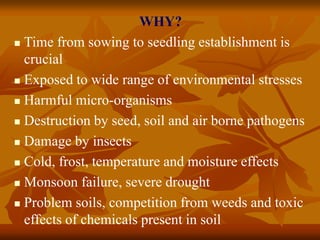

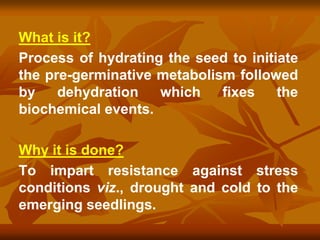

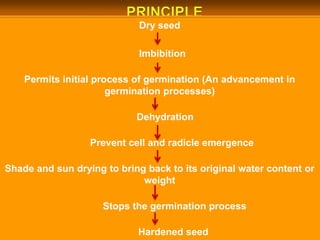

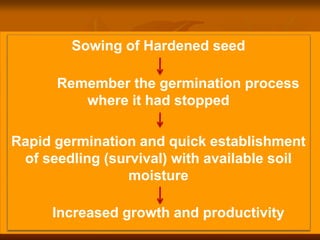

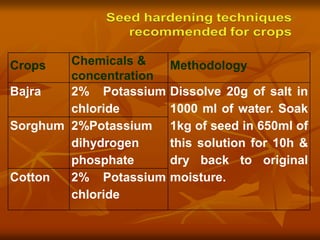

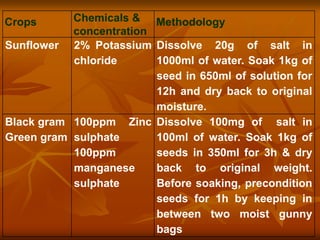

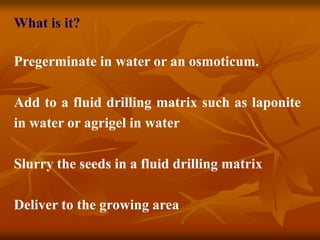

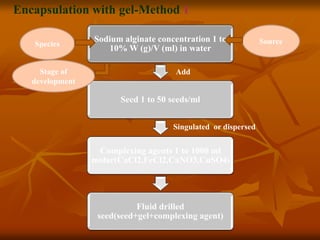

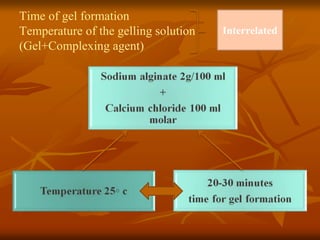

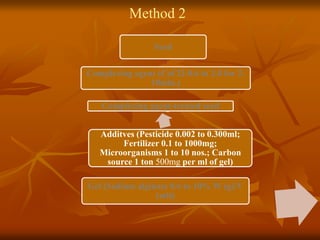

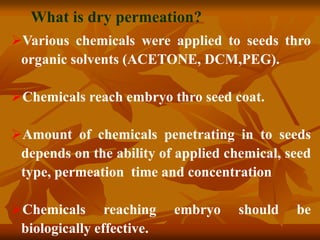

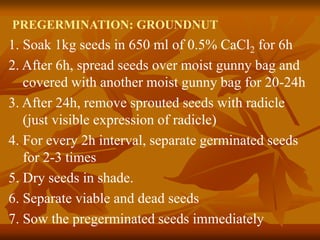

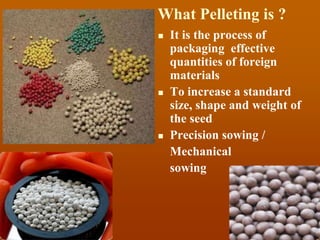

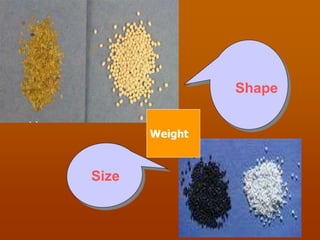

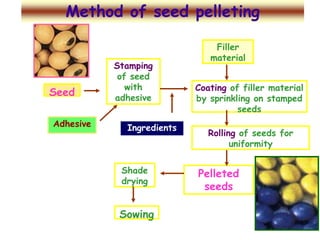

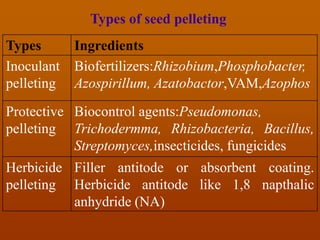

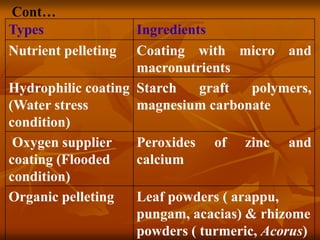

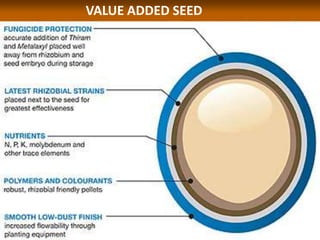

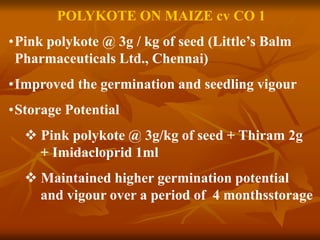

