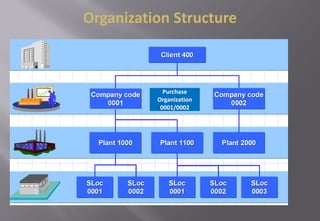

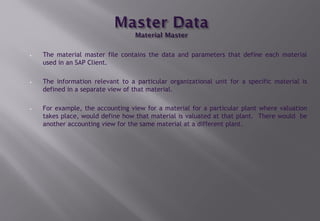

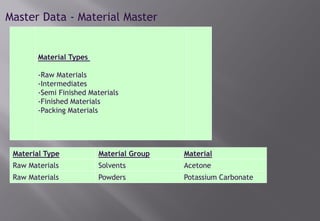

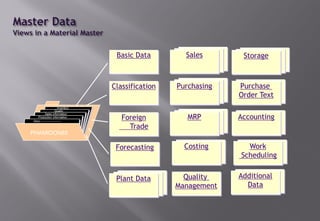

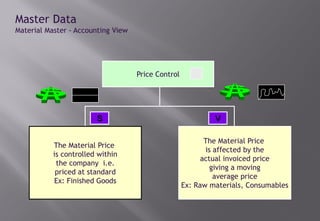

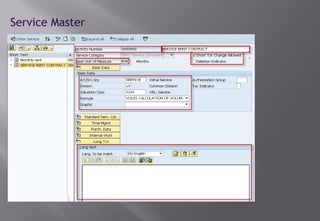

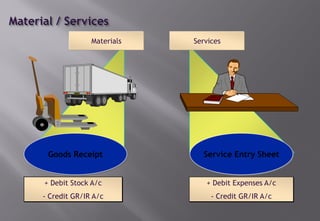

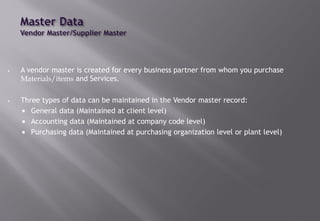

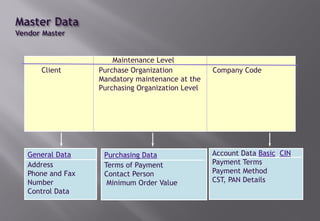

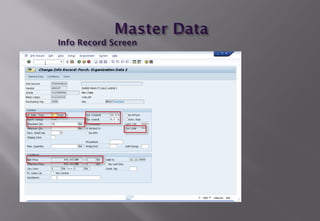

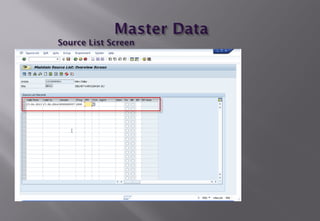

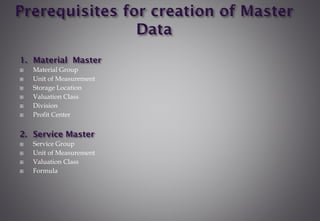

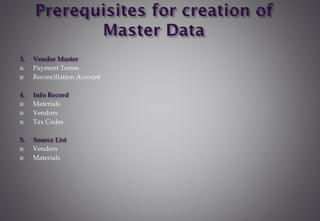

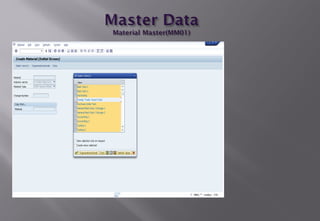

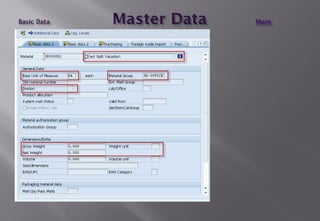

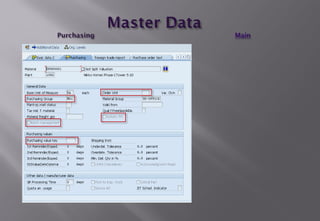

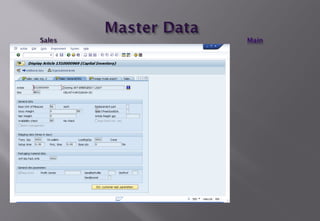

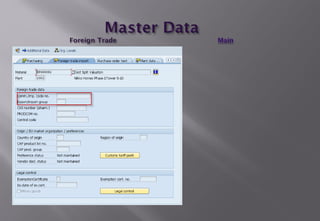

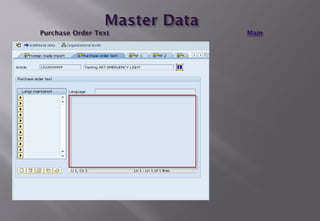

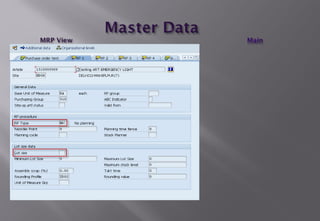

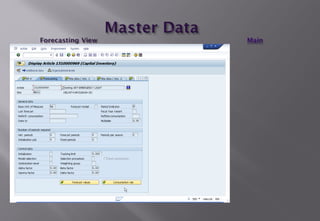

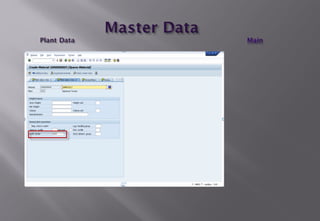

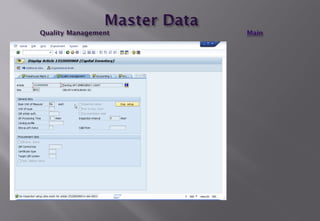

