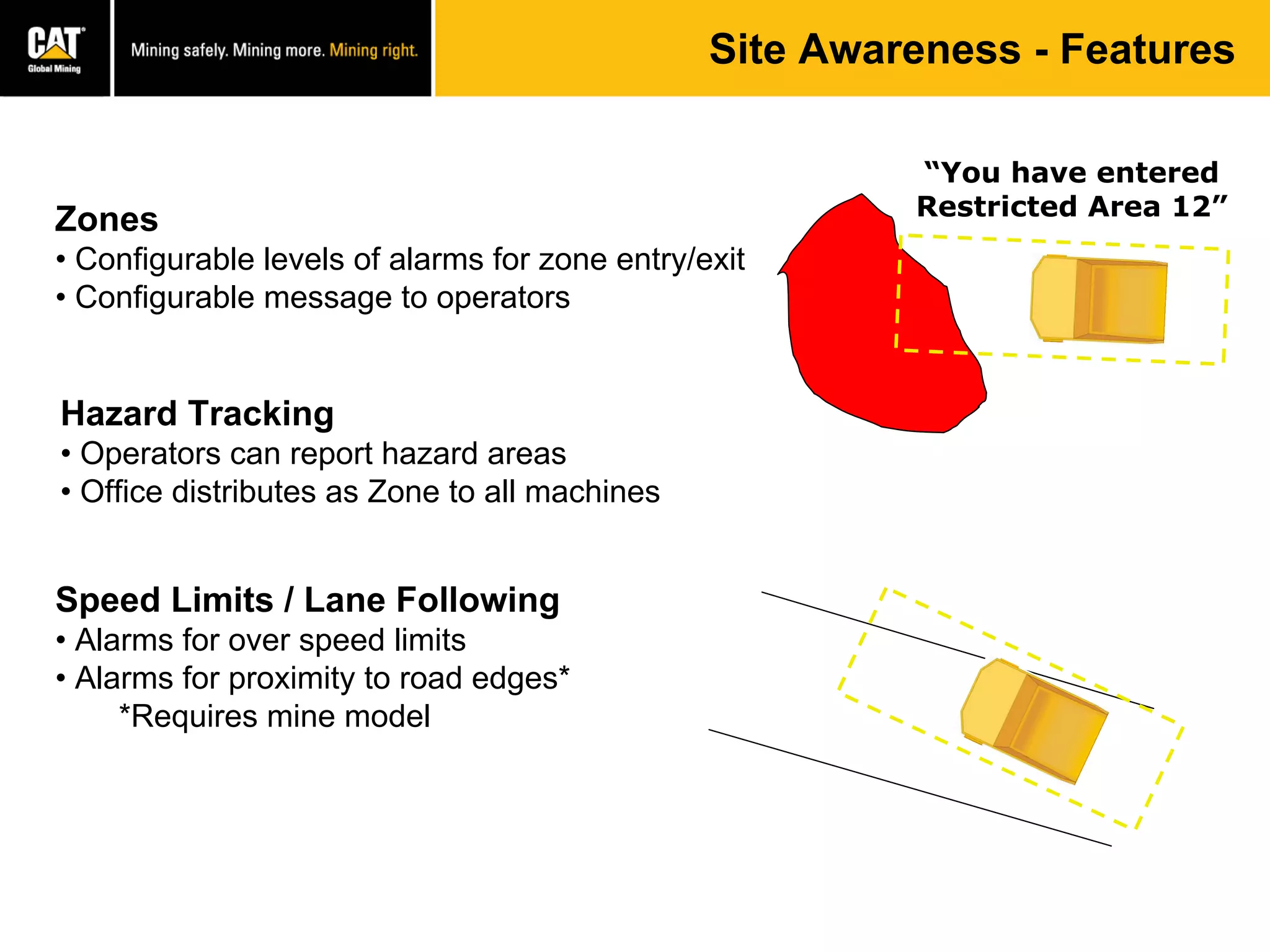

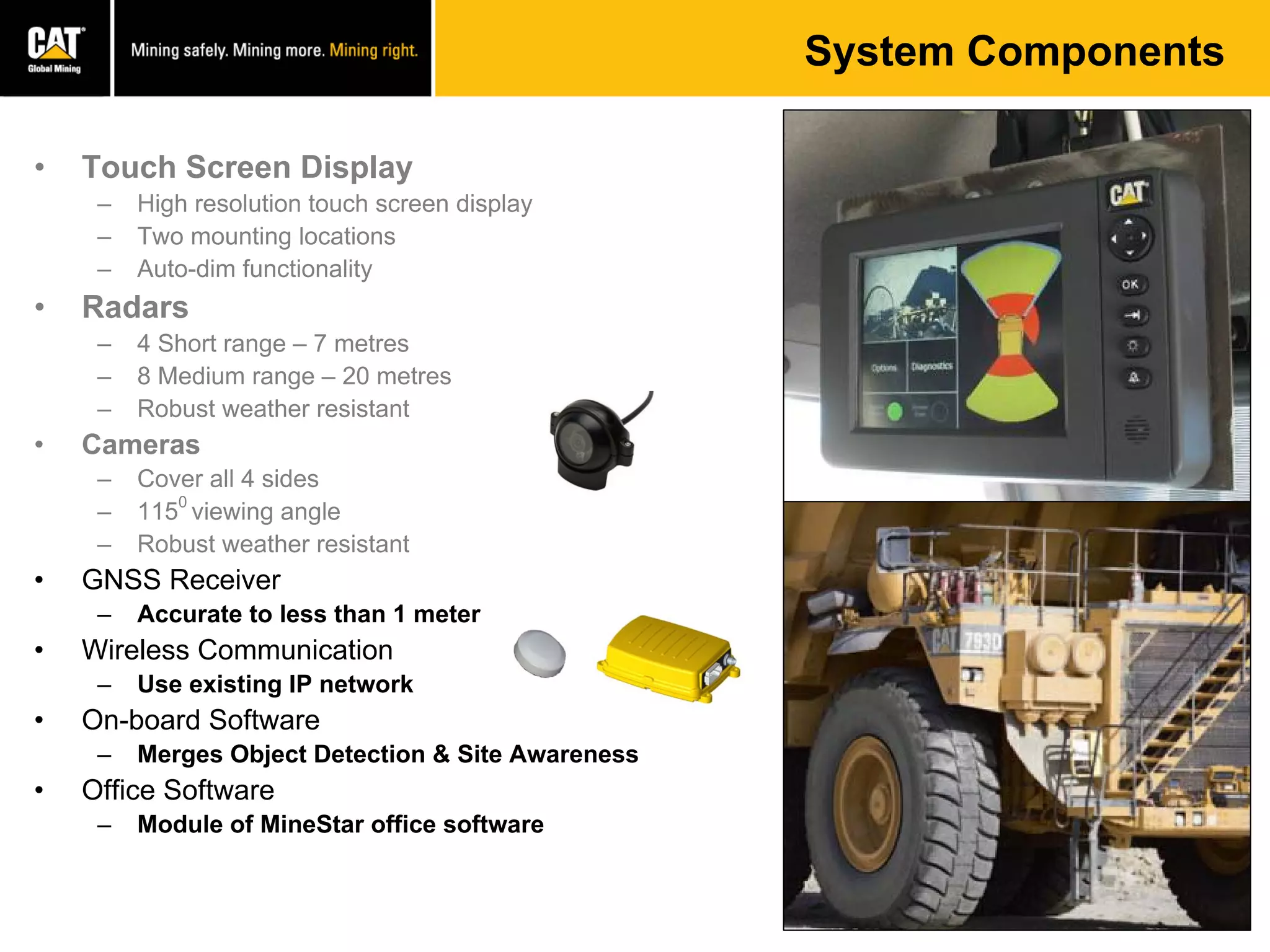

Caterpillar has developed an integrated object detection and site awareness system to increase safety in mining operations. The system uses radar, cameras, and GPS to detect nearby equipment, monitor machine locations, and alert operators of potential hazards. It is designed to work across Caterpillar's equipment lines and integrate with their MineStar fleet management software to provide a comprehensive solution for increasing awareness and avoiding collisions.