This document provides information about cooling towers, including:

1. Definitions of key cooling tower terminology such as tons and wet bulb temperature and how they impact tower capacity.

2. An overview of EVAPCO's product offerings for induced draft and forced draft cooling towers ranging in size from 27 to 1,332 tons.

3. An explanation of the principle of operation for induced draft and forced draft towers, which can be counterflow or crossflow.

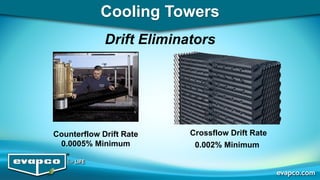

4. A description of key cooling tower components like fill material, drift eliminators, basins, and distribution systems.

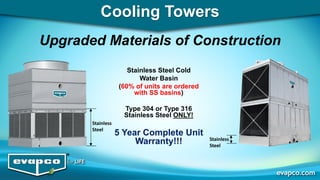

5. Details on maintenance access points, materials of construction including upgrades to stainless steel, and structural design requirements.