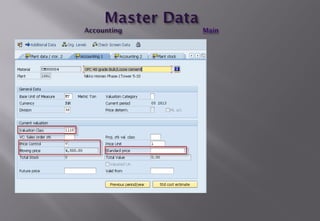

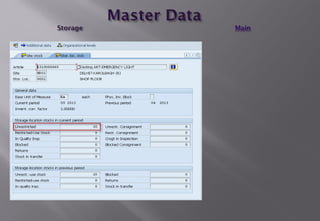

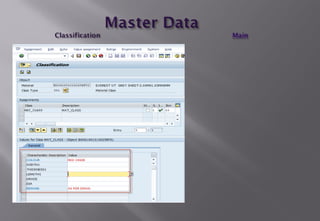

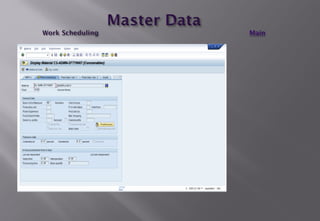

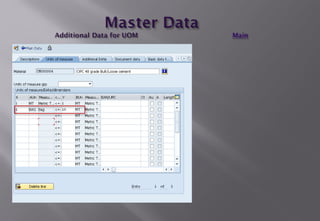

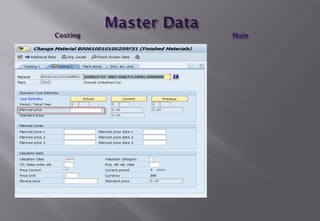

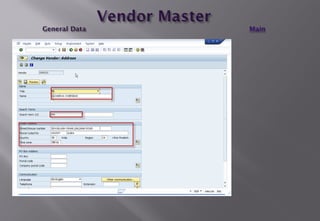

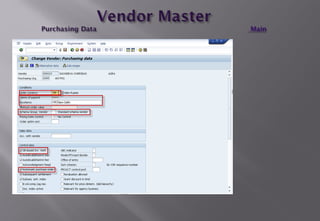

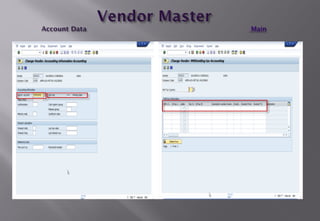

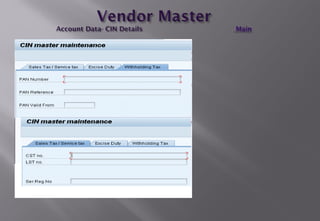

The document provides an overview of master data in SAP's materials management (MM), which includes the organization of procurement, inventory, and valuation of materials. It outlines key components like material master, service master, vendor master, info records, and source lists, detailing how they interact within the supply chain. Key data points such as pricing, purchasing information, and organizational structures are also highlighted, emphasizing the importance of accurate master data management.