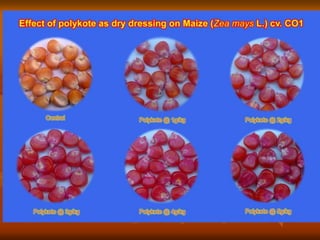

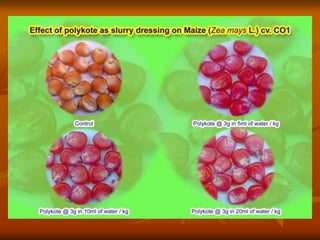

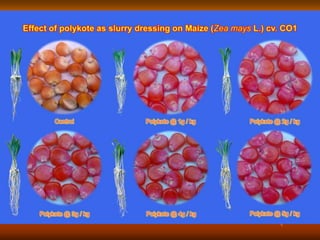

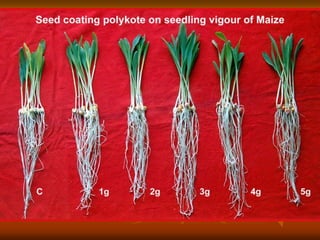

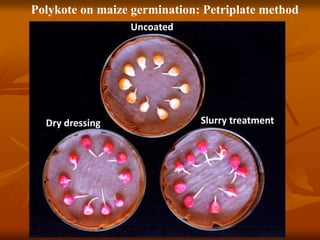

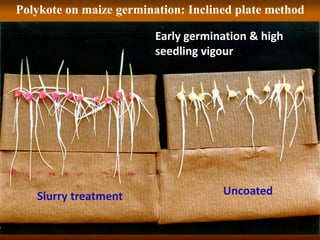

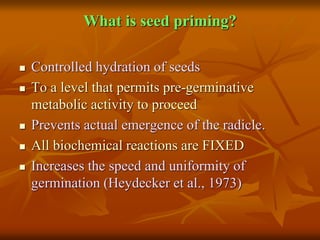

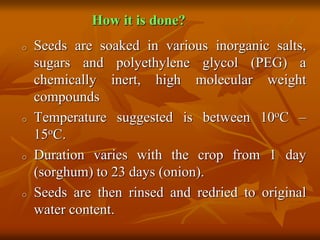

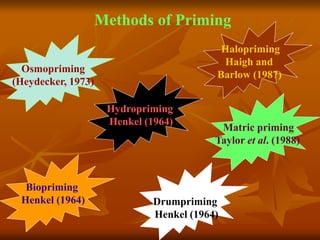

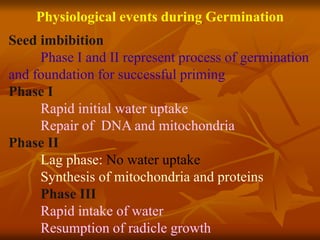

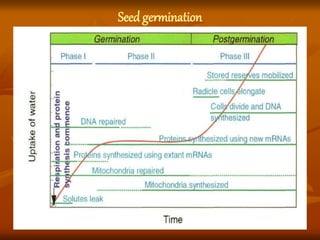

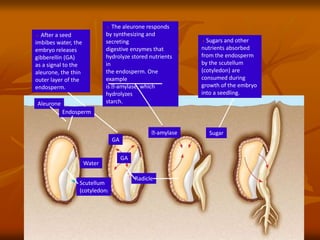

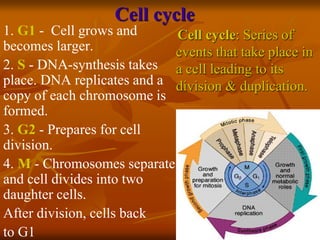

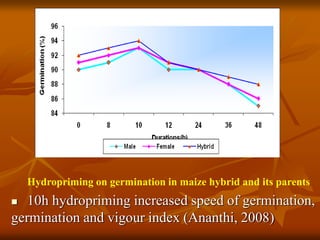

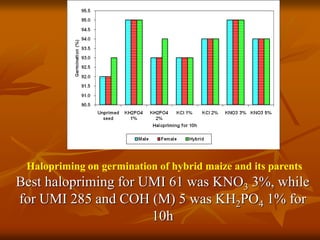

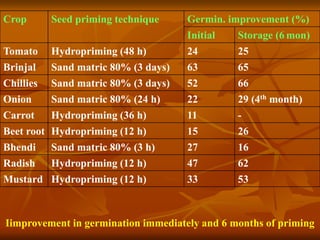

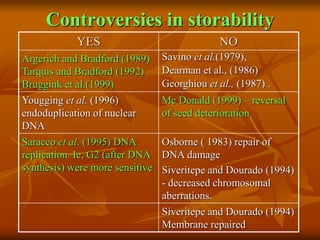

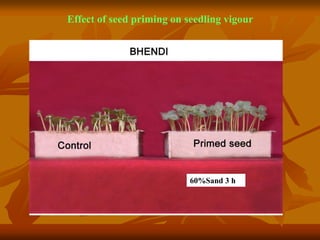

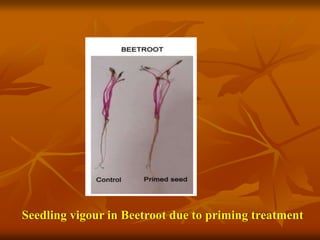

