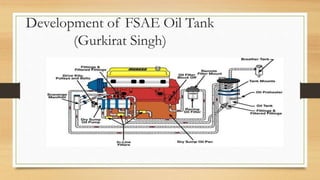

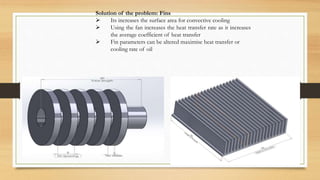

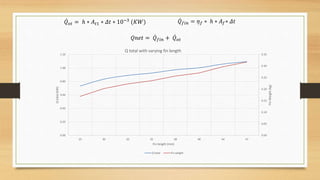

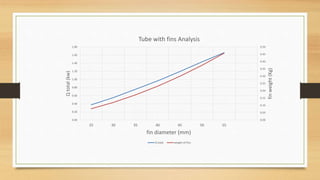

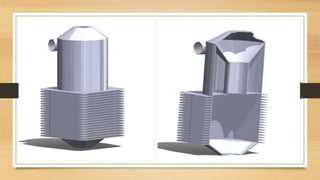

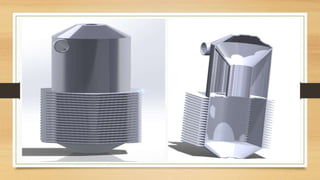

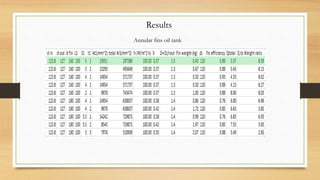

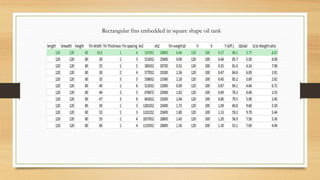

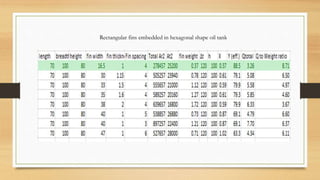

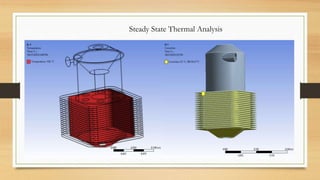

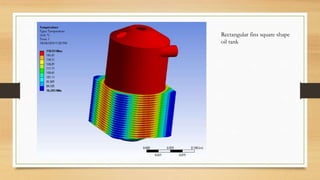

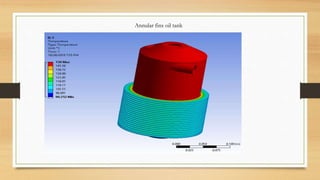

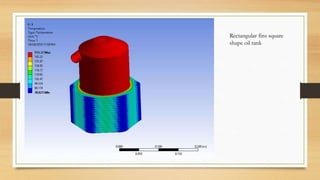

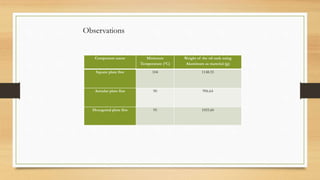

The document discusses the development of an oil tank cooling system for an FSAE race car. It notes that effective cooling is needed to prevent oil breakdown at high temperatures and reduce engine wear. Various fin designs are analyzed and tested, including rectangular fins embedded in square and hexagonal tanks and annular fins. Thermal analysis shows that while hexagonal fins have a higher heat sink rate, the annular fin design most effectively lowers oil temperature with less weight. In conclusion, an annular fin arrangement provides the best cooling for the oil tank.