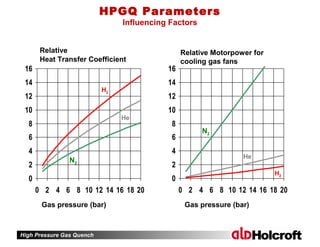

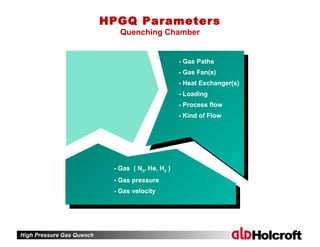

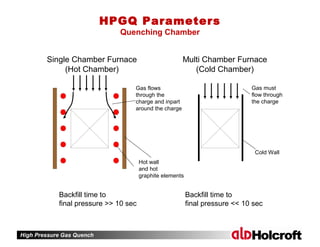

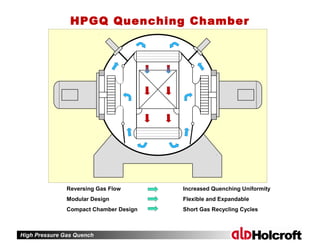

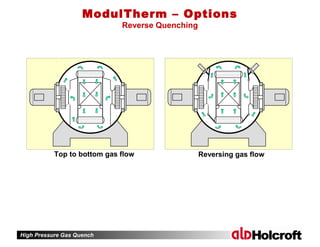

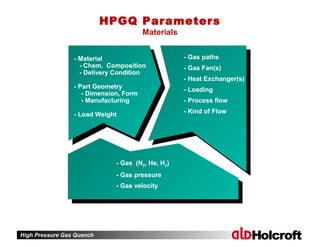

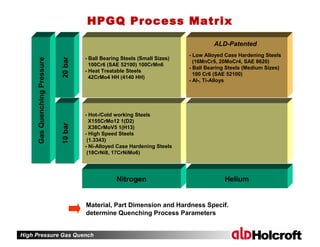

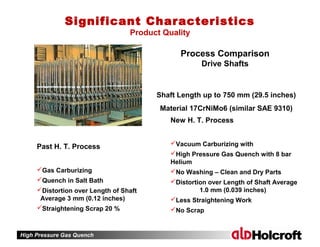

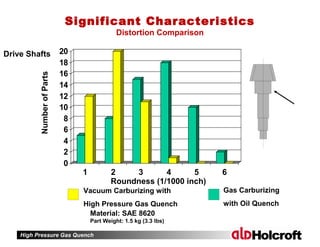

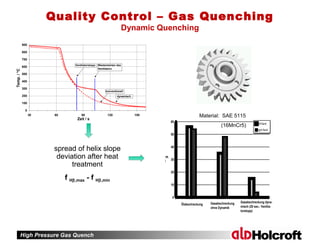

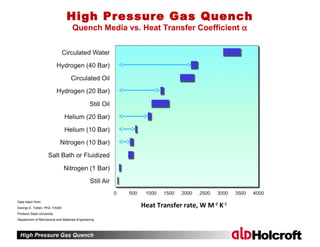

High pressure gas quenching (HPGQ) offers advantages like reduced hardening distortion and adjustable quenching intensity through gas pressure and velocity. This clean and non-toxic process integrates well into manufacturing lines, producing reproducible and high-quality results without the need for washing. Key parameters influencing HPGQ include gas type, pressure, velocity, and chamber design, which collectively impact the material's microstructure, hardness, and overall distortion.

![High Pressure Gas Quench

Bubble Boiling

Film Boiling

Convection

t = 10 s

750°C

700°C

700°C

600°C

500°C

400°C

300°C

200°C

Temperature distribution

t = 10 s

Heat transfer coefficient α

5000 10000 15000 20000

Öl

oil Wasser

water

[W/m K]

2

ref.: Stick, Tensi, HTM 50, 1995

Heat Transfer & Temperature Distribution

Immersion Quenching](https://image.slidesharecdn.com/highpressuregasquenching-150328134521-conversion-gate01/85/High-Pressure-Gas-Quenching-5-320.jpg)

![High Pressure Gas Quench

Heat transfer coefficient α

1000 2000 3000 4000 [W/m K]

2

Temperature distribution

750°C

650°C

550°C

450°C

350°C

250°C

Gas direction

Only convection

Heat Transfer & Temperature Distribution

High Pressure Gas Quenching](https://image.slidesharecdn.com/highpressuregasquenching-150328134521-conversion-gate01/85/High-Pressure-Gas-Quenching-6-320.jpg)