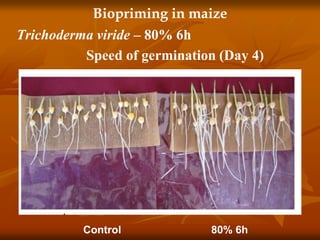

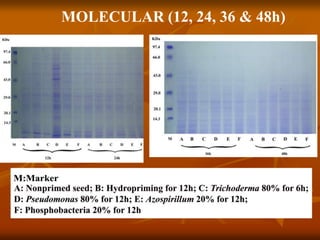

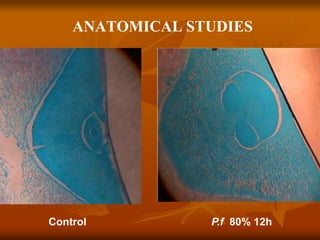

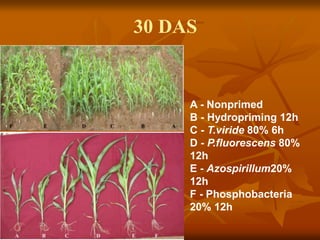

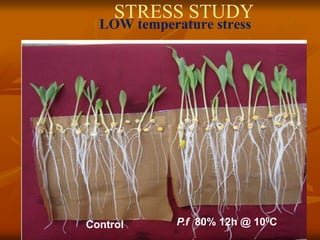

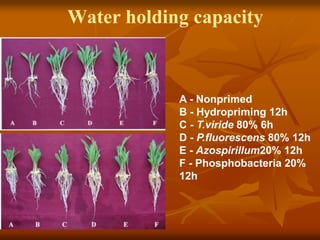

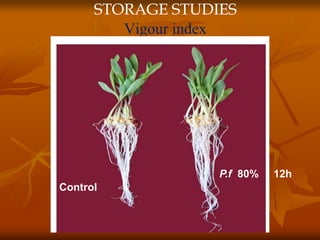

The document discusses seed quality enhancement techniques, emphasizing various methods such as dormancy breaking treatments, seed priming, and pelleting to improve germination and seedling vigor. It details processes for different crops and chemical treatments, as well as the physiological effects of treatments on seed performance. The document also covers advances in seed pelleting and the importance of proper seed conditioning for resistance against environmental stresses.