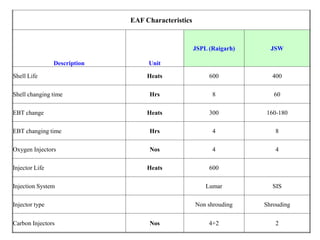

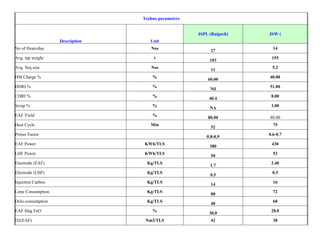

The plant visit report summarizes key characteristics and parameters of the electric arc furnace (EAF) at JSPL Raigarh and JSW. Some key differences highlighted include:

- JSPL Raigarh's EAF shell lasts 600 heats compared to 400 heats for JSW's shell.

- JSPL Raigarh has more facilities like charging cranes, coke filling cranes, and spare transformers.

- JSPL Raigarh produces more heats per day (27 vs 14) and has a higher average tap weight (103t vs 155t) compared to JSW.

- JSPL Raigarh uses a higher percentage of hot